Continuous countercurrent extraction process and device for1,5-pentamethylene diamine

A pentamethylene diamine and extraction technology, applied in countercurrent extraction, solvent extraction, liquid solution solvent extraction and other directions, can solve the problems of salt crystal blocking the pipeline, affecting the extraction effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

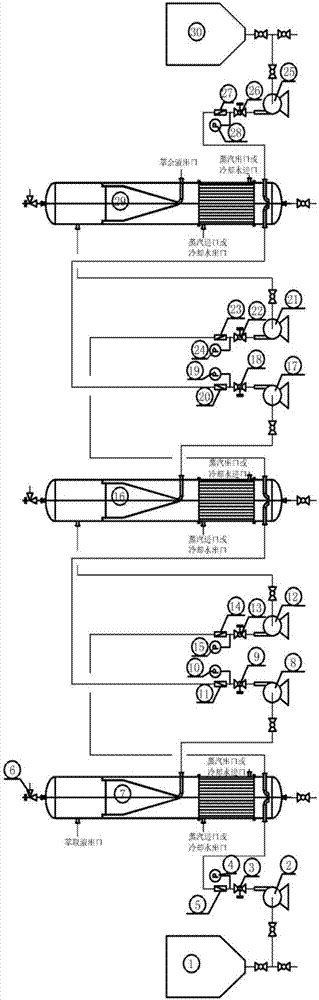

[0039] Example 1: This example illustrates the composition and connections of a complete set of equipment for extracting and obtaining 1,5-pentanediamine from an enzyme conversion liquid system

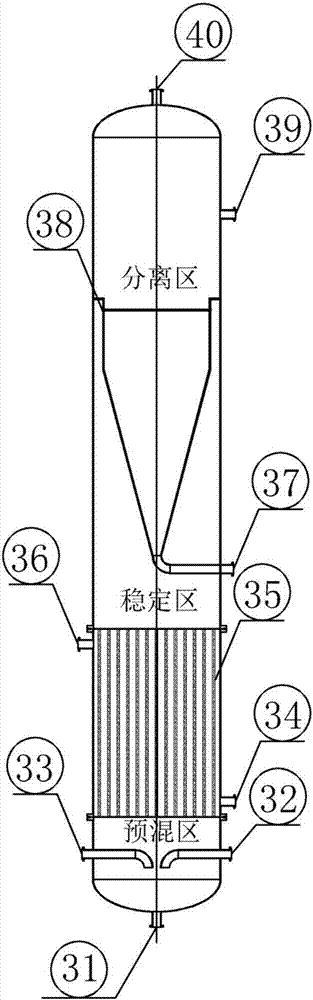

[0040] A schematic diagram of the complete set of equipment is attached figure 1 shown. Specifically, the equipment contains modular 1,5-pentamethylenediamine enzyme conversion liquid tank (1), pump (2), numerical control valve (3), pressure gauge (4), flow meter (5), extraction tower ( 7), pump (8), numerical control valve (9), pressure gauge (10), flow meter (11), extraction tower (16), pump (17), numerical control valve (18), pressure gauge (19), flow rate Meter (20), extraction tower (29); n-butanol barrel (30), pump (25), numerical control valve (26), pressure gauge (28), flow meter (27), extraction tower (29), pump (21), numerical control valve (22), pressure gauge (24), flow meter (23), extraction tower (16), pump (12), numerical control valve (13), pressure gauge (15), flow ...

Embodiment 2

[0044] Embodiment 2: This embodiment illustrates the process of extracting 1,5-pentanediamine from the enzyme conversion liquid system

[0045] After the solid-liquid separation of the enzyme conversion liquid, adjust the pH value to 13 with sodium hydroxide aqueous solution in a stainless steel reaction tank, and react at a temperature of 80 ° C for 5 hours. During the reaction, the pH value is continuously adjusted to 13. After the reaction is completed, cool to 40 ℃ for extraction, the solution temperature was kept at 40 ℃ during the extraction, the volume ratio of enzyme conversion liquid and n-butanol was 6:5, and the extraction rate was 97.5%. As shown in Table 1, it shows that the volume ratio of enzyme conversion solution and n-butanol is 5:4, and the ratio of the flow rate of extractant n-butanol to the solution flow rate is 43:50.

[0046] Table 1 Effect of flow and volume ratio of extractant to solution on extraction rate

[0047] Flow (l / min) Content o...

Embodiment 3

[0048] Embodiment 3: this embodiment illustrates the situation of implementing the process of the present invention in the equipment of embodiment 1

[0049] Take 500L of 1,5-pentanediamine enzyme conversion solution, the concentration of 1,5-pentanediamine is 141.18g / L, first adjust the pH value to 13 with aqueous sodium hydroxide solution in a stainless steel reaction tank, and react at a temperature of 80°C for 5 hour, constantly adjust the pH value in the reaction process to be 13, the reaction is finished, cooled to 40 ℃, then poured into the barrel (1), and poured n-butanol into the barrel (30), according to the enzymatic conversion liquid feed tank ( 1) Through pumps (2), (8), (25), numerical control valves (3), (13), (22), flow meters (5), (11), (20), pressure gauges (4), (10), (19) are successively extracted step by step, the extractant n-butanol tank (30) passes through pumps (25), (21), (12), numerically controlled valves (26), (22), (13), Flow meters (27), (23), (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com