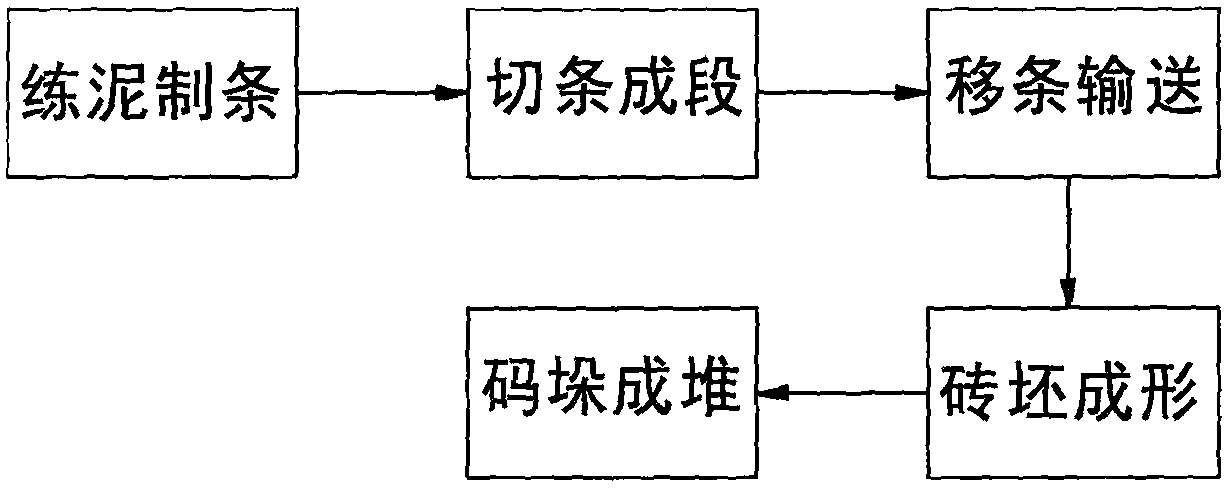

Brick Cutting Technology of Circular Rotary Tunnel Kiln

A rotary, tunnel kiln technology, used in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve problems such as affecting the production efficiency of brick kilns and falling bricks, so as to reduce the number of grabs, reduce investment, and avoid falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

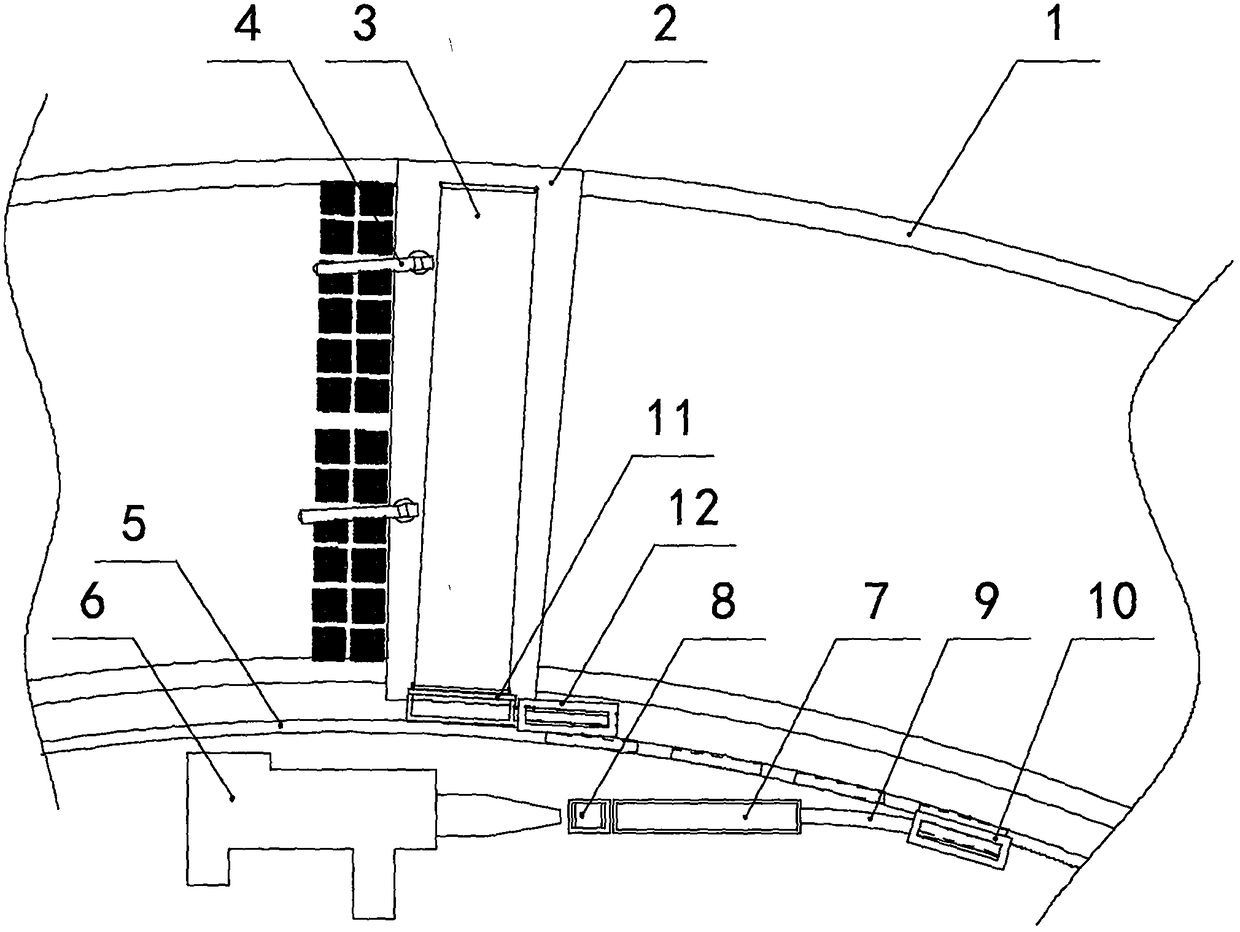

[0015] The brick cutting and coding process of the annular rotary tunnel kiln of the present invention mainly relates to the brick forming and stacking process in the production process of sintered bricks, and the production equipment involved is such as figure 2 As shown, it includes an annular track 1 that forms a concentric circle structure and a stacking platform 2 that moves along the annular track 1. On the stacking platform 2, two stacking robots 4 are installed at intervals along the tangential direction of the annular track 1 and are equipped with a layout. The blank conveyor 3 is connected with a blank cutter 11 at the inner end of the blank conveyor 3 and is equipped with a secondary strip moving machine 12 . Concentrically installed with ring conveyor 5 in the inner side of ring track 1, strip making equipment 6, strip cutting machine 7 are installed at the inboard of ring conveyor 5, mud bar transition frame 8 is installed at the entrance of strip cutting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com