A kind of underground gas sampling device and method of coal mine

A gas sampling and coal mine technology, applied in the direction of sampling devices, etc., can solve the problems of cumbersome procedures, large carrying volume, and reduced accuracy, so as to ensure the safety of personnel, facilitate the operation of the method, and improve enthusiasm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

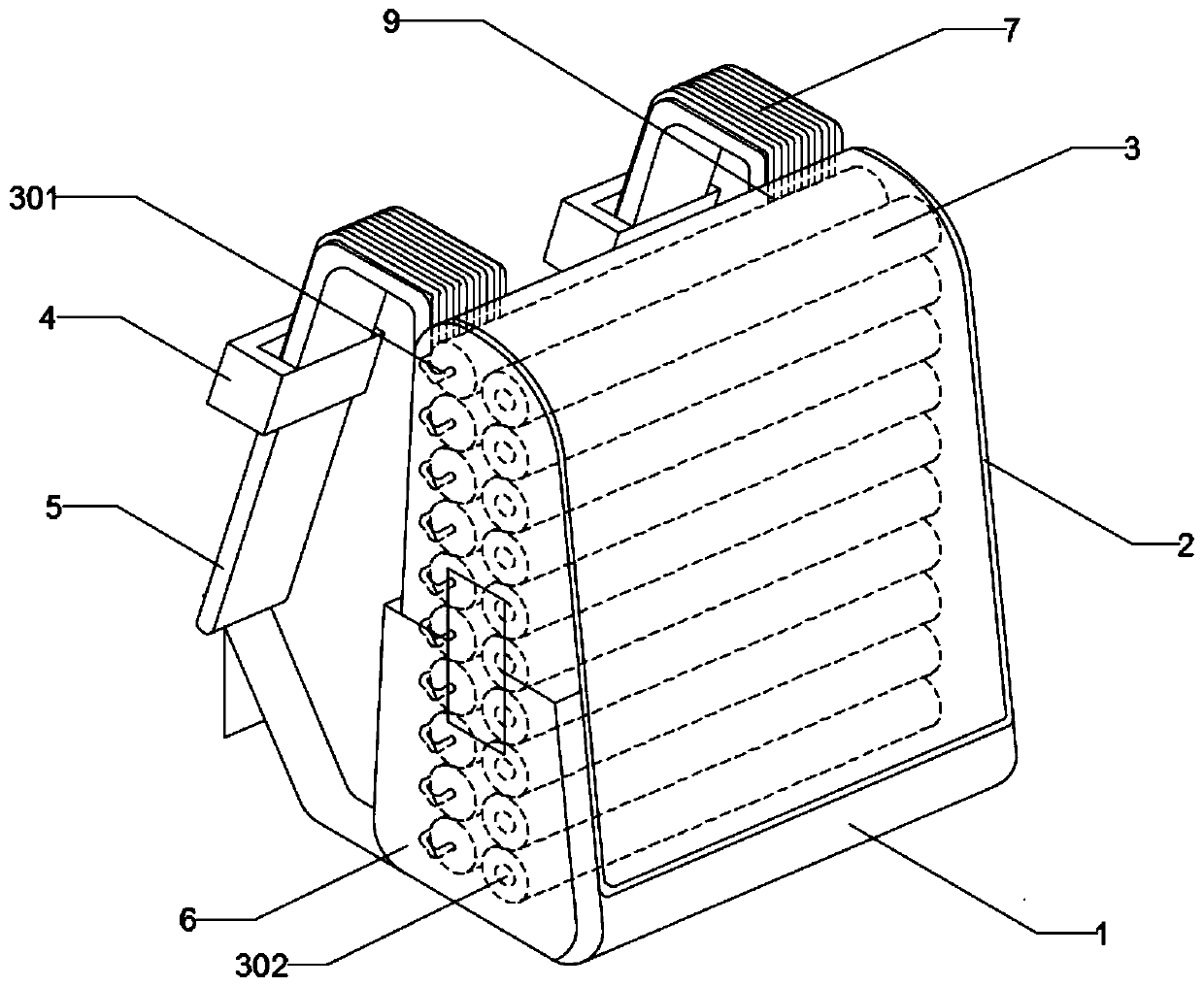

[0054] Such as Figure 1-5As shown, a coal mine underground gas sampling device includes an enclosure 1, a gas storage tank 3, a rubber tube 7, a nozzle switch 4 and a portable air pump, and the portable air pump is an intrinsically safe air pump for mine use, wherein:

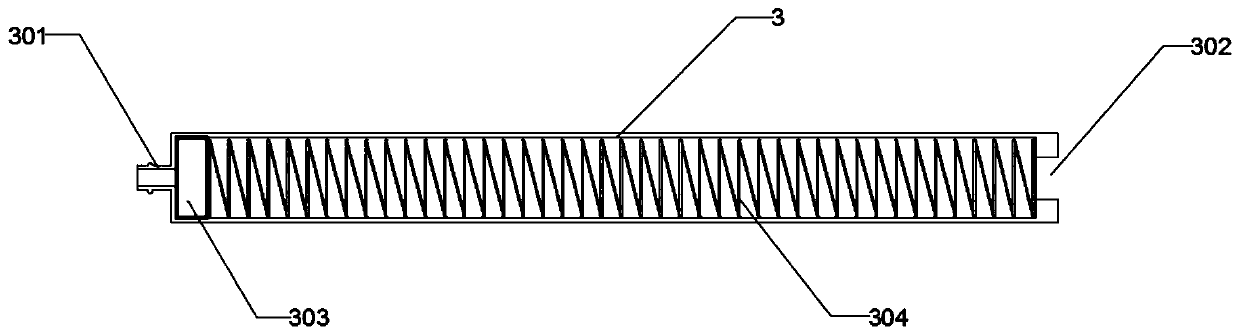

[0055] The number of the gas storage tanks 3 is determined according to the number of gases to be sampled. In this embodiment, 20 gas storage tanks are arranged and placed side by side in the package body 1. One end of the gas storage tanks 3 is provided with a gas storage tank air inlet 301 , the other end is provided with gas storage tank exhaust opening 302; described gas storage tank air inlet 301 place is provided with gas piston 303, and described gas storage tank 3 is provided with return spring 304, and described gas piston 303 and return spring 304 is connected;

