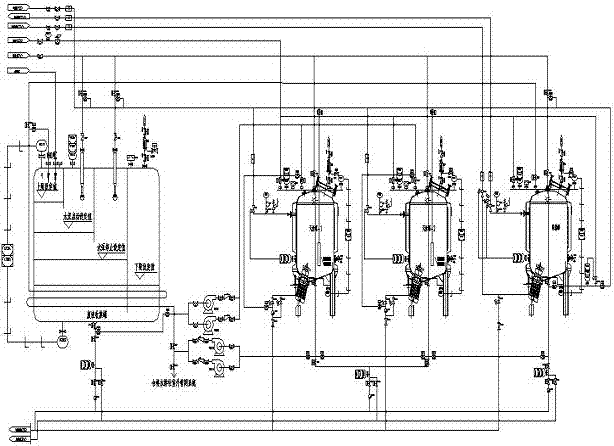

GMP workshop virus-containing waste liquid steam inactivation system energy-saving process design

A technology of process design and virus, applied in the field of energy-saving process design of the steam inactivation system of virus-containing waste liquid in GMP workshop, can solve the problems of low comprehensive utilization rate of energy consumption, low use flexibility rate, high operating cost, etc., and improve the collection and buffer capacity , avoid cross risk, reduce the effect of leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

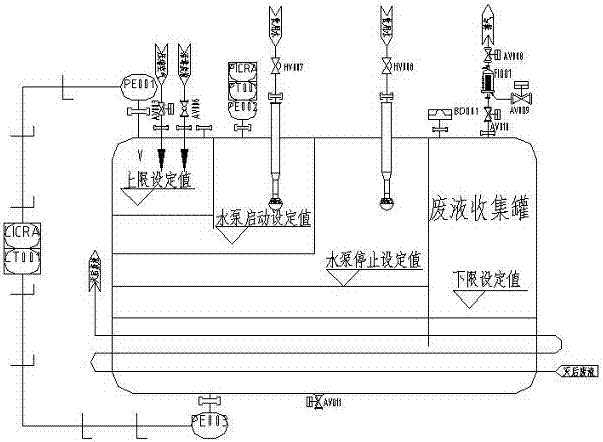

[0047] Valve initial state: HV001, HV002, HV003, HV004, HV005, HV006, HV007, HV008, HV009, HV011, HV012, HV015, HV017, HV019, HV021, HV022, HV023, HV024, HV025, HV026 closed, other valves open,

[0048] Waste liquid collection tank liquid inlet operation mode

[0049] 1. AV010 and AV008 are turned on, and the waste liquid collection tank is under normal pressure;

[0050] 2. Virus-containing waste liquid flows into the waste liquid collection tank through the liquid inlet pipe;

[0051] 3. Liquid level monitoring is realized through LT001;

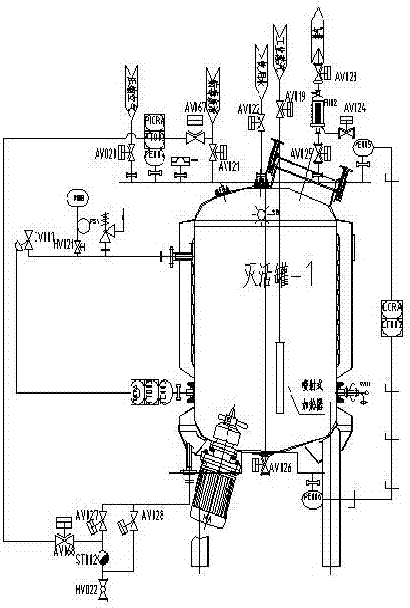

[0052] Inactivation tank-1 full liquid inactivation operation mode

[0053] 1. Liquid intake: When the virus-containing waste liquid reaches the upper-line setting value of the liquid level of the waste liquid collection tank, AV011, AV012, AV016, and AV021 are turned on, and PU001 (or PU002, two pumps are used alternately intermittently, one for backup and one for use) starts , pump the virus-containing waste liquid into the inactivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com