Well cementation cement sheath integrity analysis and forecast method and device

A technology of cementing cement and prediction method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as seal failure and actual working conditions at the bottom of the well that cannot be truly reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

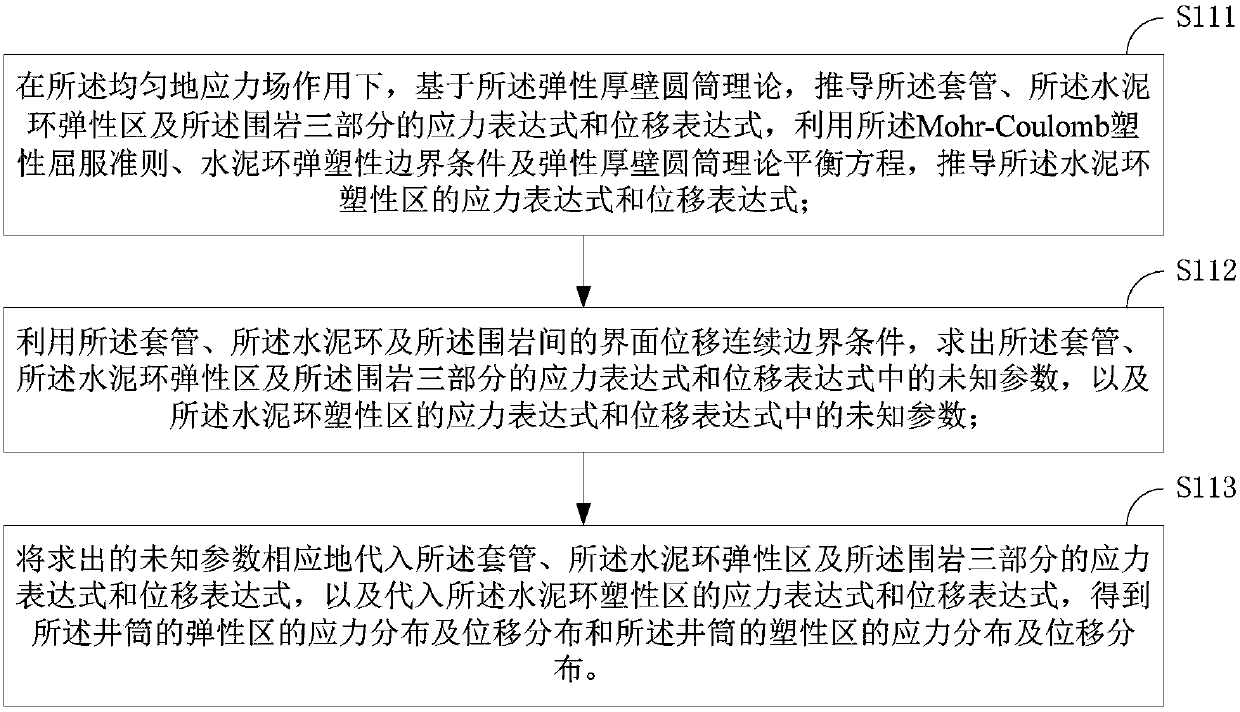

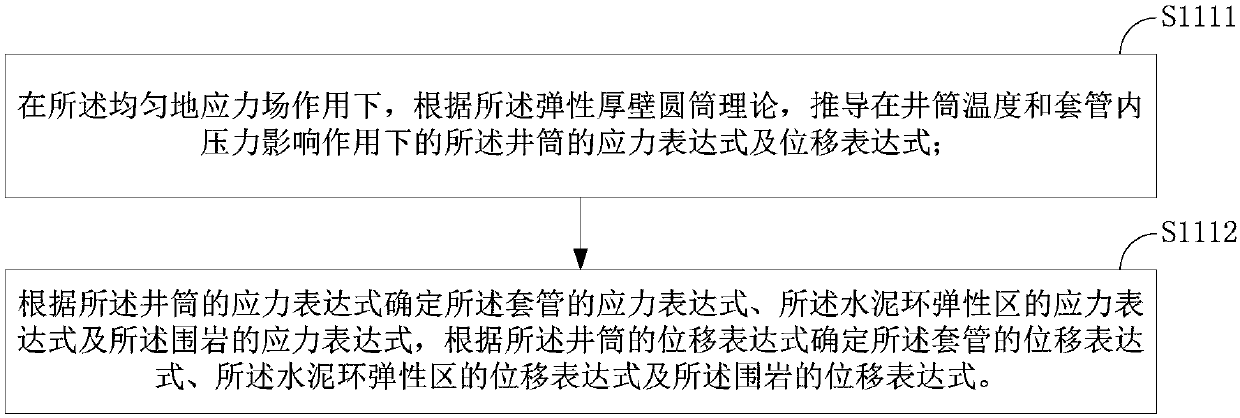

Method used

Image

Examples

Embodiment 1

[0372] Embodiment 1: A cementing-interface bonding strength testing device, including the cementing main body, the upper clamping part and the lower clamping part described in the cementing-interface bonding strength maintenance device;

[0373] The cementing-interface bonding strength maintenance device includes at least one cementing body, and the cementing body includes:

[0374]The curing cylinder is formed by clamping a plurality of cylinder blocks along the axial direction of the curing cylinder, and has an upper end opening and a lower end opening;

[0375] The lower sealing body supports and seals the lower opening;

[0376] The upper sealing device includes an upper sealing body and a force transmission screw, the force transmission screw is vertically connected to the lower surface of the upper sealing body, the upper sealing body fixes and seals the upper opening, and the force transmission screw extends into the inner cavity of the curing cylinder;

[0377] Where...

Embodiment 2

[0380] Embodiment 2: In the cementing-interface bonding strength testing device as described in Embodiment 1, two adjacent cylinder blocks are clamped together through their stepped side ends.

Embodiment 3

[0381] Embodiment 3: The cementing-interface bonding strength testing device as described in Embodiment 1, the curing cylinder is in the shape of a cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com