Novel manufacturing method of a large-diameter inclined tee joint

A production method and technology of oblique tees, applied in the field of new large-diameter oblique tees, can solve the problems of uneasy control of the temperature of the tee body, high cost, and quality defects of the oblique tees, and achieve easy control of the preheating temperature and production Low cost, reliable quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

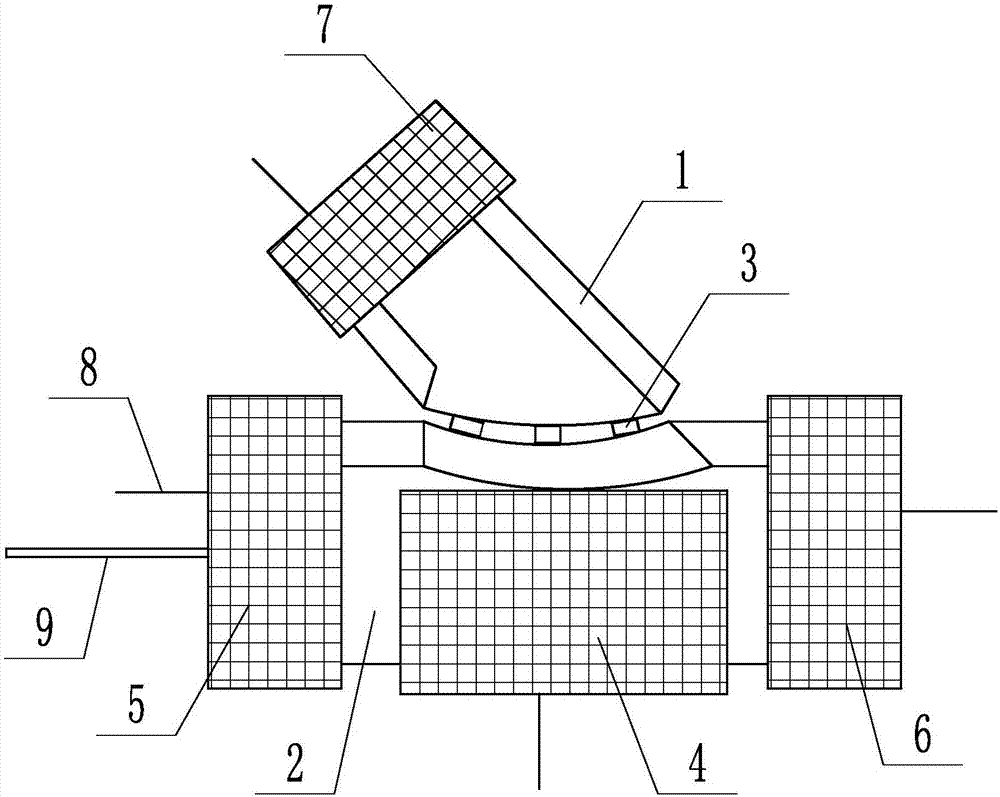

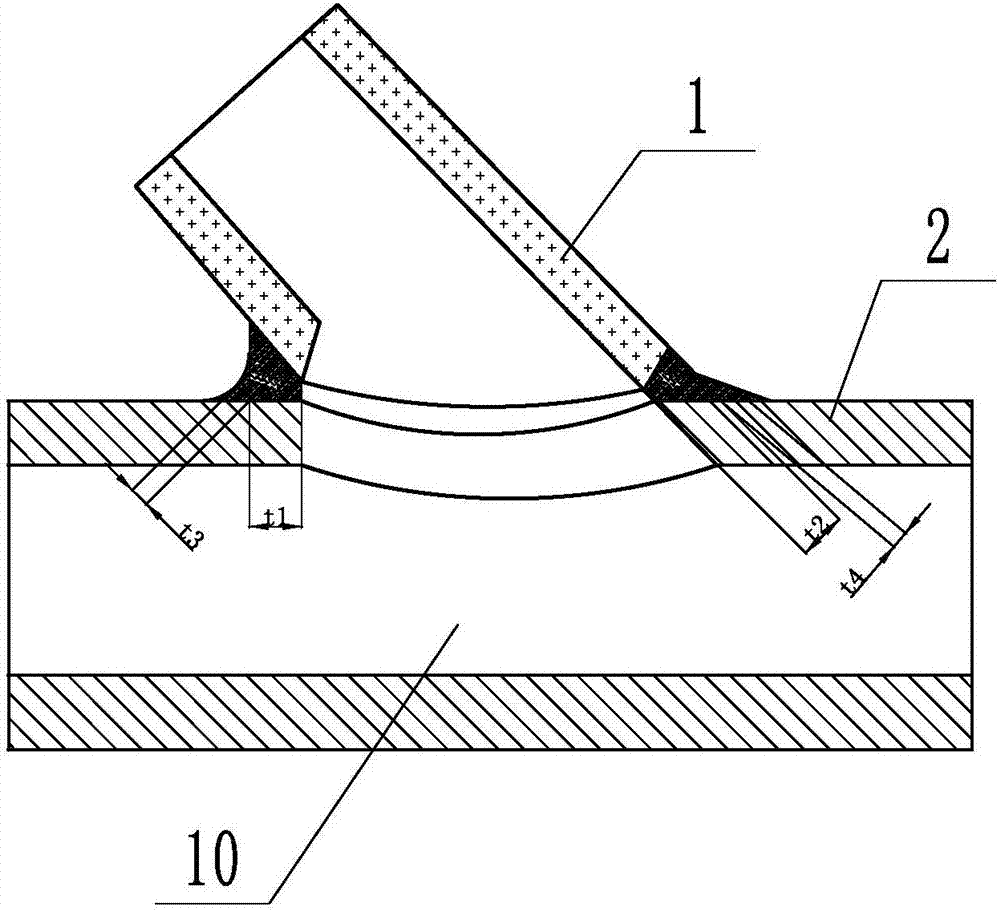

[0044] according to Figure 1 to Figure 2 As shown, a novel large-diameter oblique tee manufacturing method is characterized in that the specific steps are as follows:

[0045] A. Manufacturing and molding of oblique tee fittings

[0046] The three-way inclined branch pipe 1 and the three-way straight mother pipe 2 are cut by mechanical processing, and the pipe fittings are cut, polished and spliced into the required tee shape, and the three-way inclined branch pipe 1 and the three-way straight mother pipe 2. The jointed grooves are processed. The three-way inclined branch pipe 1 and the three-way straight main pipe 2 are made of SA-335P91 material. The processed grooves shall be based on the ability to penetrate the roots during manual argon tungsten arc welding.

[0047] B. Positioning welding of oblique tee fittings 1

[0048] The joint of the three-way inclined branch pipe 1 and the three-way straight main pipe 2 is provided with a positioning block 3, and the position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com