Fluid flow assembly and fuel cell stack containing the fluid flow assembly

A fuel cell stack and fluid flow technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of difficult oxygen discharge, difficult discharge, and blockage of oxygen circulation channels, so as to achieve smooth and stable flow process and stable power generation performance. , the effect of reducing the gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

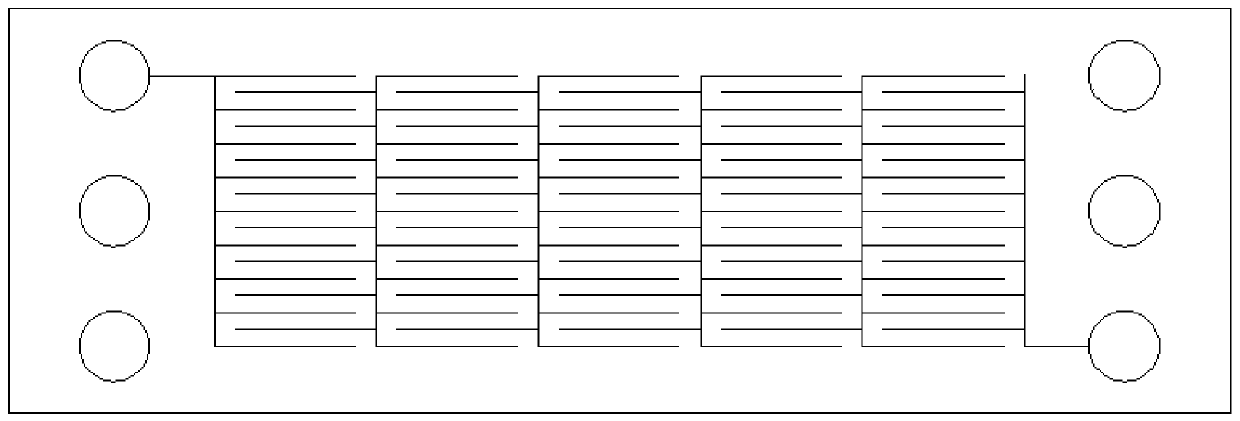

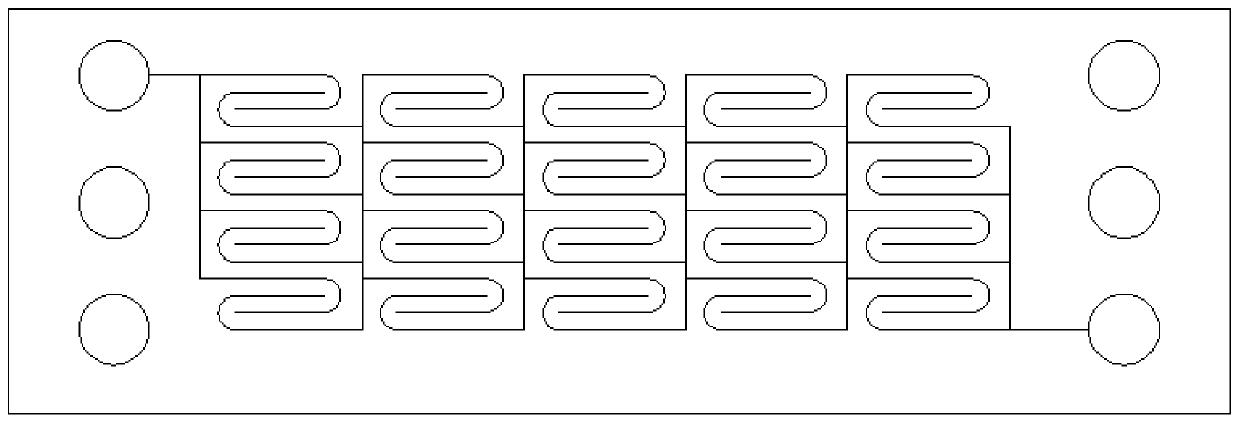

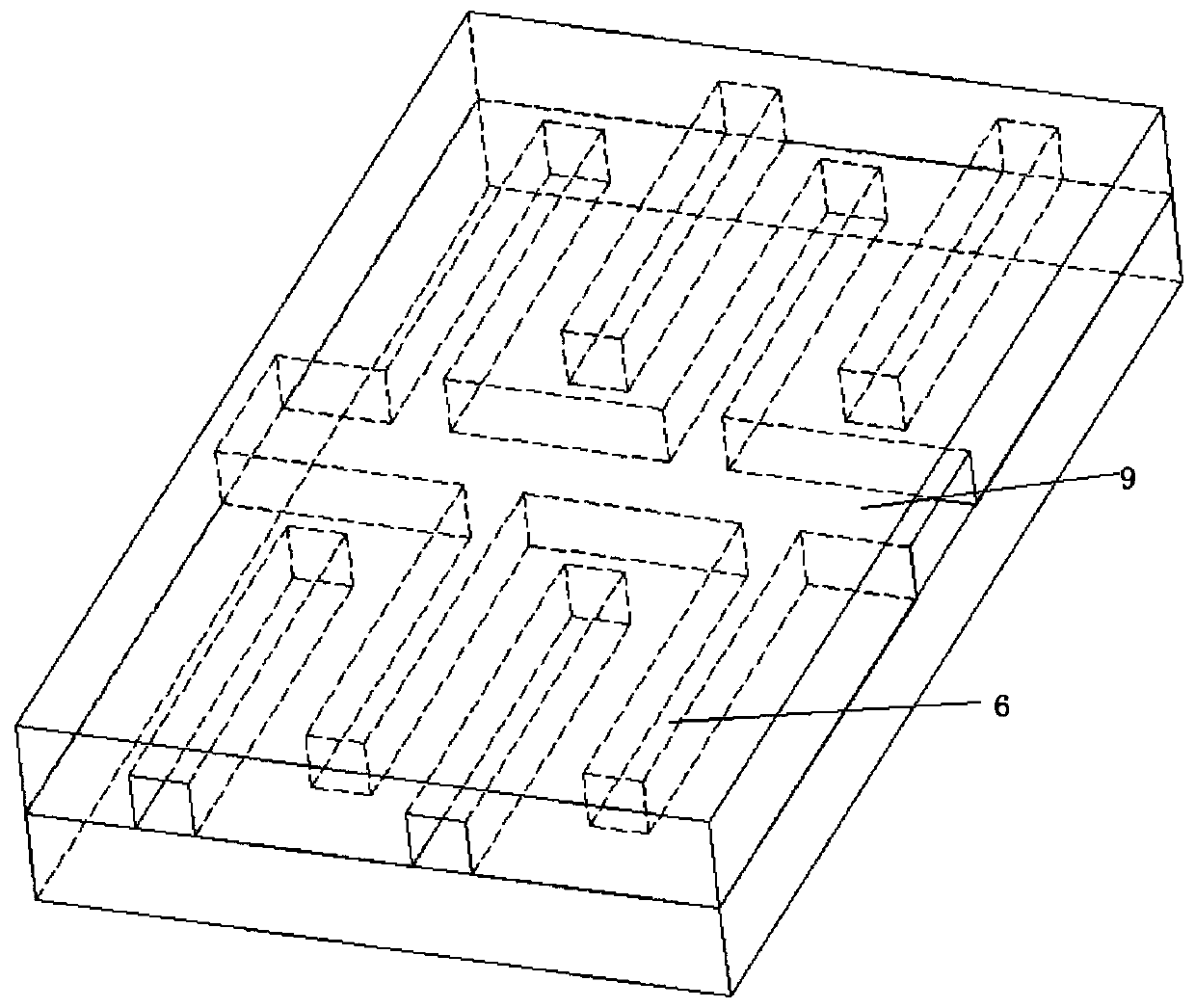

[0034] The fluid flow assembly includes a distribution deflector for draining fluid and a fluid flow layer as a fluid main channel, and the distribution deflector is fixedly connected with the fluid flow layer to form a fluid flow assembly. The distribution deflector is provided with a fluid distribution groove and a drainage groove, and the fluid flow assembly in this embodiment uses the fluid flow layer as the main channel of the fluid, and cooperates with the fluid distribution groove 6 and the drainage groove 9 on the distribution deflector , to facilitate the discharge of stagnant fluid. The fluid flow assembly 12 is suitable for single function fuel cells or electrolyzers or reversible fuel cells. A simple schematic diagram of the combination of the fluid flow assembly 12 and the membrane electrode 11 is shown in Figure 5 As shown, the fluid enters and exits through the inlet and outlet of the distribution deflector. The membrane electrode is composed of a catalytic l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com