Multi-layer and large-span assembly-type orthogonal and vertical assembly-type concrete space grid box structure and manufacturing method

A technology of orthogonal placement and space grid, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of incomplete prefabrication of the structural system, poor lateral stiffness of the structure, and failure to meet seismic codes, etc. Achieve the effect of improving the bending and shearing rigidity of the structure, reducing the engineering cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

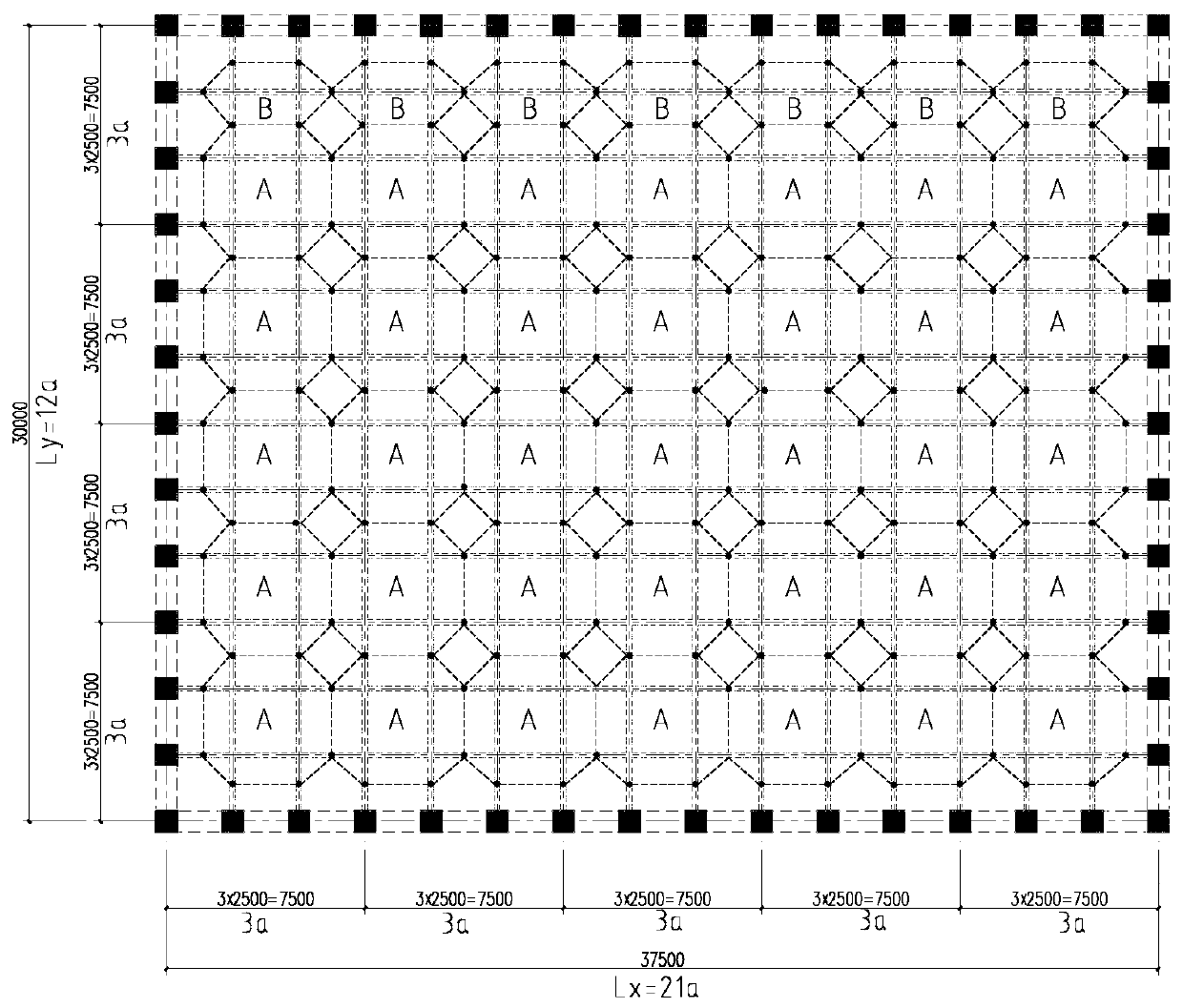

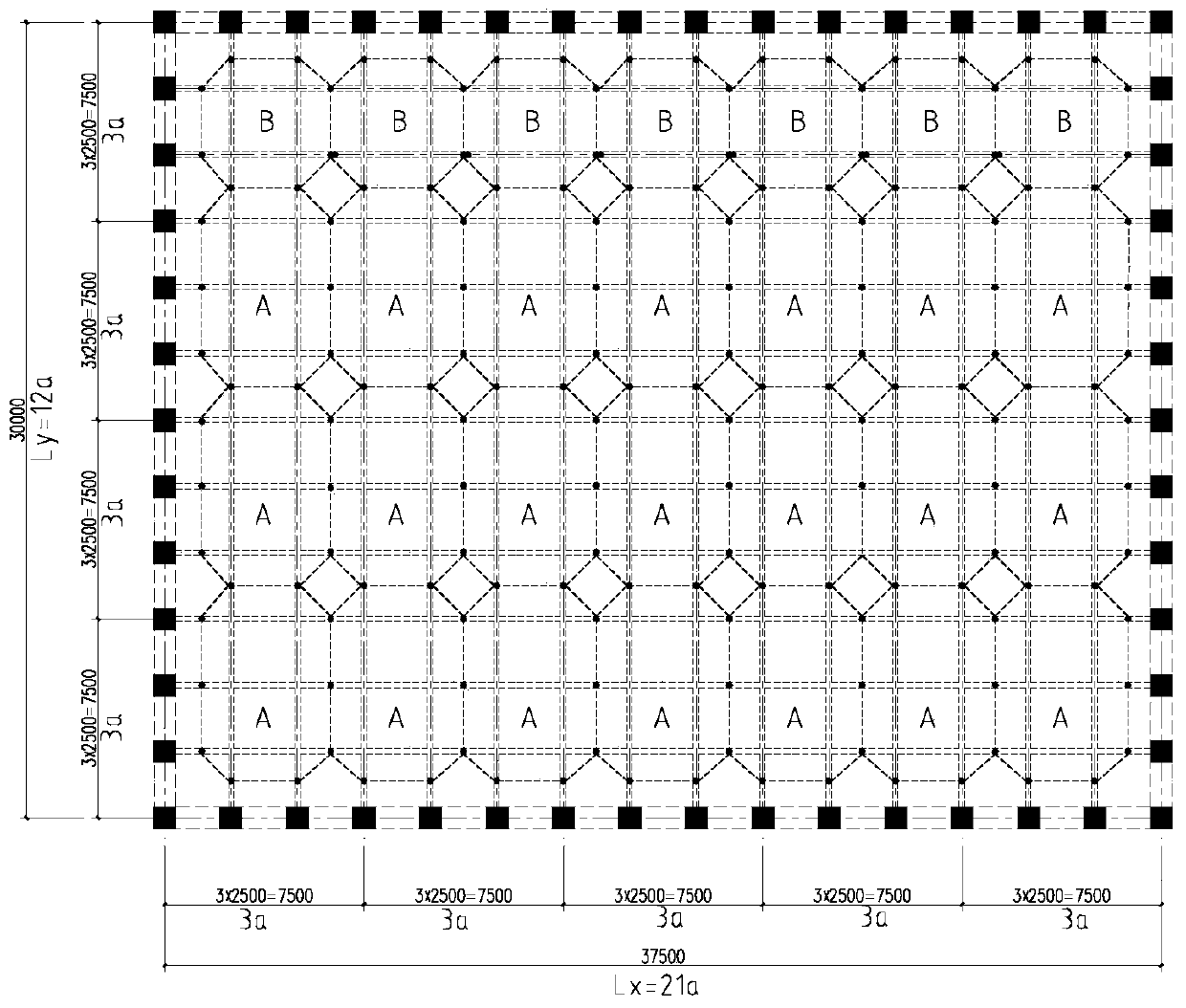

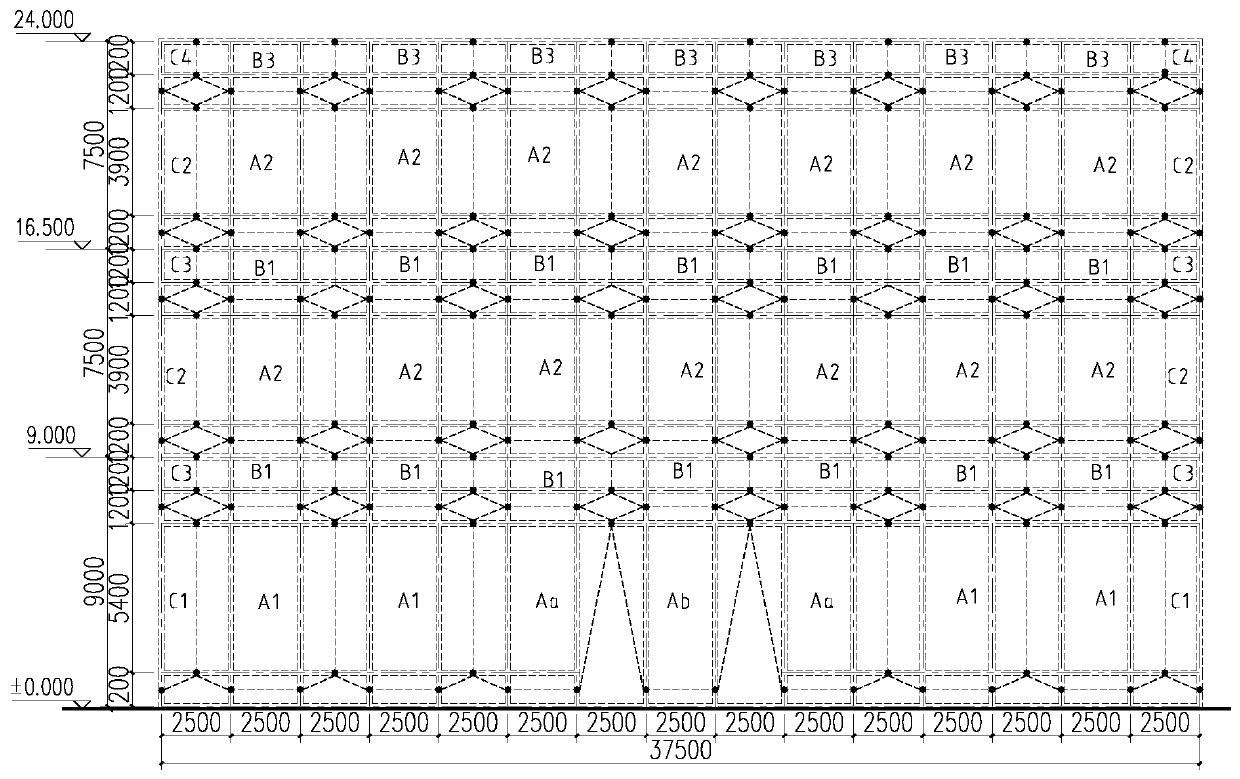

[0027] The present invention is implemented for the three-story floor, the specific span Ly=30m, the length Lx=37.5m, the aspect ratio Lx / Ly=37.5 / 30=1.25 is less than 1.5, it is suitable to adopt the scheme of the present invention, the area of each floor is 1125m2, when When Lx / Ly=1, it is the most ideal situation of this scheme.

[0028] The multi-layer large-span assembled orthogonally placed assembled concrete space grid box-type structure of the present invention has three layers. It is 7.5m.

[0029] The multi-storey large-span assembled concrete space grid box structure, including the use of multi-storey large-span assembled concrete orthogonally placed hollow floor as the floor structure, and the use of orthogonally placed concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com