Biodegradable stress-free isolated digestive tract capsulated anastomat and preparation method thereof

A tension-free, digestive tract technology, applied in drug delivery, pharmaceutical formulations, coatings, etc., can solve the problems of non-degradable staplers and life-threatening patients, shorten the overall treatment cycle, reduce medical expenses, and avoid secondary pain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

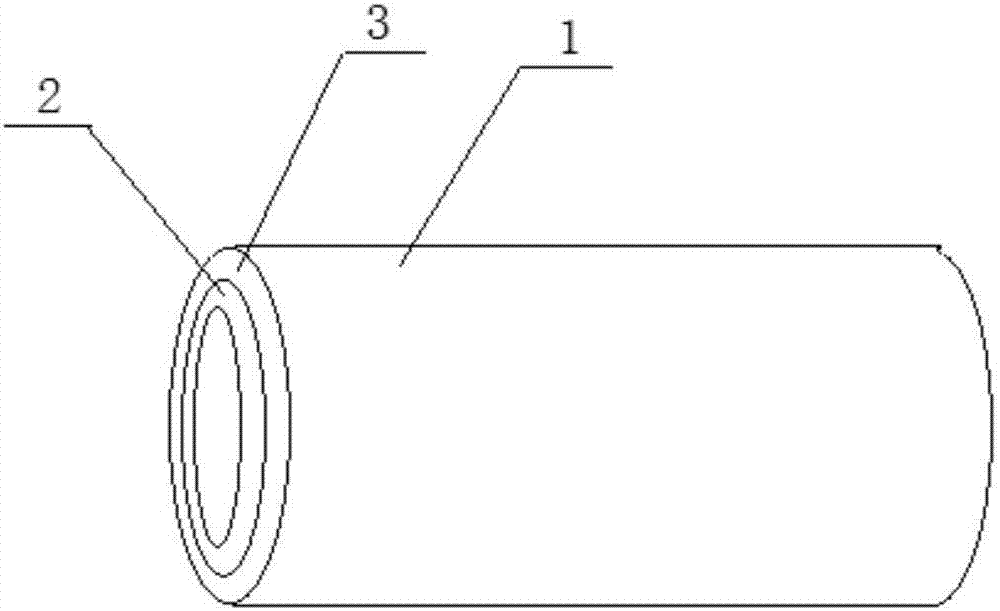

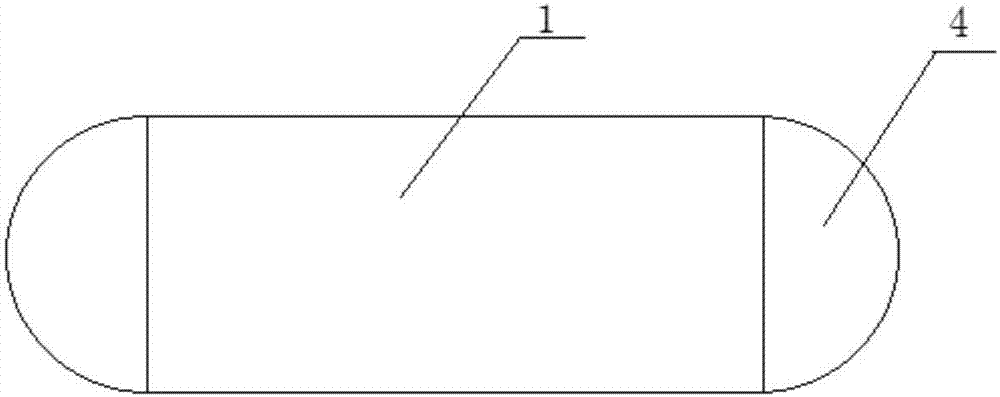

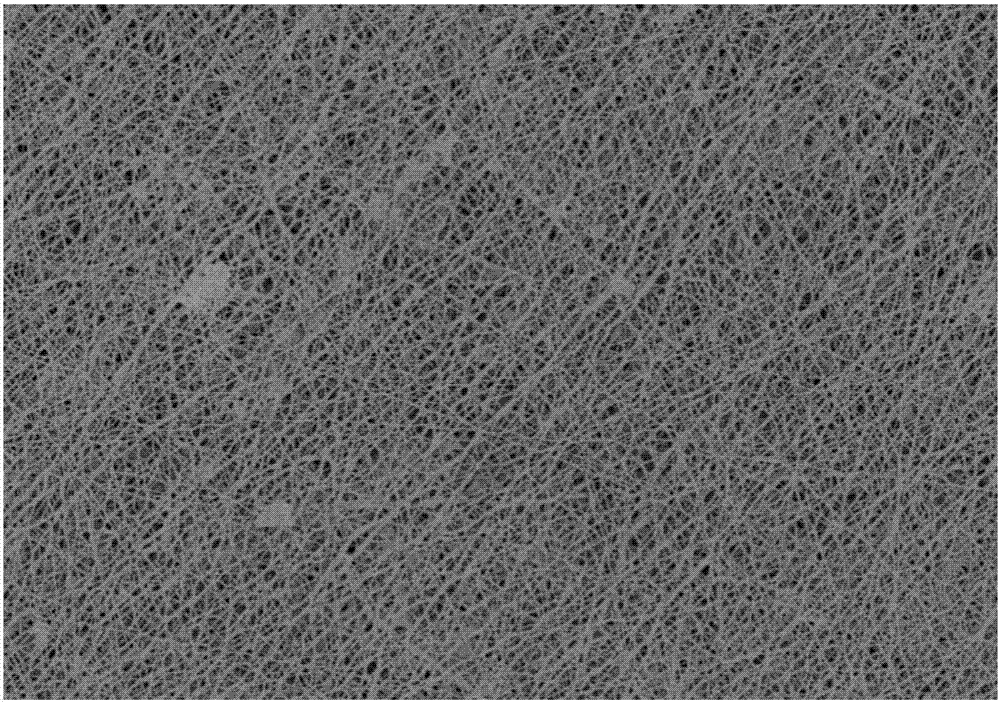

[0029] Biodegradable Tension-Free Isolation Gastrointestinal Capsule Stapler, see figure 2 , including body tube 1, see figure 1 , the main tube is composed of a network skeleton structure layer 2 and a hydrophobic nanofiber membrane layer 3 coated on the outer surface of the network skeleton structure layer 2, and a hemispherical hydrophilic nanofiber membrane is respectively connected to both ends of the main tube Capping 4.

[0030] The material of the network skeleton structure is poly-L-lactide with a weight average molecular weight of 1 million.

[0031] The material of the hydrophobic nanofiber membrane is poly(L-lactide-copoly-glycolide) with a weight average molecular weight of 200,000;

[0032] The hydrophilic nanofiber membrane material is a mixture of polyvinyl alcohol with a weight-average molecular weight of 5,000 and an alcoholysis degree of 88% and gelatin with a glue strength of 100g Bloom in a mass ratio of 1:1;

[0033] A preparation method of a biodegra...

Embodiment 2

[0039] The biodegradable tension-free capsule-type stapler for isolating the digestive tract includes a main body tube 1, the main tube is composed of a network skeleton structure layer 2 and a hydrophobic nanofiber membrane layer 3 coated on the outer surface of the network skeleton structure layer 2, Both ends of the main tube are respectively connected with semi-capsule-shaped hydrophilic nanofiber membrane capping ends 4 .

