Hot stamping deep drawing mold of ultrahigh-strength steel box-shaped part

A technology of ultra-high-strength steel and deep-drawing dies, which is applied in household appliances, forming tools, manufacturing tools, etc., can solve the problems of no quenching function, poor quenching uniformity, and poor strength effect, so as to improve cooling efficiency and ensure uniformity and comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

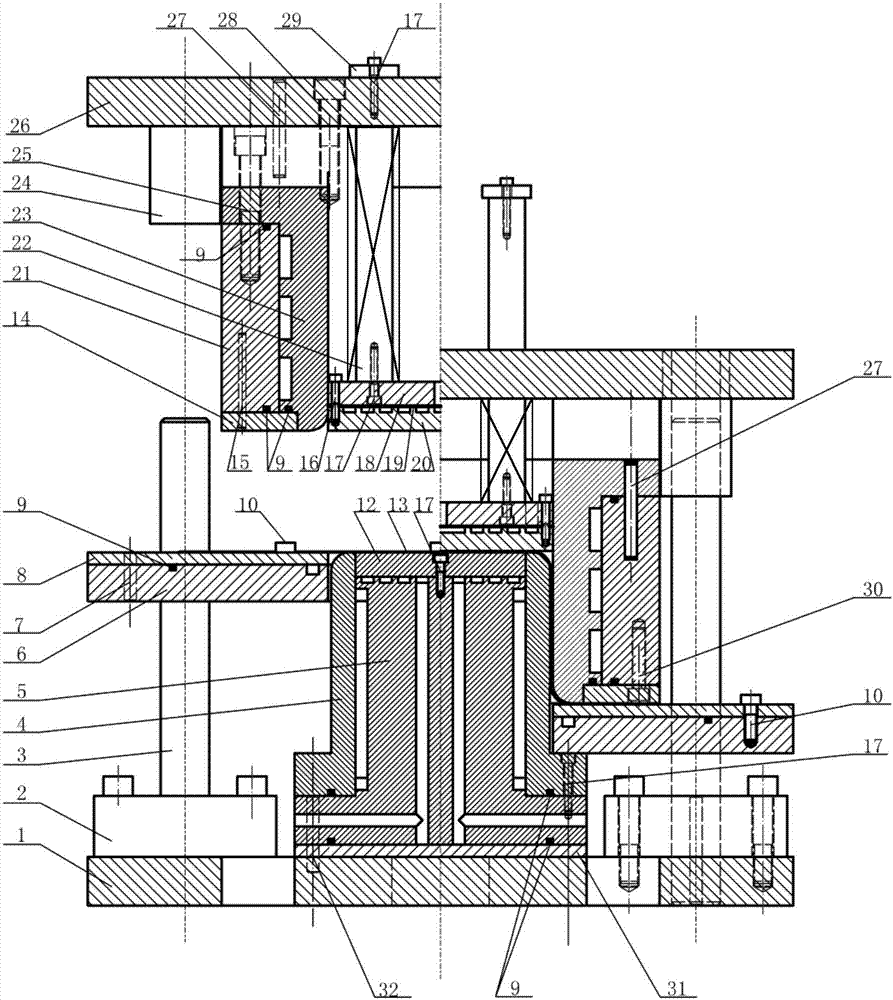

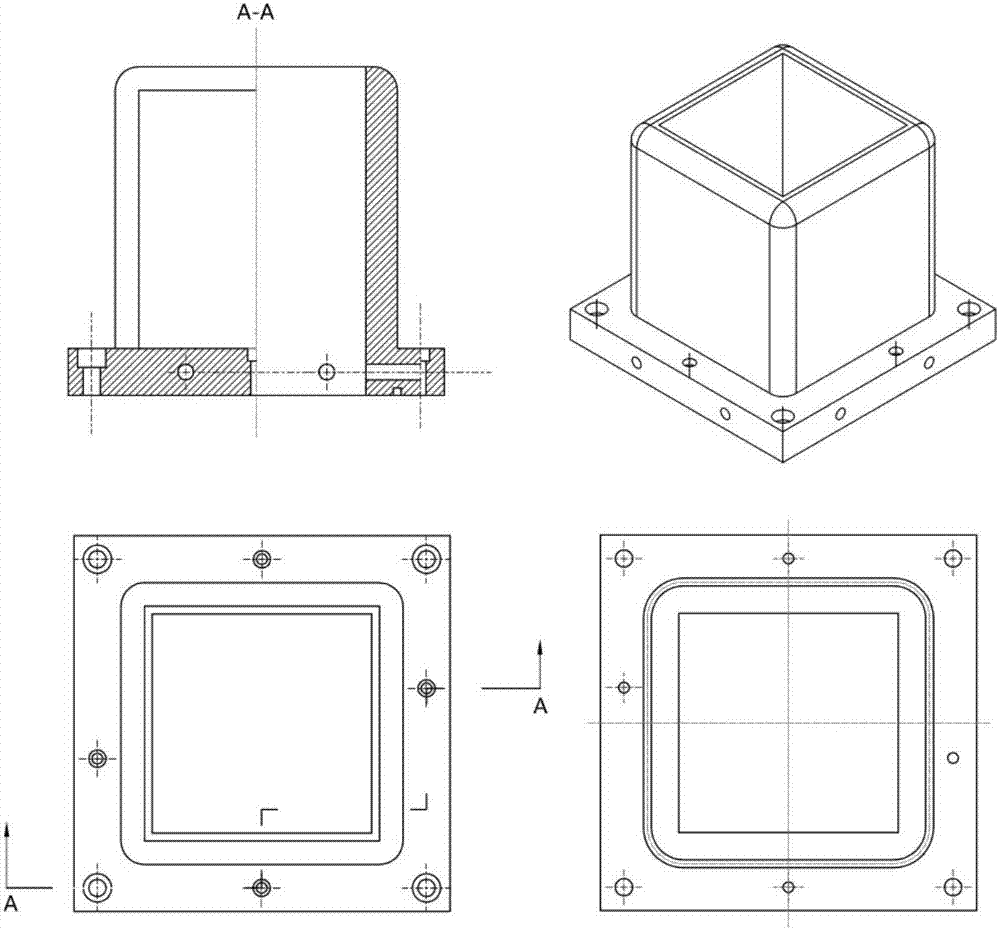

[0033] A hot stamping drawing die for ultra-high-strength steel box-shaped parts according to the present invention will be further described below in conjunction with the accompanying drawings.

[0034] Description of the composition and structure of the mold

