Multifunctional composite mixed material and preparation process and application thereof

A mixed material and multi-functional technology, applied in the field of building materials, can solve the problems of increasing investment and operating costs of urban sewage, high environmental protection costs, and urban environmental pollution, achieving excellent energy efficiency, low raw material prices, and reduced investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

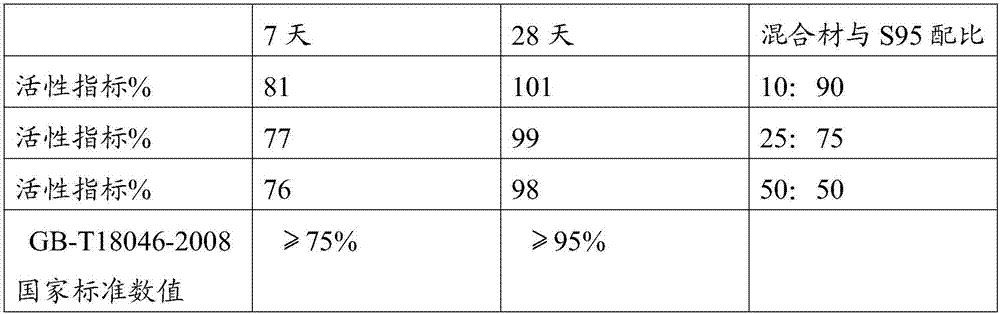

Examples

Embodiment Construction

[0032] In order to describe in detail the technical content of the present invention and the objectives and effects achieved, the following will be described in detail in conjunction with the implementation manners.

[0033] The invention discloses a multifunctional composite mixed material, which is mixed with the following raw materials in parts by weight:

[0034] 1.6-32 parts of iron and steel smelting slag from iron and steel plants, 1.6-40 parts of ferronickel slag waste from stainless steel plants, 2-48 parts of urban construction waste waste, 1.6-32 parts of marble processing waste, 1.6-40 parts of iron ore tailings powder, 2- 48 parts of granite tailings powder. Usually, urban construction waste mostly refers to waste sand powder such as concrete and ceramic tiles that have been sorted and crushed. The main raw material source of the invention is solid waste recycling. The source of active materials is urban construction waste, and the source of inactive materials i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com