Tool system for ground milling machine and the ground milling machine comprising the tool system

A technology of milling machines and milling cutters, which is applied in the field of ground milling machines, can solve the problems of reducing material hardness or resistance, time-consuming and complicated milling cutters, etc., and achieve slow wear progress, reliable force transmission, and fast installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The same components are designated with the same reference numerals. Repeated components are not individually labeled throughout the drawings.

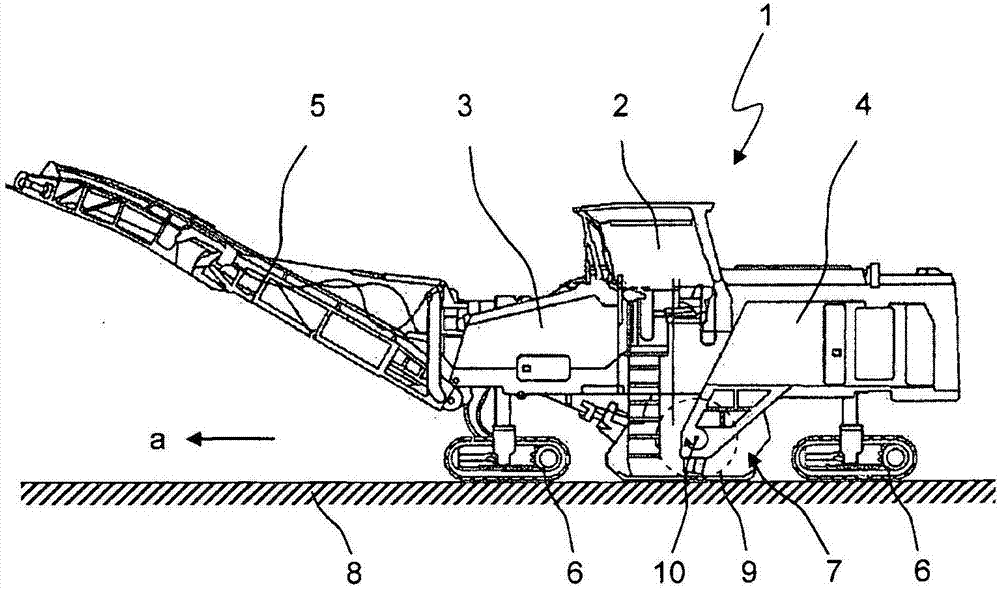

[0048] figure 1 A ground milling machine 1 is shown, here a road milling machine in the form of a cold milling machine with a central rotating part. The ground milling machine 1 comprises a cab 2 with a driver's seat and a console, a frame 3 and a drive motor 4 . The drive motor 4 , for example a diesel engine, mainly drives the traveling device 6 , the milling roller 9 and the discharge belt 5 . The milling roller 9 is mounted rotatably about a horizontal axis of rotation 10 extending transversely to the working direction a in the milling roller housing 7 . During the working mode of the ground milling machine 1 , the milling roller 9 mills the ground 8 in the working direction a. The loose milled material is transferred via the discharge belt 5 to a transport vehicle (not shown) and transported away by the transport vehic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com