Method for separating gaseous mixtures containing hydrocarbons

A technology for gaseous mixtures and mixtures, which is applied in the low-temperature separation of gas components, and in the field of processing associated gas or natural gas, which can solve unfavorable problems and achieve a high degree of extraction and ensure efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

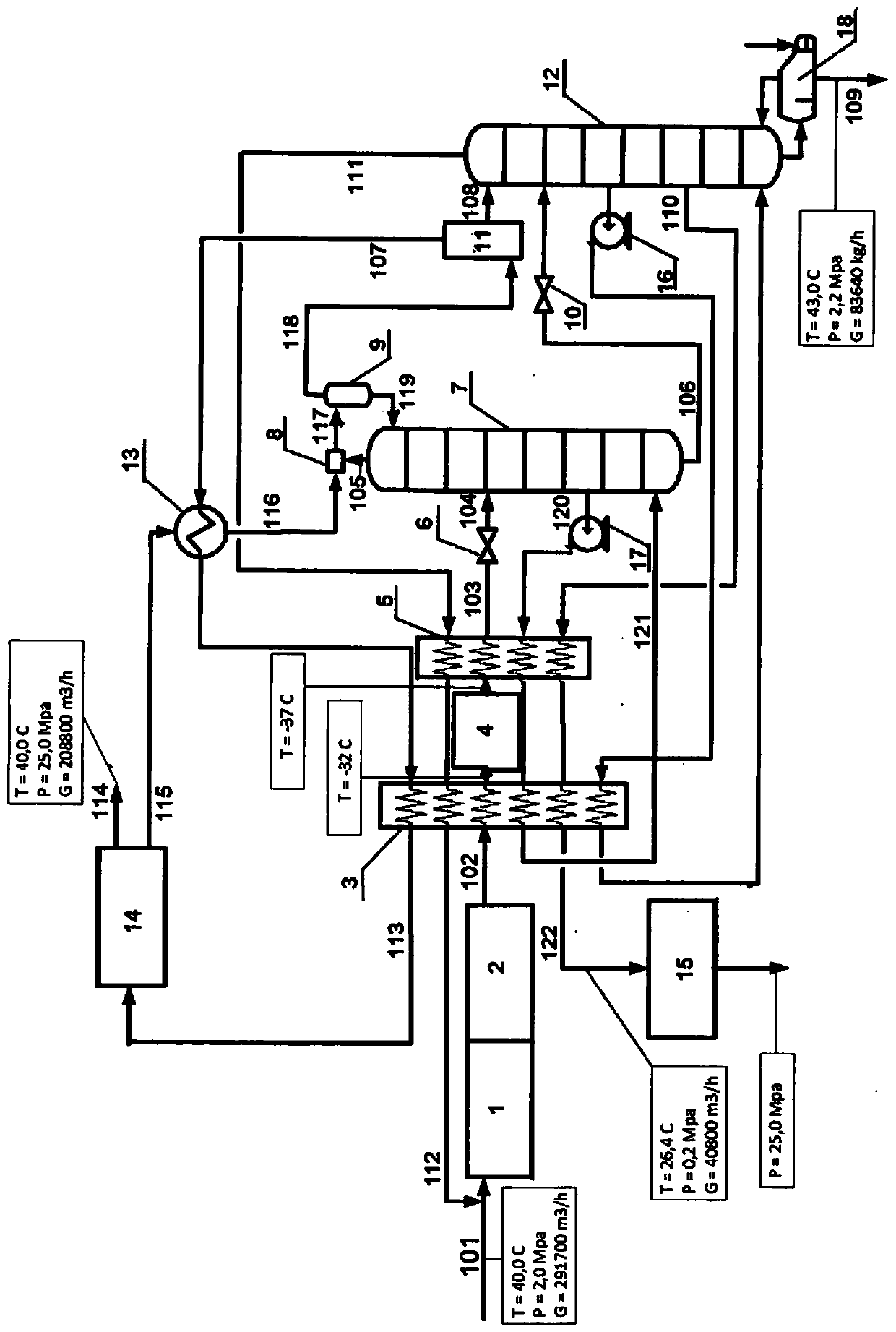

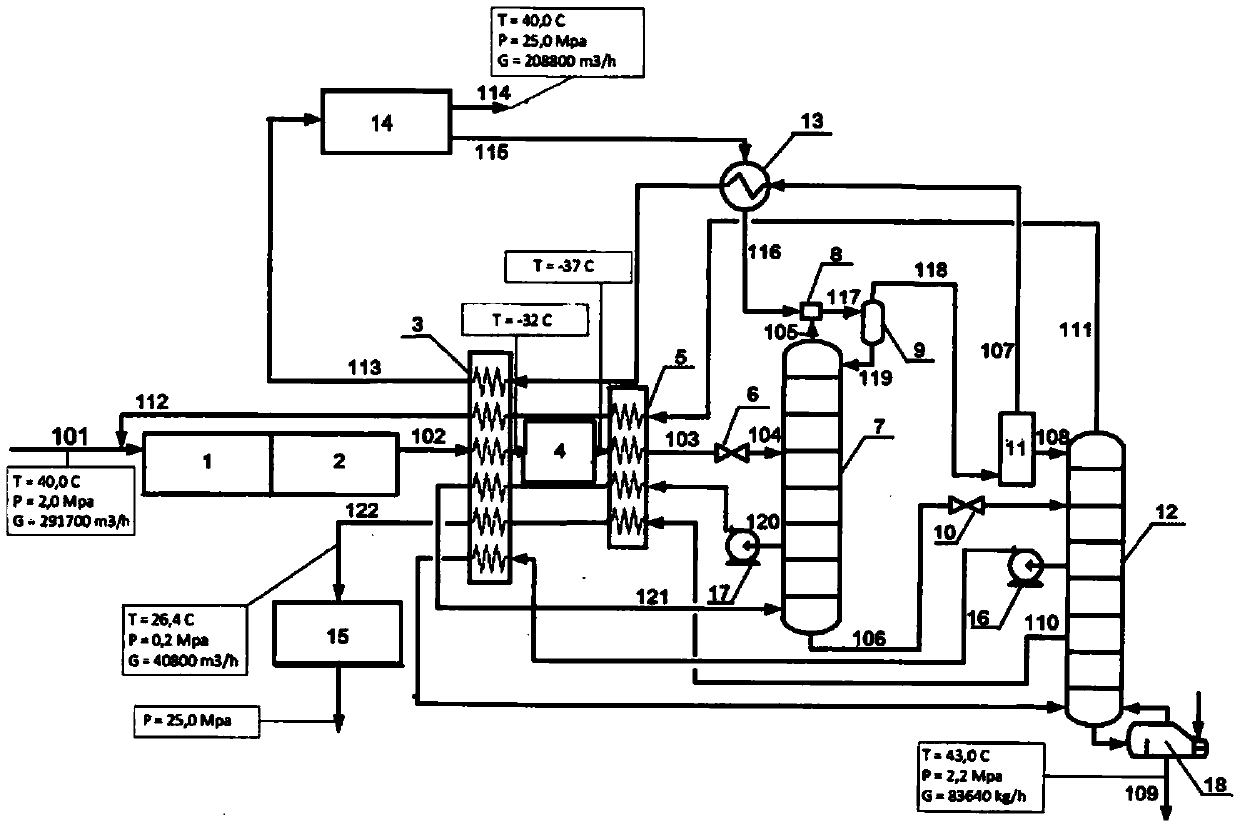

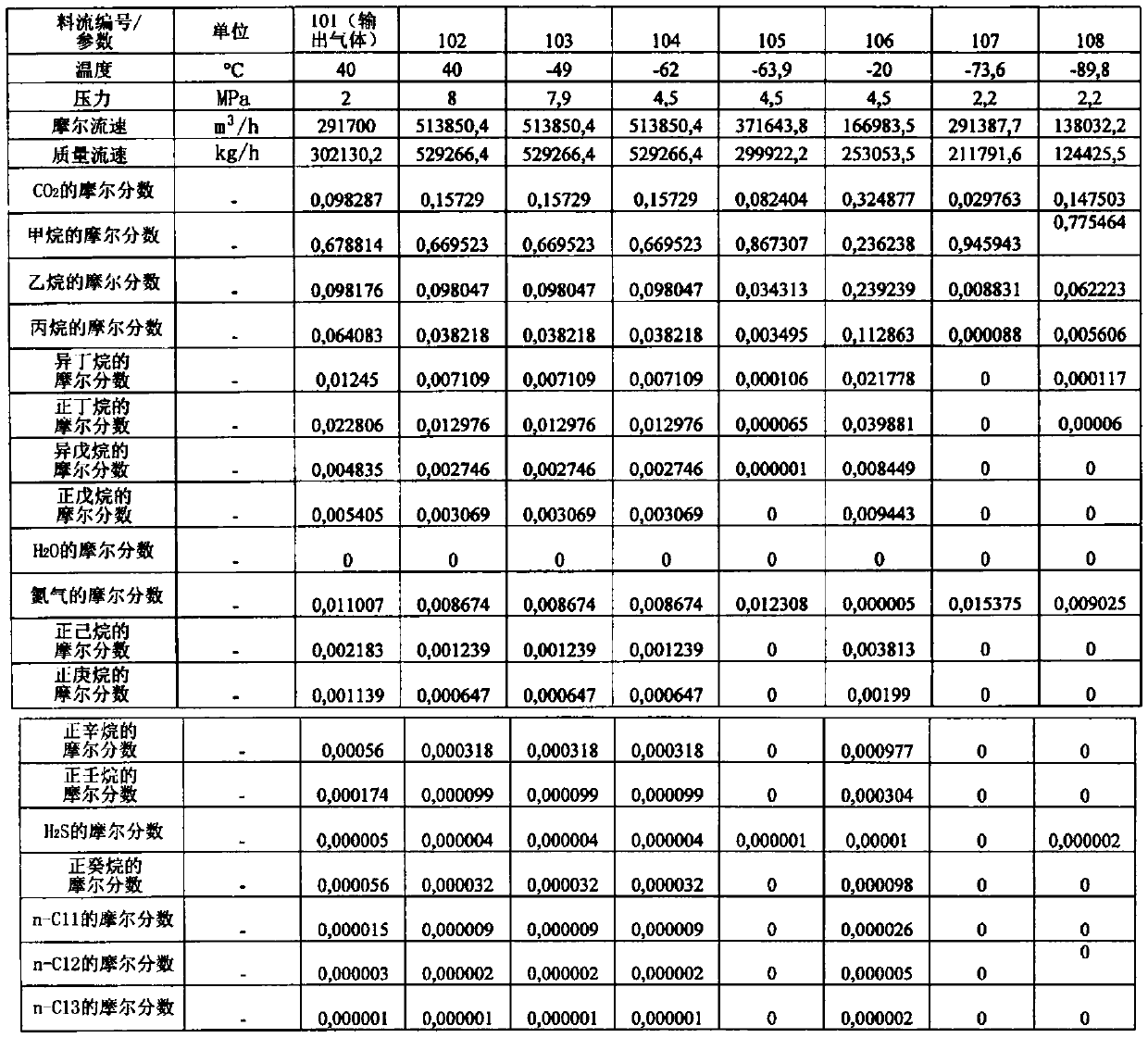

[0068] This method can be implemented as follows.

[0069]The initial gaseous mixture (101) (eg natural gas) is compressed by the first compressor (1) and dehydrated in the dehydration unit (2). The resulting mixture (102) is then cooled successively in the first heat exchanger (3), the cooler (4) and the second heat exchanger (5). The resulting stream (103) having a temperature below -40°C, preferably about -49°C, passes through the valve (6) and is expanded so as to obtain a temperature of about -62°C. The cooled stream (104) is fed to the first rectification column (7), where a first stream (105) rich in hydrocarbons and comprising dissolved CO 2 A second stream (106) of hydrocarbons in . To additionally heat the lower part of the column, a part of the liquid fraction (120) is pumped out of the column using a pump, through heat exchangers (3) and (5), and the resulting heated stream (121 ) is returned to the first rectification column (7).

[0070] After passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com