Prestressing cable, in particular for static structures

A pretensioned, static technique, applied in the direction of transmission elements or pulleys, ropes or cables, architectural, structural elements, etc., capable of solving problems of high risk of error, complex processes, inappropriate infrastructure and especially location conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

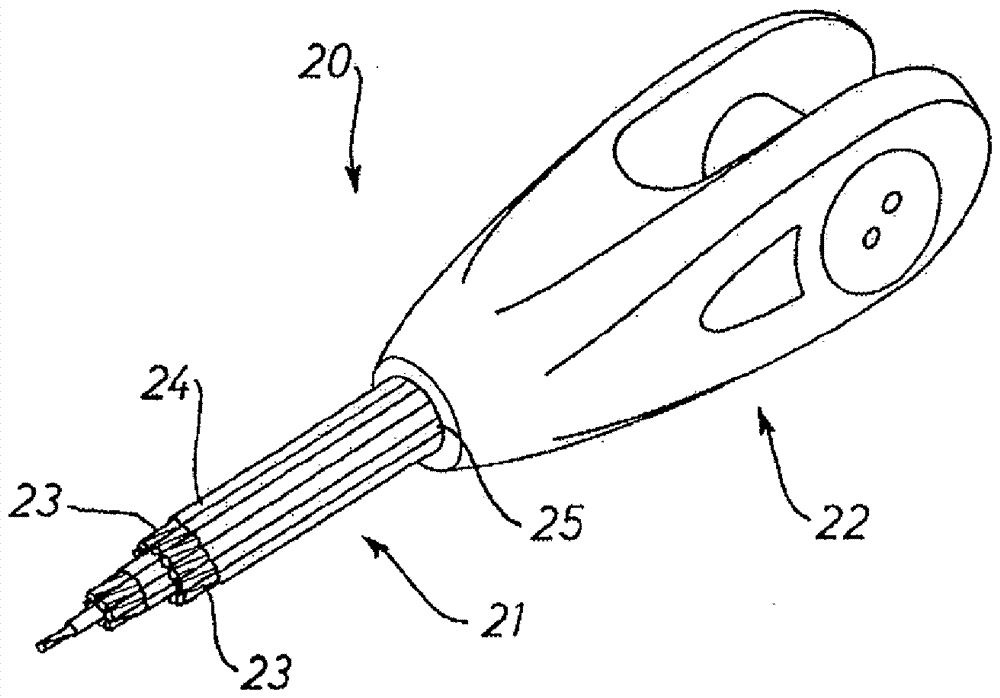

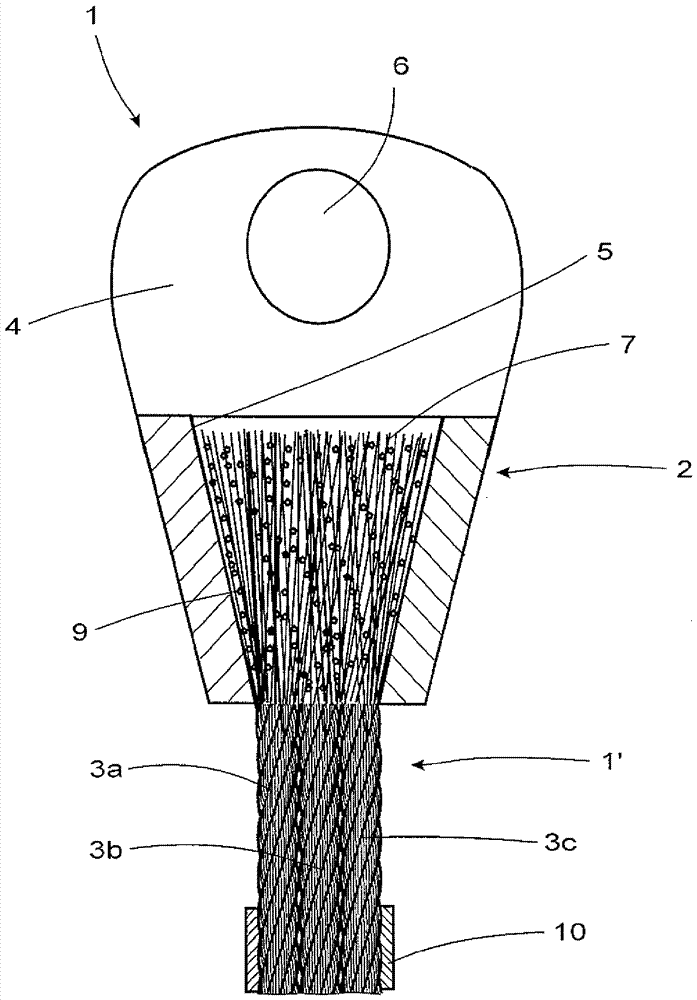

[0018] figure 1 The pretensioning cord 1 is shown in a partial view, in which the connection of the longitudinal element 1 ′ to one of the connecting elements 2 of the pretensioning cord 1 is shown. The connecting element 2 is designed as a fork-shaped sleeve 4 as shown. It can also be designed as an eyelet sleeve according to the application.

[0019] According to the invention, the longitudinal element 1 ′ consists of a plurality of strands, each of which is arranged close to one another in parallel, of which the strands 3 a , 3 b , 3 c can be seen, which are anchored in the connecting element 2 .

[0020] The connecting element 2 has a funnel-shaped opening 5 for receiving the cables 3a, 3b, 3c and a transverse circular hole 6 for receiving anchor bolts or the like.

[0021] The ropes 3 a , 3 b , 3 c consist of a plurality of strands 7 , which in each strand are stranded with one another and pressed against one another at the end sides in the region of the funnel-shaped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com