Production method of composite lithium ribbon

A production method and technology of composite lithium, applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve problems such as limited development space for specific capacity, and achieve the effect of improving production efficiency and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

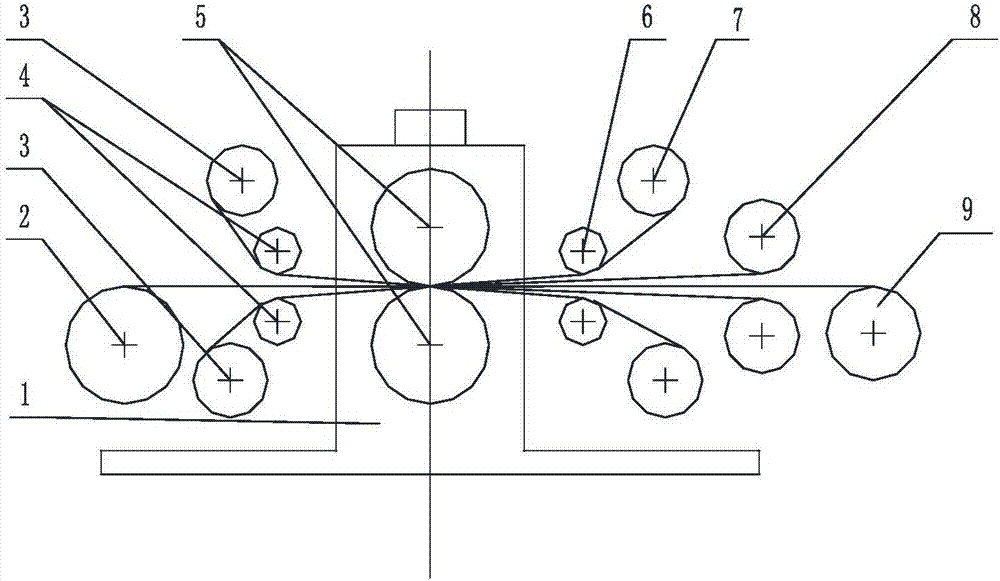

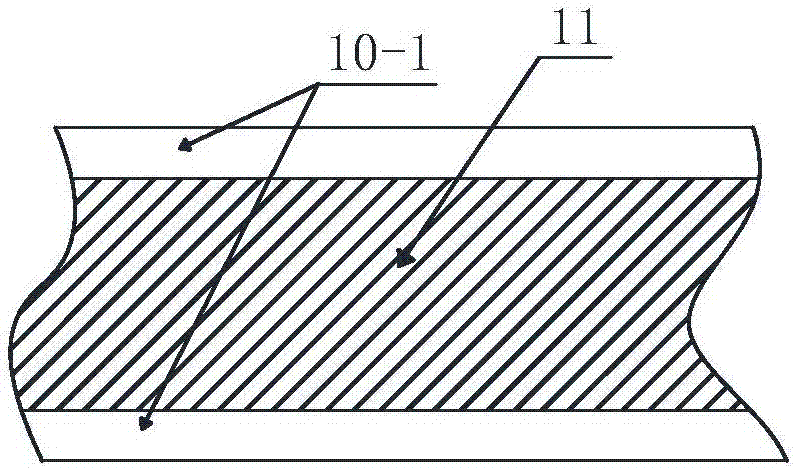

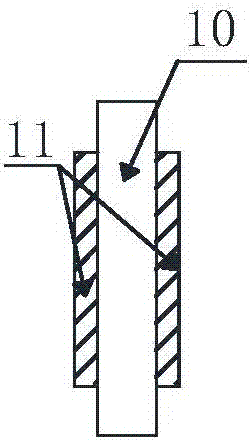

[0021] See figure 1 , A method for producing a composite lithium belt, which adopts roll forming. During the roll pressing, a protective film is used to cover the lithium belt or lithium alloy belt. The protective film and the lithium belt or lithium alloy belt and the current collector are on the roll. Synchronous operation during press production, that is, synchronously enters between the rolls and synchronously leaves between the rolls.

[0022] In this embodiment, the relative humidity of the production environment of the composite lithium belt is relatively strict, and 1% or less is appropriate. The protective film can be any one of polyethylene film, polypropylene film, nylon film, polyurethane film, polyvinyl chloride film, polyterephthalate film and polyimide film, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com