Method and device for actuating a piezoelectric motor

A piezoelectric motor and control electrode technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve vibration positioning, can not prevent the motor from entering the starting torque or start Problems such as the mode and error of the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

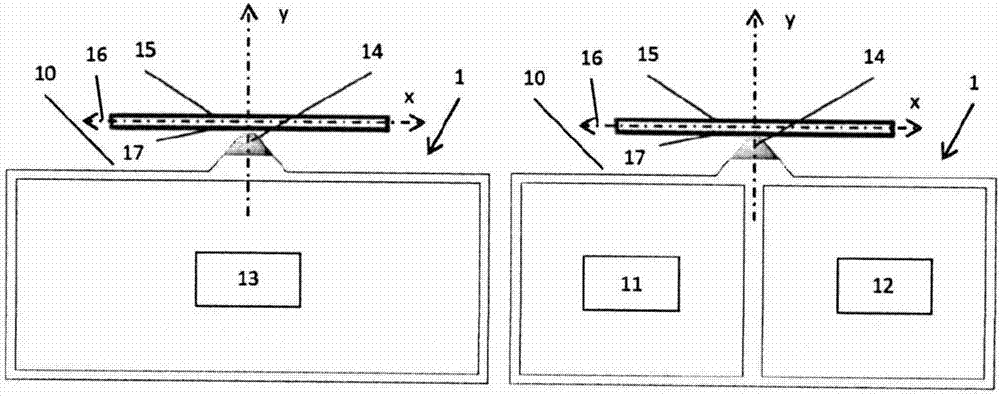

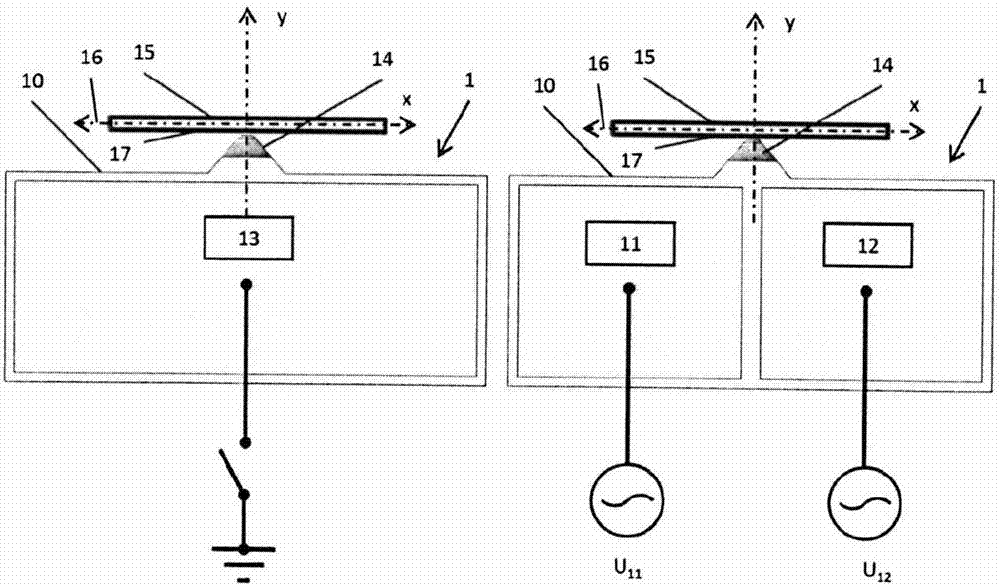

[0044] The invention relates to a method and a device for controlling a piezoelectric motor 1 with two control electrodes 11 , 12 by applying a periodic control voltage to the control electrodes 11 , 12 . In particular, it is a piezoelectric ultrasonic motor with a piezoelectric ultrasonic actuator which operates at a frequency of, for example, 156 kHz.

[0045] Refer below figure 1 and 2 A piezoelectric ultrasonic motor 1 to which the method according to the invention is applied will be described.

[0046] The piezoelectric ultrasonic motor 1 includes a total of three electrodes 11 , 12 , 13 . Two of these electrodes 11, 12 are located on one of the two planar faces of an approximately square piezoceramic element 10 (dimensions such as 25 mm x 11 mm x 4 mm) and have the same size (eg 10 mm x 10 mm) and size ( eg 100mm 2 ) of substantially square faces. The electrodes 11 , 12 mounted on a flat surface are connected via a controller (not shown) to a power source for genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com