Silicon/carbon-based composite immobilized enzyme environment-friendly material and preparation method thereof

A technology of immobilized enzymes and environmentally friendly materials, applied in the field of environmental biology, can solve the problems of high cost, unsatisfactory treatment effect, low enzyme utilization rate, etc., and achieve the effect of low cost, wide ambient temperature and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

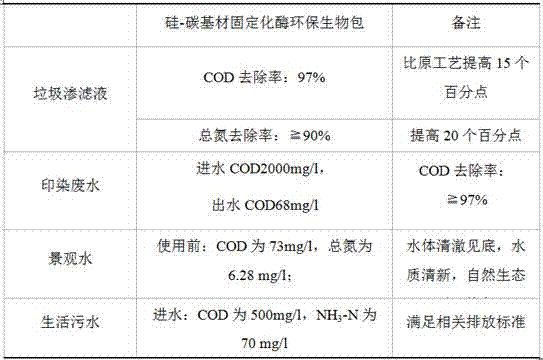

Embodiment 1

[0042] According to the pollution characteristics of landfill leachate, a silicon / carbon-based composite immobilized enzyme environmental protection material was prepared. The specific steps are as follows:

[0043] 1) Preparation of immobilized enzyme granules:

[0044] a) Activation treatment of silicon / carbon-based support: Soak the pretreated activated carbon and diatomaceous earth in 1.5wt% glutaraldehyde solution, activate for 4 hours, wash with deionized water, air dry naturally, and set aside;

[0045] b) Preparation of nano-silicon / carbon-based support: Dry Al2O3 and activated silicon / carbon-based support at 75°C for 2h, then raise the temperature to 350°C and keep it warm for 0.7h to obtain a particle size of 3- 10 mm nano-silicon / carbon-based support; in the nano-silicon / carbon-based support, nanomaterials account for 5wt%, and silicon / carbon-based supports account for 95wt%;

[0046] c) Preparation of biological enzyme liquid: select 10 parts of cellulase, 7 parts...

Embodiment 2

[0054] According to the pollution characteristics of printing and dyeing wastewater, a silicon / carbon-based composite immobilized enzyme environmental protection material was prepared. The specific steps are as follows:

[0055] 1) Preparation of immobilized enzyme granules:

[0056] a) Activation treatment of silicon / carbon-based support: Soak the pretreated diatomite and activated carbon in 0.8wt% glutaraldehyde solution, activate for 3 hours, wash with deionized water, drain and set aside;

[0057] b) Preparation of nano-silicon / carbon-based support: Dry Al2O3 and activated silicon / carbon-based support at 100°C for 1 hour, then raise the temperature to 300°C and keep it warm for 1 hour to obtain a particle size of 3-10 mm nano-silicon / carbon-based carrier; in the nano-silicon / carbon-based carrier, nanomaterials account for 0.5wt%, and silicon / carbon-based carriers account for 99.5wt%;

[0058] c) Preparation of biological enzyme liquid: select 9 parts of cellulase, 3 parts...

Embodiment 3

[0066] According to the pollution characteristics of landscape water, a silicon / carbon-based composite immobilized enzyme environmental protection material was prepared. The specific steps are as follows:

[0067] 1) Preparation of immobilized enzyme granules:

[0068] a) Activation treatment of silicon / carbon-based support: Soak the pretreated diatomite and activated carbon (the ratio of diatomite to activated carbon is 1:10) in 3wt% glutaraldehyde solution, activate for 3h, and use After washing with ion-free water, air dry naturally and set aside;

[0069] b) Preparation of nano-silicon / carbon-based support: Dry Al2O3 and activated silicon / carbon-based support at 50°C for 2h, then raise the temperature to 400°C and keep it warm for 0.5h to obtain a particle size of 3- 10 mm nano-silicon / carbon-based carrier; in the nano-silicon / carbon-based carrier, nanomaterials account for 10wt%, and silicon / carbon-based carriers account for 90wt%;

[0070] c) Preparation of biological ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com