Dismantling device of power battery

A power battery and equipment technology, applied in the field of power battery dismantling equipment, can solve the problems of non-continuous production process, contact with battery waste liquid, low efficiency, etc., and achieve reasonable structural design, improve work efficiency and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

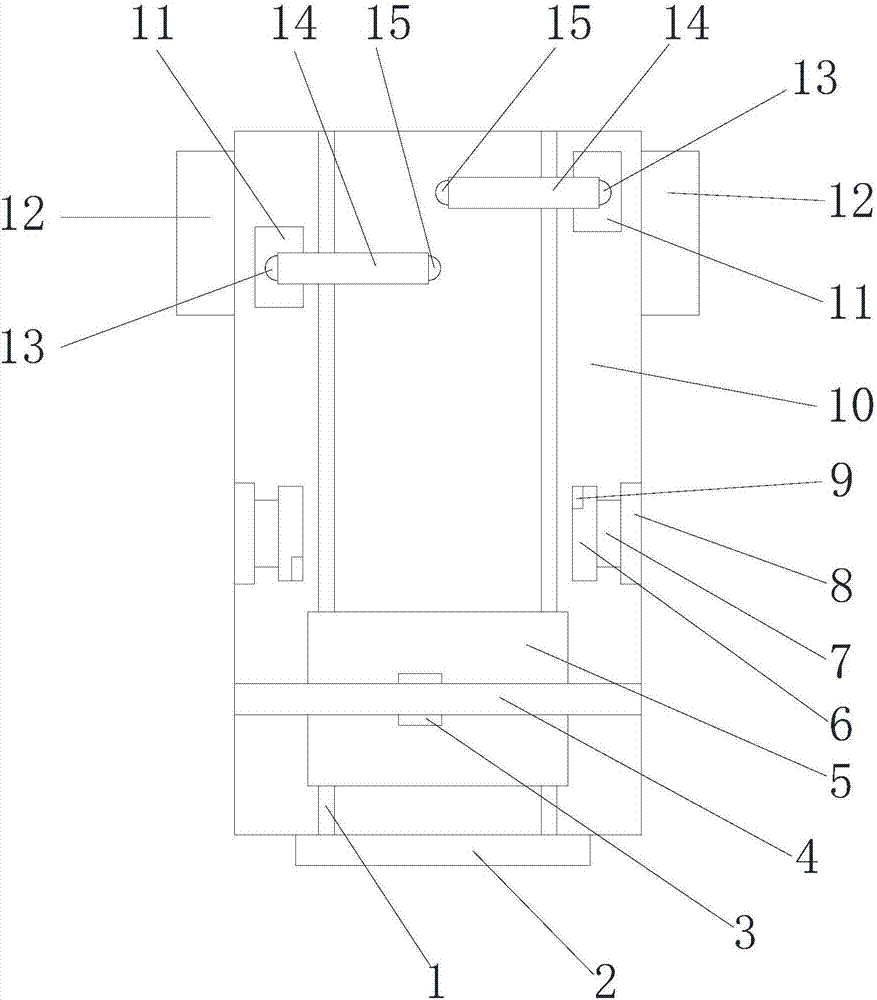

[0016] Such as figure 1 As shown, a dismantling equipment for a power battery includes a feeding seat 2 and a frame corresponding to the feeding seat. mobile cutting mechanism. A shell collection mechanism and a core body collection mechanism are provided on the side of the frame away from the material loading seat. The frame is provided with a controller, and the controller is connected with the conveying mechanism, the moving cutting mechanism, the casing collecting mechanism and the core body collecting mechanism.

[0017] The transmission mechanism includes a pair of rails 1 arranged on the frame, on which a conveyor belt is arranged, and the conveyor belt is connected to a motor arranged in the frame. The motor is connected to the controller.

[0018] The moving cutting mechanism includes a moving plate 5 installed on a rail, a cutting frame 4 mounted on the moving plate 5, and a cutting tool 3 mounted on the cutting frame. Clamping motors 8 are respectively arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com