Crankshaft-driven-piston type molecular sieve oxygen production system

A technology of crankshaft drive and oxygen production system, which is applied in the fields of oxygen preparation, specific gas purification/separation, oxygen/ozone/oxide/hydroxide, etc. down, unable to achieve miniaturization and low energy consumption and other problems, to achieve the effect of low power, simple structure and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

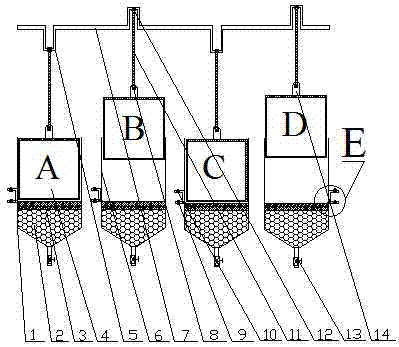

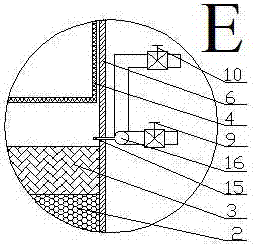

[0027] exist figure 1 In the embodiment shown in -2, the crankshaft drives the piston type molecular sieve oxygen generating system, which is composed of four sets of piston cylinder oxygen generating devices A, B, C, and D, and each set of piston cylinder oxygen generating devices includes piston 4, piston cylinder 6, Crankshaft 5, connecting rod 11, silo 1, oxygen exhaust valve 13, intake valve 9 and nitrogen exhaust valve 10; it is characterized in that: a piston cylinder 6 matching with piston cylinder 6 is installed in each set of piston cylinder oxygen making device The piston 4, the lower end of the piston cylinder 6 is the feed bin 1, the upper layer of the feed bin 1 is the filter layer 3, the lower layer of the feed bin 1 is the oxygen-producing molecular sieve 2, the funnel-shaped bottom of the feed bin 1 is connected with the oxygen exhaust valve 13, and the exhaust The oxygen valve 13 is an electric regulating valve; there is a piston head 14 in the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com