Battery cartridge holder

A battery and boxing technology, which is applied in the direction of battery assembly machine, secondary battery manufacturing, manipulator, etc., can solve the problems of low efficiency and high labor intensity, so as to improve the grasping speed and detachment speed, improve work efficiency and reduce workers The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

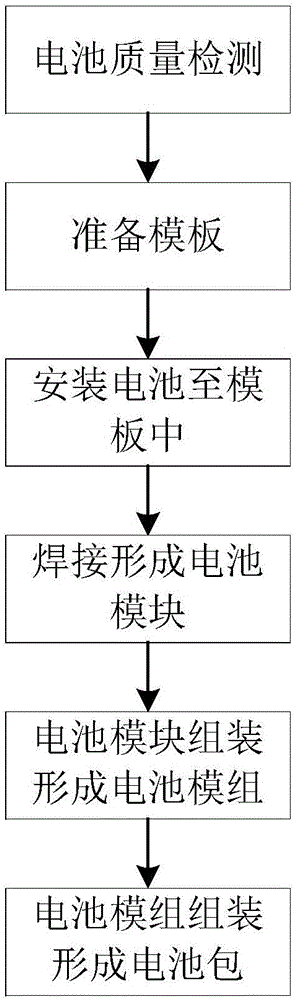

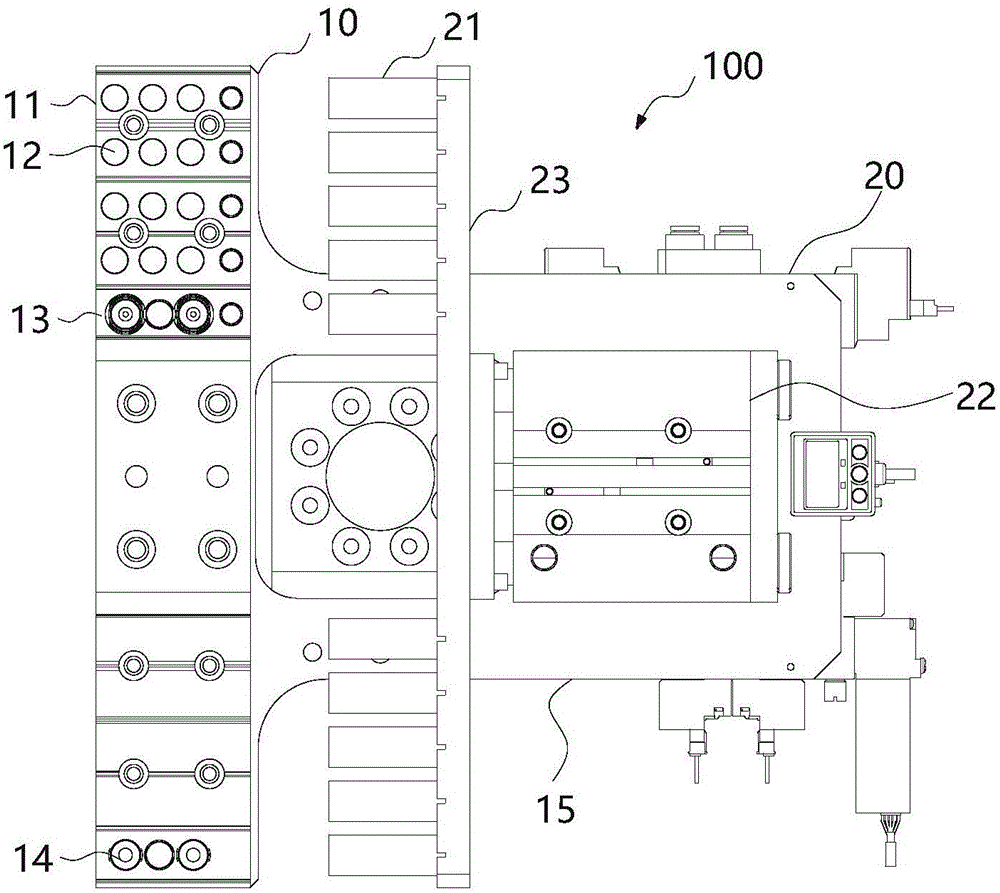

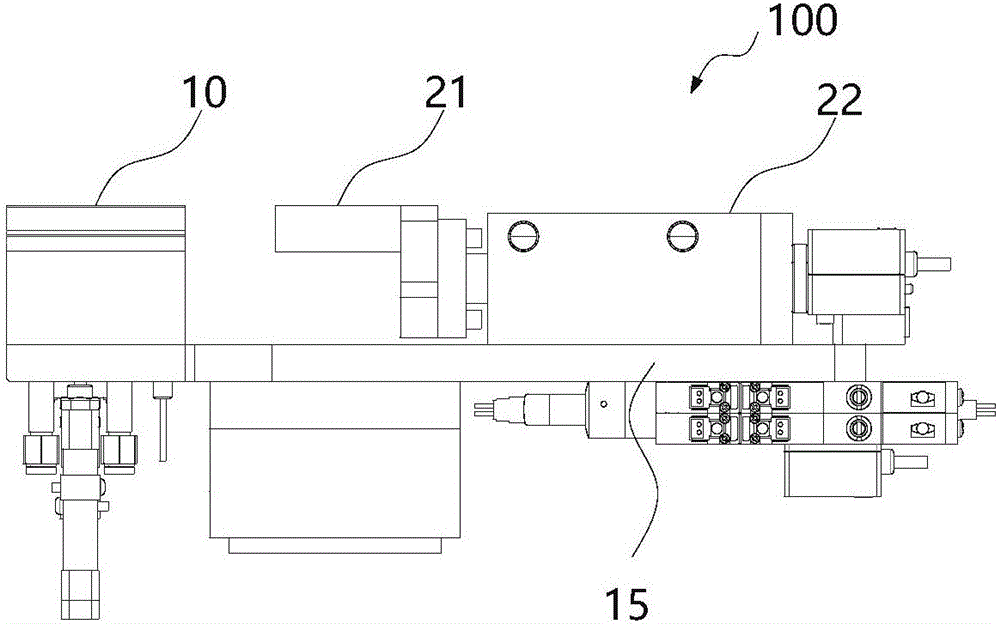

[0020] Such as figure 1 As shown, the present invention relates to the battery pack production system of the overturning device generally comprising the following process:

[0021] 1. First conduct quality inspection of the batteries to be used, and eliminate unqualified batteries;

[0022] 2. Prepare the bottom plate, top plate and conductive sheet with holes respectively, where the number of holes corresponds to the number of batteries to be installed;

[0023] 3. Use the installation device to put the battery into the hole on the bottom plate with the conductive sheet, buckle the top plate with the conductive sheet on the arranged batteries, and use the buckle to fix the bottom plate and the top plate together to form a battery module , the conductive strips on the top and bottom of the battery module face outward;

[0024] 4. Place the battery module on the welding table, and use the welding device to weld the conductive sheet at the holes on the bottom plate and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com