Microcapsule with porous double-layer capsule wall and preparation method of microcapsule

A technology of microcapsules and capsule walls, which is applied in the field of porous double-layer capsule wall microcapsules and its preparation, which can solve the problems of poor controlled release of epoxy resin capsule wall materials, unstable performance of microcapsules, and difficult industrial production of pore-forming methods and other issues to achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 10% Beta-cyhalothrin microcapsule suspension

[0050] Take by weighing 10.29g 97.2% lambda-cyhalothrin former medicine, 15g biodiesel, 5g novolac epoxy resin, 0.3g polyisocyanate, 0.5g 2,6-bis[(dimethylamino)methyl]phenol and stir to obtain Oil phase; dissolve 0.1g polyvinyl alcohol, 3.0g sodium lignosulfonate, and 1.55g castor oil polyoxyethylene ether in 50g water, and stir evenly to obtain the water phase; at 30°C, mix the oil phase and the water phase, Homogeneous emulsification to obtain a stable O / W emulsion; then transfer the emulsion to a three-necked flask, stir at 300 rpm; slowly add 10% diamine aqueous solution dropwise, adjust the pH=7.5-8.0, and use organic Adjust the pH to 6.5-7.0 with acid; raise the temperature to 50°C, slowly add 1g of 10% 2,6-bis[(dimethylamino)methyl]phenol aqueous solution dropwise, and react for 0.5 hours; continue to raise the temperature to 60°C, and react for 3 hours; Lower the temperature of the solution to 30°C, add 4g of ethy...

Embodiment 2

[0054] 10% Beta-cyhalothrin microcapsule suspension

[0055] The preparation method is the same as in Example 1, except that the amount of "10% 2,6-bis[(dimethylamino)methyl]phenol aqueous solution" is increased to 4g.

[0056] The encapsulation rate of this sample is 94.2%; the suspension rate is 92%; the dumping residue is less than 0.5%; the 75 μm wet sieve residue is less than 0.5%; the persistent foaming property is less than 20 mL; the freeze-thaw stability is qualified; the thermal storage stability is qualified .

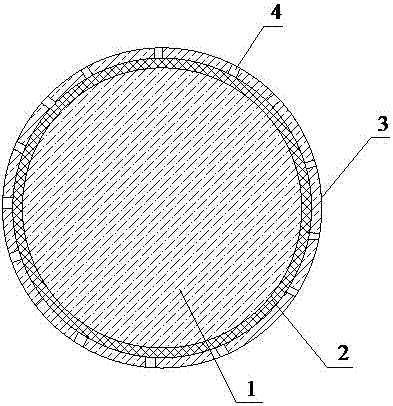

[0057] Scanning electron microscope picture as Figure 4 As shown, the diameter of the circular hole 4 on the capsule wall is 500-1000 nm, and the number of holes increases.

[0058] Compared image 3 and Figure 4 It can be seen that increasing the amount of 2,6-bis[(dimethylamino)methyl]phenol can increase the number and size of pores on the capsule wall.

Embodiment 3

[0060] 20% pendimethalin microcapsule suspension

[0061] Take by weighing 20.62g 97% pendimethalin former medicine, 10g150# solvent naphtha, 5.5g novolac epoxy resin, 0.35g polyisocyanate, 0.5g 2,6-bis[(dimethylamino)methyl]phenol and stir to obtain Oil phase; dissolve 0.1g polyvinyl alcohol, 5.4g calcium lignosulfonate, and 2.2g castor oil polyoxyethylene ether in 50g water, and stir evenly to obtain the water phase; at 30°C, mix the oil phase and the water phase, Homogeneous emulsification to obtain a stable O / W emulsion; then transfer the emulsion to a three-necked flask, stir at 300 rpm; slowly add 10% diamine aqueous solution dropwise, adjust the pH=7.5-8.0, and use organic Adjust the pH to 6.5-7.0 with acid; raise the temperature to 50°C, slowly add 1.5g of 10% 2,6-bis[(dimethylamino)methyl]phenol aqueous solution dropwise, and react for 0.5 hours; continue to raise the temperature to 60°C, and react for 3 hours ; Lower the temperature of the solution to 30°C, add 4g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com