Electromagnetic energy rapid sterilization sludge dehumidifying and drying system

A technology of electromagnetic energy and sludge, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of low sludge drying and drying efficiency and adverse effects on the surrounding environment , complex structure and other problems, to achieve the effect of improving drying effect, low maintenance cost, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

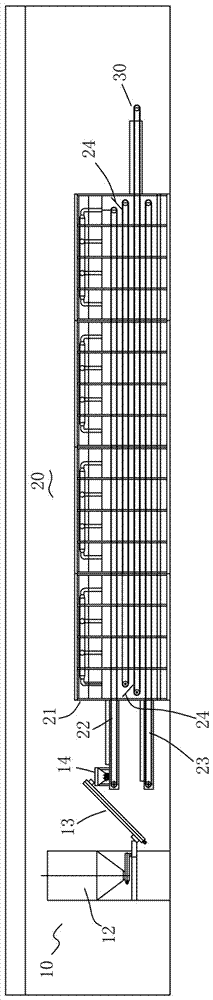

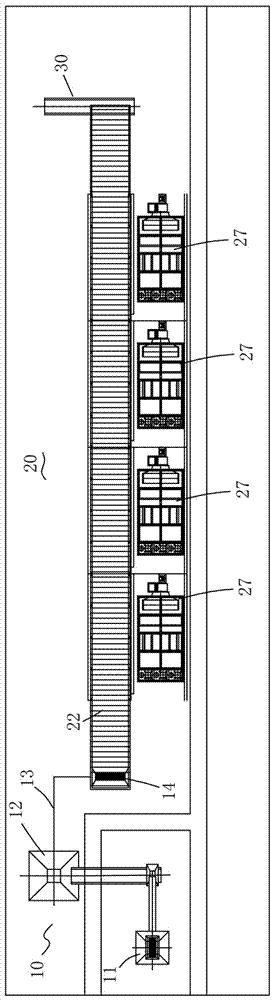

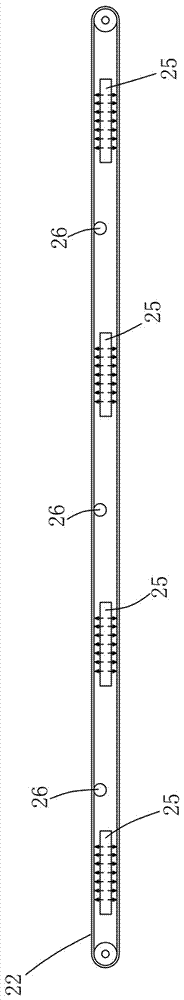

[0031] refer to figure 1 , 2 , 3, and 4 are schematic diagrams of a preferred embodiment of the present invention. The present invention relates to a dehumidification and drying system for rapidly sterilizing sludge with electromagnetic energy. The system has a feeding part 10, a drying line 20 and a discharging part 30 , the feeding part 10 is connected to the feeding end of the drying line 20 , and the discharging part 30 is connected to the discharging end of the drying line 20 . In this embodiment, the feeding part 10 has a crushing conveyor unit 11 with a feed hopper, and a storage bin 12 with a feeding screw; the crushing conveyor unit 11 receives wet sludge in plates, and obtains sludge of a suitable size after crushing. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com