A plastic bottle injection mold opening and picking manipulator

A technology for plastic bottles and manipulators, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of damage to the screw thread structure of the bottle mouth, difficulty in gripping, and high frequency of grabbing, and can improve the speed of cooling and the stability of grabbing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

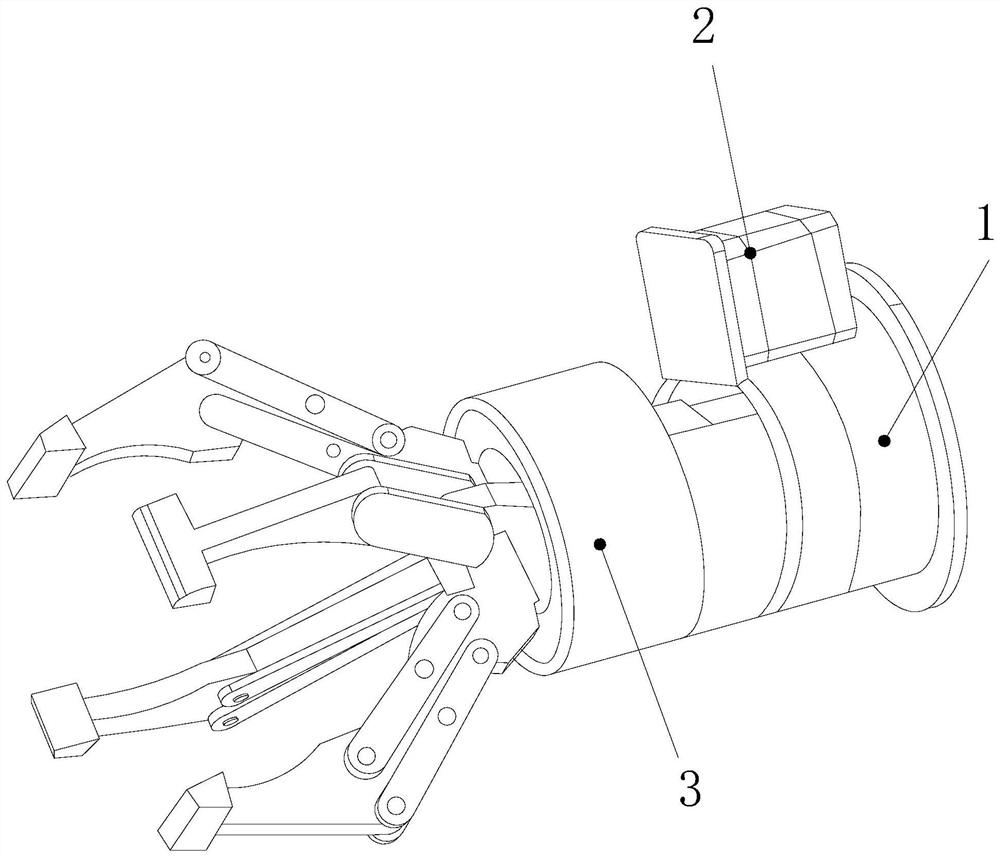

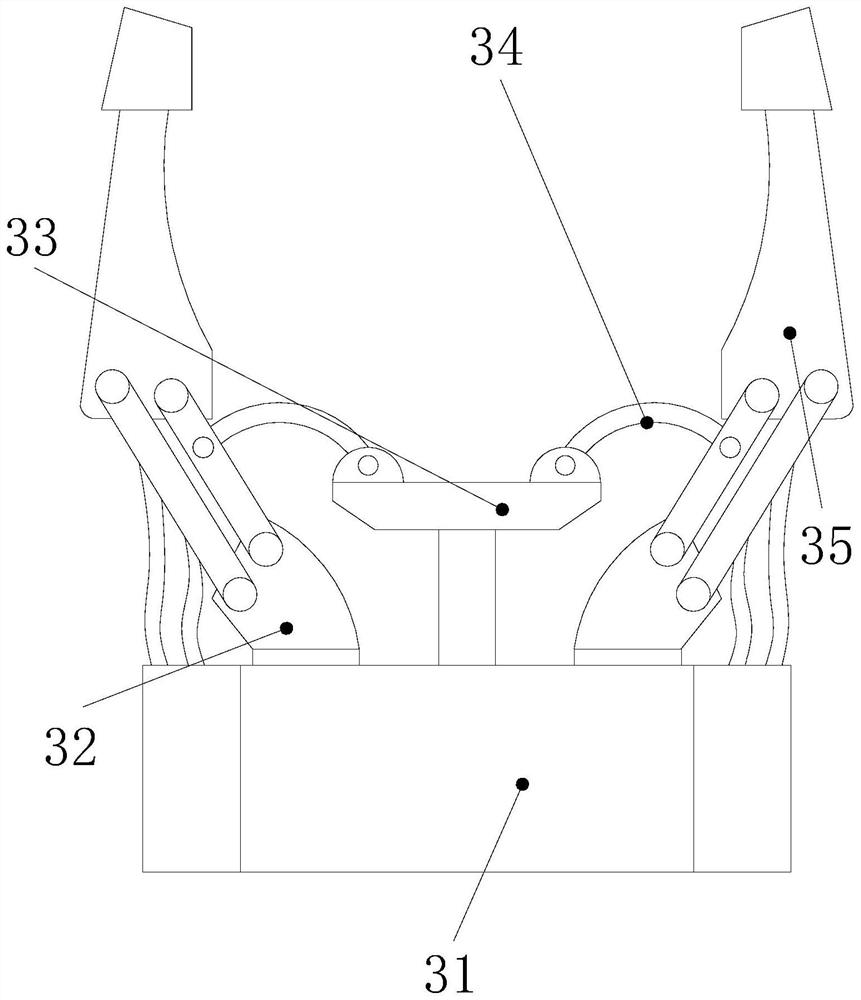

[0024] Append figure 1 Attachment Figure 4 Looking:

[0025] The present invention provides a plastic bottle injection mold pick manipulator, which comprises a fixed base structure 1, the adjustment motor 2, the crawler frame 3, the fixed seat 1 is connected to the rear side of Fixed gripping frame 3, the adjustment motor 1 and holder 