Head-mounted slit lamp micrographic examination system

An inspection system and slit lamp technology, applied in the fields of medical science, ophthalmoscope, eye testing equipment, etc., can solve the problems of difficult semi-self-service or self-help inspection, inconvenience of carrying, operation, inconvenience of inspection and health care, etc., to achieve easy operation , The effect of facilitating daily routine inspection and simplifying equipment composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

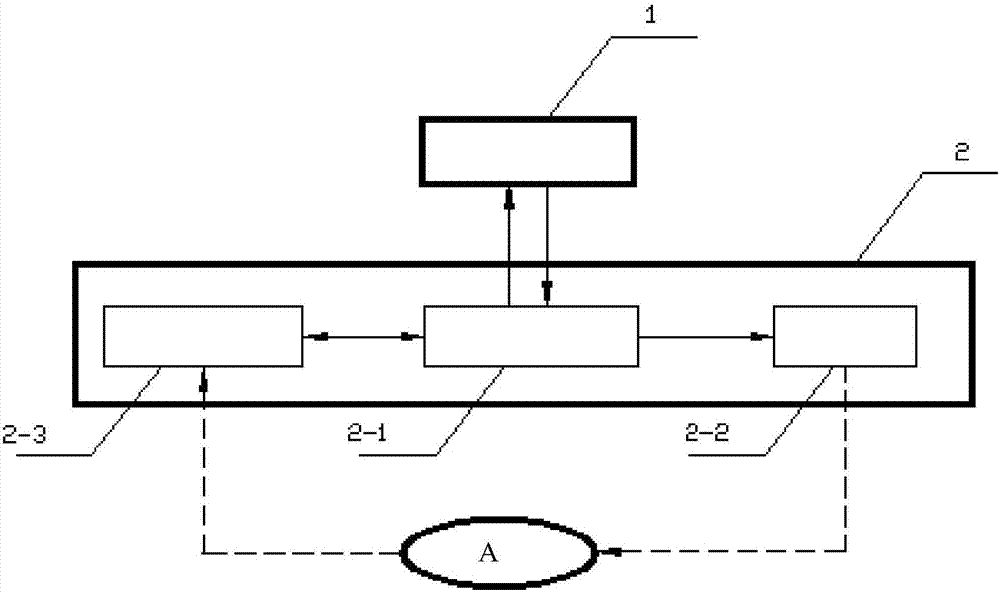

[0014] Such as figure 1 As shown, the embodiment of the present invention is provided with an inspection operation terminal 1 and a head-mounted unit 2 . The medical personnel set the detection control information (including information such as the width, color, and shape of the detection spot) and image acquisition information (magnification, etc.) required for the slit lamp microscope detection at the inspection operation terminal 1 . After the information is processed to form a patterned control command, it is sent to the head-mounted unit 2 through the communication network. After the head-mounted unit 2 receives the control command, the central control module 2-1 analyzes and processes the command to form a light source control command and an image acquisition command. , and send the light source control instruction to the projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com