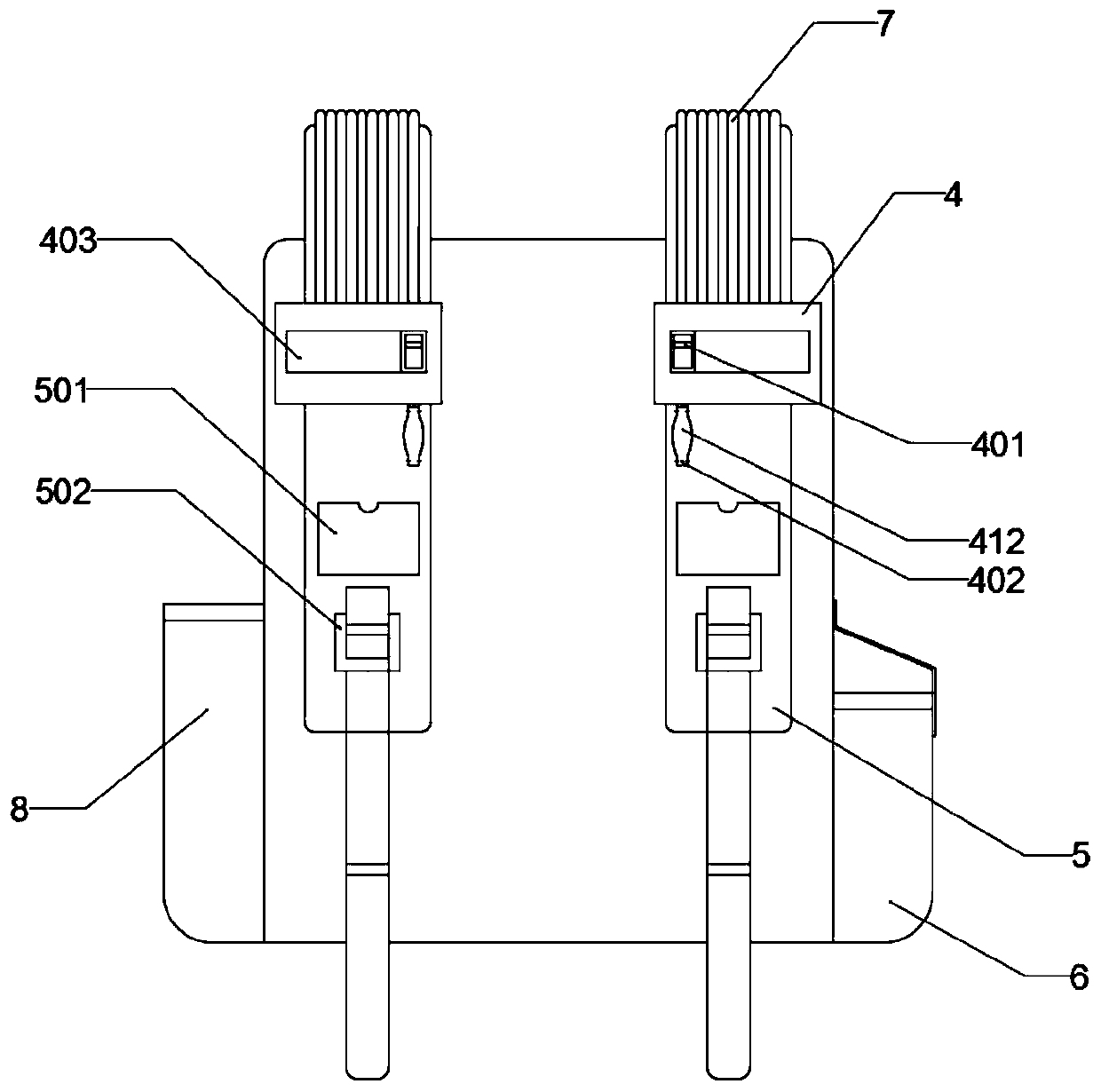

[0056] The nozzle switch 4 includes a connecting pipe 413, a switch 401, a switch chute 403, a track 408, a rubber air bag 412 and 20 rubb...

Embodiment 2

[0075] A kind of coal mine gas sampling device in this embodiment is the same as Embodiment 1, the difference is that in this embodiment, there are 10 gas storage cylinders, and 10 rubber tubes, and 10 rubber tube inlets and outlet openings are also respectively set; The continuous collection of gas samples is used to observe the change of gas sample composition over time; in this example, the release of tracer gas at the upper corner requires continuous collection of the lower corner of the goaf for a period of time. According to the capacity of the portable air pump flow rate and the gas storage cylinder, the collection start and end time of each gas sample are determined, and the method for gas sampling using the coal mine underground gas sampling device specifically includes the following steps:

[0076] (1) Insert the air inlet of the portable air pump into the lower corner of the wind barrier, connect the air outlet of the portable air pump to the air inlet of the rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com