2 side screwing, the gripping frame 3 includes a cooling means 31, a curved seat 32, the push rod 33, arc rod 34, the gripping head 35, the cooling device 31 and the front end of the fixing base 1 embeded connected to a curved seat 32 and side weld 31 connecting the cooling device, the cooling device 31 and the push rod 33 inside the central engagement activities, the rod 34 is connected between the upper end of the arc 35 and the push rod 33 in the middle of the gripping head the gripping head 35 with a curved seat 32 connected to the upper end of riveting, the gripping head 35 four in number, and the push rod 33 to form an annular distribution cent...

Embodiment 2

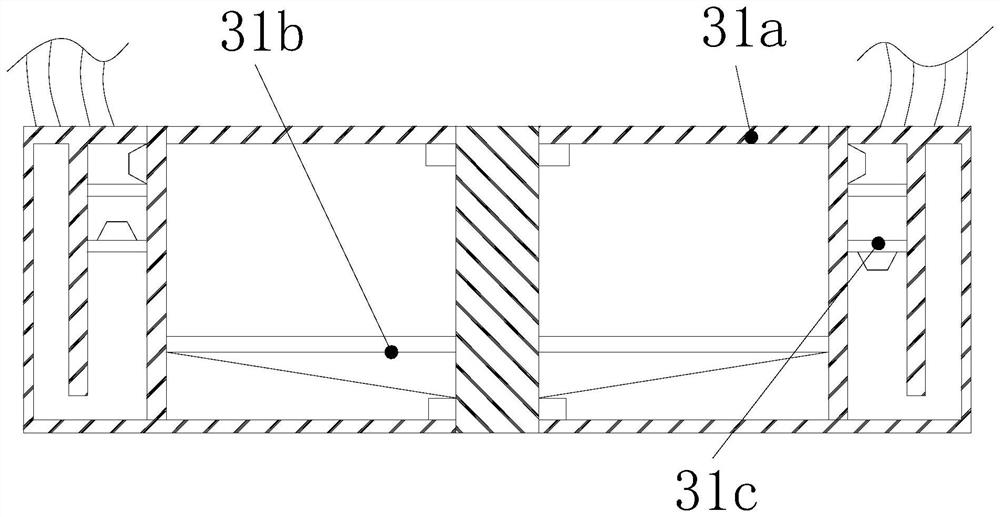

[0031] Append Figure 5 Attachment Figure 7 Looking:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com