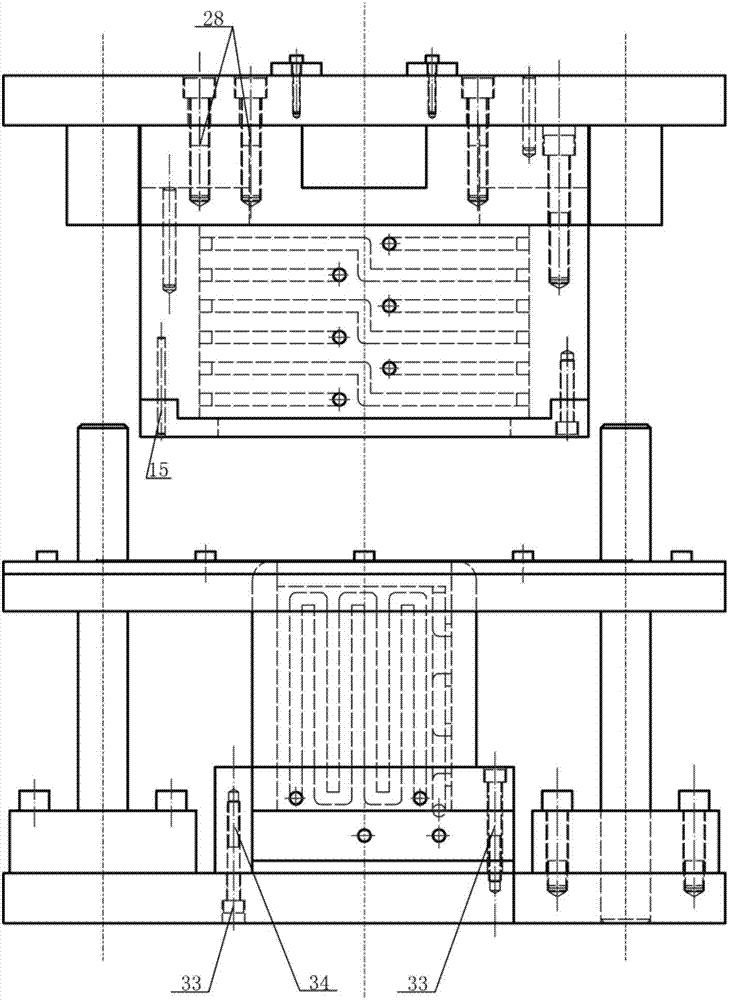

[0035] like figure 1 , 2 Shown is the overall assembly drawing of the ultra-high-strength steel box-shaped hot stamping drawing die involved in the present invention. It can be seen from the figure that the mold frame adopts a four-column formwork, which includes an upper formwork 26, a lower formwork 1, and guide posts 3, guide sleeves 24 and guide post fixing seats 2 distributed at the 4 corners of the formwork. In addition, the punch is divided into three parts: the upper cover plate 12 of the punch, the outer wall 4 of the punch, and the liner 5 of the punch, and is fixed on the upper surface of the lower template 1 together with the backing plate 31 of the punch. The specific assembly relationship is: the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com