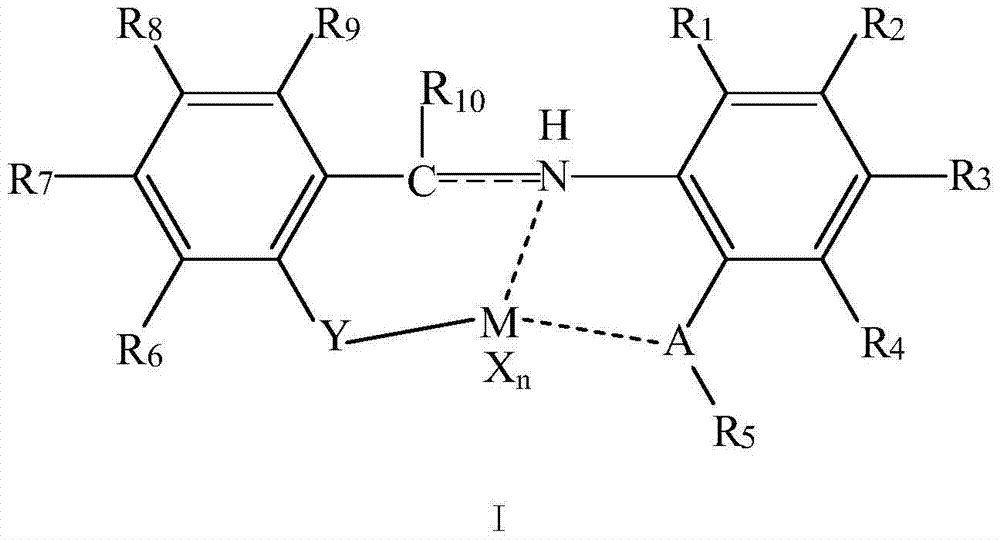

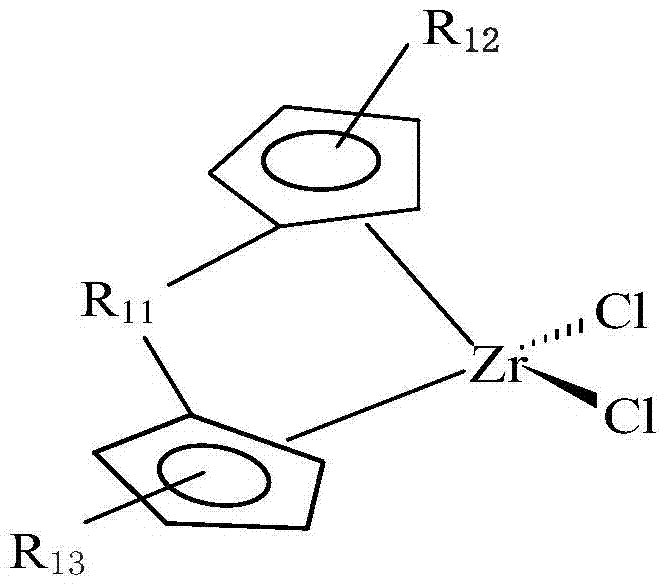

Three-activity-center composite catalyst, and method for preparing cycloolefin copolymer by using three-activity-center composite catalyst

A cycloolefin copolymer and composite catalyst technology, which is applied in the field of three active center composite catalysts, can solve the problems of poor processability and low polymerization activity of non-metallocene catalysts, and achieve the best elongation at break and impact strength, good processability, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 1L tank reactor, dissolve 0.15mol of refined norbornene in 500ml of refined toluene to make a solution, add this solution to the reactor that has been flushed with nitrogen in advance, and punch ethylene (0.1MPa) several times to make the solution Saturated with ethylene, under the conditions of 60°C, 0.1MPa and stirring, add 18ml of toluene solution with a concentration of 1.72mol / L methylaluminoxane (MAO), 10μmol of salicylidene 2-mercaptoaniline titanium trichloride , 10 μmol of racemic-vinyl (diindenyl) zirconium dichloride and 10 μmol of dichlorozirconocene three-site composite catalyst, the polymerization process is supplemented by metering ethylene, and the control pressure is 0.1 MPa.

[0037] After reacting for 0.2h, stop the reaction, pour the reaction solution into ethanol (composed of 150mL hydrochloric acid and 1000mL ethanol) containing 15% (v / v%) hydrochloric acid, filter after precipitation, filter cake after washing with ethanol (300ml), and dry (d...

Embodiment 2

[0039] What used in this embodiment is a 1L tank reactor. Dissolve 0.15mol of refined norbornene in 500ml of refined toluene to make a solution, add the solution to a reactor that has been flushed with nitrogen, and punch ethylene (0.1MPa) several times to make the solution saturated with ethylene, Under the condition of 0.1MPa and stirring, add 15ml of toluene solution with a concentration of 1.72mol / L methylaluminoxane (MAO), 2μmol 3,5-di-tert-butyl salicyl 2-propylthioaniline trichloro Titanium oxide, 18 μmol racemic-vinyl (diindenyl) zirconium dichloride and 5 μmol di-n-butyl dichlorozirconocene composite catalyst with three active sites. During the polymerization process, ethylene is added by supplementary metering, and the control pressure is 0.1MPa .

[0040] After reacting for 0.5h, stop the reaction, pour the reaction solution into ethanol (composed of 150mL hydrochloric acid and 1000mL ethanol) containing 15% (v / v%) hydrochloric acid, filter after precipitation, fil...

Embodiment 3

[0042] What used in this embodiment is a 1L tank reactor. Dissolve 0.15mol of refined norbornene in 500ml of refined toluene to form a solution, add the solution to a reactor that has been flushed with nitrogen, and punch ethylene (0.1MPa) several times to make the solution saturated with ethylene. Under the condition of 0.1MPa and stirring, 1.15mmol of triethylaluminum, 21ml of toluene solution with a concentration of 1.72mol / L methylalumoxane, 18μmol of 3,5-di-tert-butylsalicyl 2-propylthio Aniline titanium trichloride, 2 μmol racemic-vinyl (diindenyl) zirconium dichloride and 15 μmol di-n-butyl dichlorozirconocene three-site composite catalyst, the polymerization process is controlled by supplementary metering of ethylene. The pressure is 0.1 MPa.

[0043] After reacting for 10h, stop the reaction, pour the reaction solution into ethanol containing 15% (v / v%) hydrochloric acid (composed of 150mL hydrochloric acid and 1000mL ethanol) and filter after precipitation, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com