A kind of preparation method of carbon nanotube-magnesium aluminate composite material and prepared material

A carbon nanotube and composite material technology, which is applied in the field of preparation methods and prepared materials, can solve the problem of low electrical conductivity and the like, and achieves the effects of simple preparation process, increased Seebeck coefficient, and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the carbon nanotube-magnesium aluminate composite material of the embodiment of the present invention, the method comprises the following steps:

[0029] 1) Mix seaweed-like magnesium aluminate powder and carbon nanotubes, add them to the solvent, disperse them ultrasonically for 10-60 minutes, and stir them ultrasonically for 10-60 minutes to obtain a solution, heat the solution to 50-100°C, and evaporate the solvent to obtain a powder body, grinding the powder for 10 to 60 minutes;

[0030] 2) performing spark plasma sintering on the ground powder in step 1) to obtain the carbon nanotube-magnesium aluminate composite material;

[0031] Wherein, the spark plasma sintering includes: the heating rate is 10-100°C / min, the green body sintering pressure is 20-80MPa, the holding temperature is 1100-1300°C, and the holding time is 5-20min;

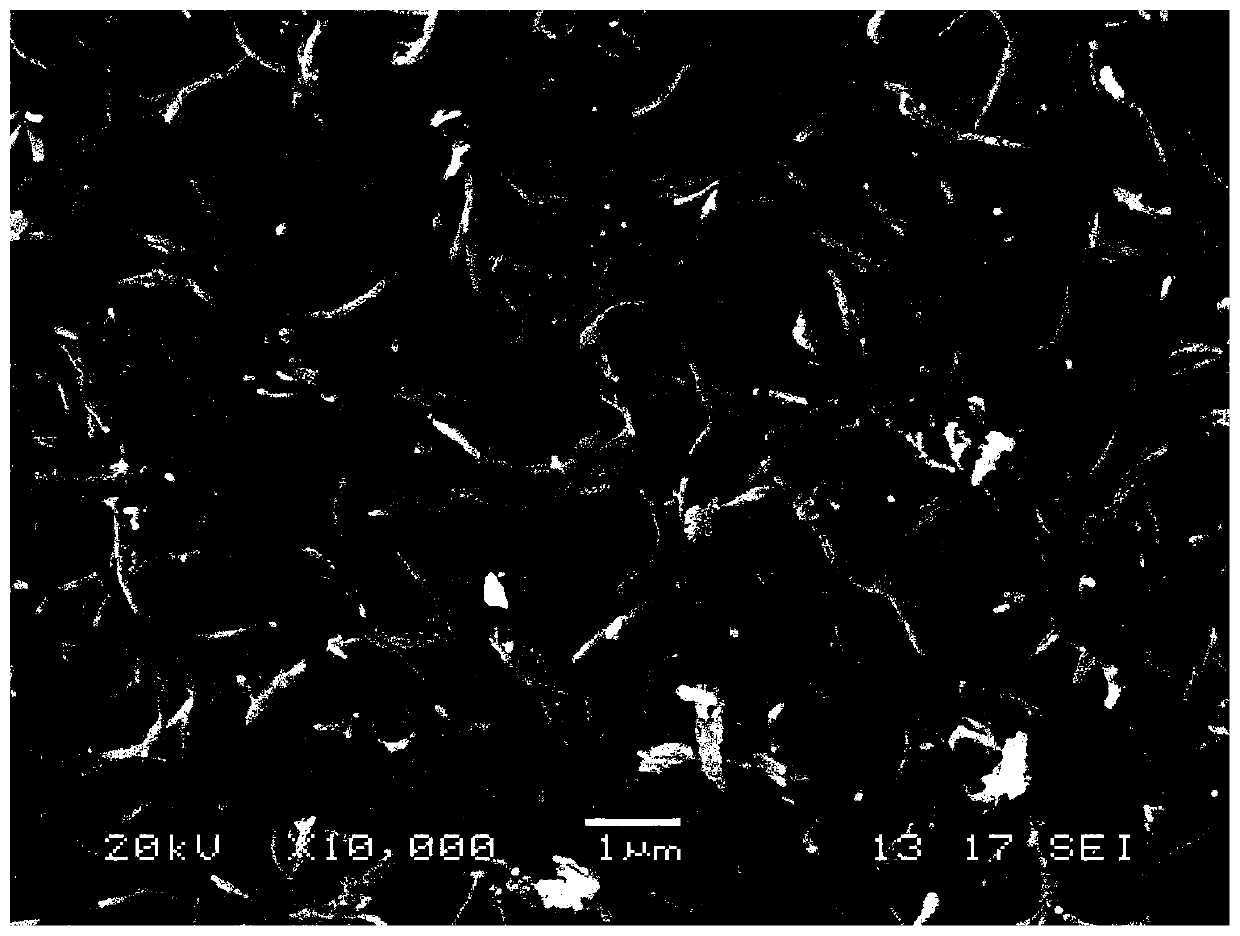

[0032] The seaweed-like magnesium aluminate powder includes flake-like magnesium aluminate nanocrystals bridg...

Embodiment 1

[0045] Embodiment 1 of the present invention The preparation method of carbon nanotube-magnesium aluminate composite material comprises the following steps:

[0046] 1) Mix seaweed-like magnesium aluminate powder and carbon nanotubes (the mass fraction of carbon nanotubes after mixing is 0.1wt%), add to 100mL isopropanol solvent, ultrasonically disperse for 10min, and then ultrasonically stir for 10min To obtain a solution, the solution was heated to 50° C., the solvent evaporated slowly, and the obtained powder was ball-milled for 10 min.

[0047] 2) The powder prepared in step 1) was subjected to spark plasma sintering, the heating rate of spark plasma sintering was 10°C / min, the sintering pressure of the ceramic green body was 20MPa, the holding temperature was 1100°C, and the holding time was 5min to obtain carbon nanotube-magnesium aluminate ceramic composites.

[0048] The preparation method of the seaweed-like magnesium aluminate powder comprises:

[0049] Dissolve 10...

Embodiment 2

[0053] The preparation method of embodiment 2 of the present invention carbon nanotube-magnesium aluminate composite material comprises the following steps:

[0054] 1) Mix seaweed-like magnesium aluminate powder and carbon nanotubes (the mass fraction of carbon nanotubes after mixing is 50wt%), add to 500mL isopropanol solvent, ultrasonically disperse for 60min, and then ultrasonically stir for 60min to obtain solution, the solution was heated to 100° C., the solvent evaporated slowly, and the obtained powder was ball-milled for 60 minutes.

[0055] 2) The powder prepared in step 1) was subjected to spark plasma sintering, the spark plasma sintering heating rate was 100°C / min, the sintering pressure of the ceramic green body was 80MPa, the holding temperature was 1300°C, and the holding time was 20min to obtain carbon nanotube-magnesium aluminate ceramic composites.

[0056] The preparation method of the seaweed-like magnesium aluminate powder comprises:

[0057] Dissolve 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com