Self-grouting backpressure valve

A self-grouting and mud technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of blocking water holes, reducing the strength of valve body, and high grouting cost, so as to prevent blowout and well kick , The effect of ensuring the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

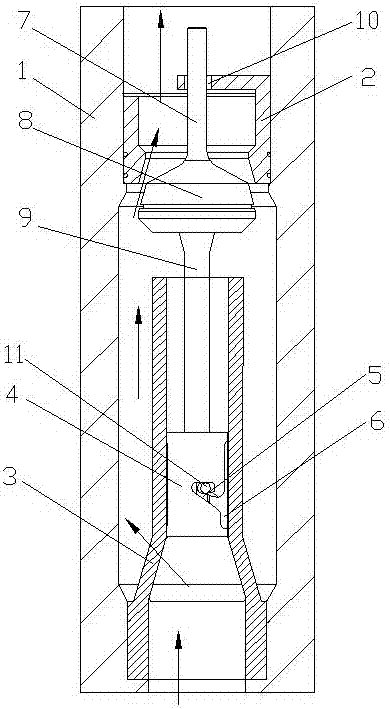

[0042] see figure 1 , a self-grouting back pressure valve, including a valve body 1, a valve core set in the valve body 1, a valve seat 2 and a support seat 3, the support seat 3 is located below the valve seat 2, and the support seat 3 is set There is a sliding sleeve 4, and the sliding sleeve 4 is provided with a lateral hanging groove 5 and a vertical sliding groove 6, the lateral hanging groove 5 and the vertical sliding groove 6 communicate, and the valve core includes an upper valve stem connected together 7. Tapered block 8 and lower valve stem 9, the valve seat 2 is provided with a guide hole 10 for the axial movement of the upper valve stem 7, the upper valve stem 7 runs through the guide hole 10, and the lower valve stem 9 is provided with a hanger Pin 11, the hanger pin 11 is hooked on the sliding sleeve 4.

[0043] This embodiment is the most basic implementation, including a valve body, a valve core arranged in the valve body, a valve seat and a support seat, the...

Embodiment 2

[0045] see figure 2 , a self-grouting back pressure valve, including a valve body 1, a valve core set in the valve body 1, a valve seat 2 and a support seat 3, the support seat 3 is located below the valve seat 2, and the support seat 3 is set There is a sliding sleeve 4, and the sliding sleeve 4 is provided with a lateral hanging groove 5 and a vertical sliding groove 6, the lateral hanging groove 5 and the vertical sliding groove 6 communicate, and the valve core includes an upper valve stem connected together 7. Tapered block 8 and lower valve stem 9, the valve seat 2 is provided with a guide hole 10 for the axial movement of the upper valve stem 7, the upper valve stem 7 runs through the guide hole 10, and the lower valve stem 9 is provided with a hanger Pin 11, the hanger pin 11 is hooked on the sliding sleeve 4.

[0046] A return spring 12 is sleeved on the lower valve stem 9 , one end of the return spring 12 is in contact with the tapered block 8 , and the other end i...

Embodiment 3

[0049] see image 3 , a self-grouting back pressure valve, including a valve body 1, a valve core set in the valve body 1, a valve seat 2 and a support seat 3, the support seat 3 is located below the valve seat 2, and the support seat 3 is set There is a sliding sleeve 4, and the sliding sleeve 4 is provided with a lateral hanging groove 5 and a vertical sliding groove 6, the lateral hanging groove 5 and the vertical sliding groove 6 communicate, and the valve core includes an upper valve stem connected together 7. Tapered block 8 and lower valve stem 9, the valve seat 2 is provided with a guide hole 10 for the axial movement of the upper valve stem 7, the upper valve stem 7 runs through the guide hole 10, and the lower valve stem 9 is provided with a hanger Pin 11, the hanger pin 11 is hooked on the sliding sleeve 4.

[0050] The supporting base 3 is provided with an annular baffle 13, the center of the annular baffle 13 has a through hole, the lower valve stem 9 runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com