[0040]The material of the network skeleton structure is a mixture of poly-L-lactide with a weight average molecular weight of 200,000 and poly-D-lactide with a weight average molecular weight of 200,000 in a mass ratio of 1:1.

[0041] The material of the hydrophobic nanofiber membrane is: poly-ε-caprolactone with a weight average molecular weight of 200,000 and polydioxanone with a weight average molecular weight of 200,000 are mixed in a mass ratio of 1:1.

[0042] Preferred hydrophilic nanofiber membrane material: mix polyvinylpyrrolidone with a wei...

Embodiment 3

[0049] The biodegradable tension-free capsule-type stapler for isolating the digestive tract includes a main body tube 1, the main tube is composed of a network skeleton structure layer 2 and a hydrophobic nanofiber membrane layer 3 coated on the outer surface of the network skeleton structure layer 2, Both ends of the main tube are respectively connected with hemispherical hydrophilic nanofiber membrane capping ends 4 .

[0050] The material of the network skeleton structure: a mixture of polyglycolide with a weight-average molecular weight of 400,000 and poly(L-lactide-co-glycolide) with a weight-average molecular weight of 400,000 in a mass ratio of 1:1 .

[0051] The material of the hydrophobic nanofibrous membrane: poly(L-lactide-copoly-glycolide) with a weight-average molecular weight of 100,000 and polydioxanone with a weight-average molecular weight of 100,000 are 1 in mass ratio: Mix at a ratio of 1.

[0052] Hydrophilic nanofiber membrane material: polyacrylic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com