Double-end hybrid excitation stator-partition-type flux switching motor

A magnetic flux switching motor and mixed excitation technology, applied in the direction of motor, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problems of reducing air gap magnetic density and power density, unable to guarantee the range of magnetic field adjustment, and weakening the magnetic field , achieve high torque density and power density, improve space utilization, and reduce copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

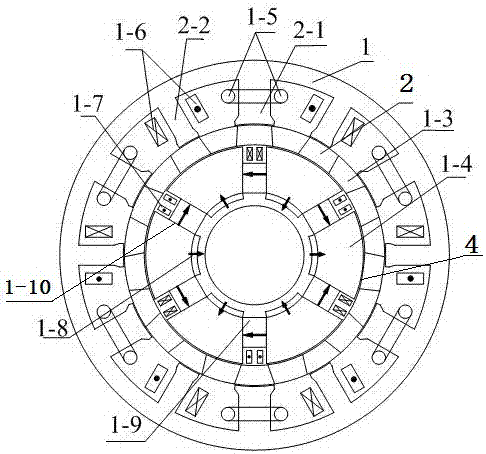

[0023] Such as figure 1 As shown, the present invention includes an outer stator 1, an intermediate rotor 2 and an inner stator 4, the outer stator 1 is coaxially sleeved outside the intermediate rotor 2, the intermediate rotor 2 is coaxially sleeved outside the inner stator 4, the outer stator 1, the inner stator 4 and Radial air gaps are left between the intermediate rotors 2, so the present invention has two layers of radial air gaps. The radial air gaps between the intermediate rotor 2 and the inner stator 4 and the outer stator 1 on the inner and outer sides are equal, and the air gap ranges from 0.4 to 0.6 mm.

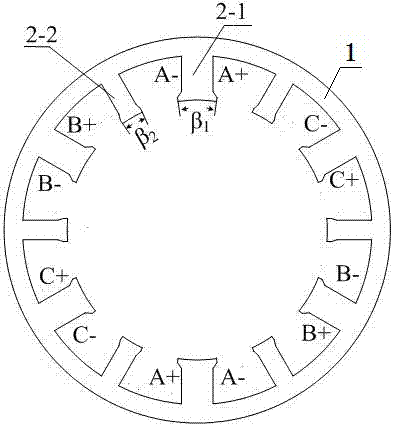

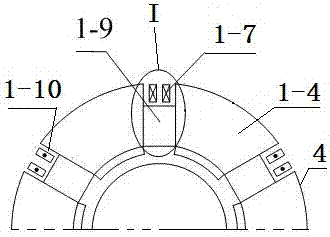

[0024] recombine figure 2 , the outer stator 1 is composed of armature teeth 2-1, excitation teeth 2-2, armature windings 1-5 and outer DC excitation windings 1-6, and the inner surface of the stator yoke of the outer stator 1 is uniformly arranged with armatures along the circumferential direction The tooth 2-1 and the field tooth 2-2, the armature tooth 2-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com