Thick layer glutenite horizontal well three-dimensional seam net fracturing optimization method

An optimization method and technology for horizontal wells, which are applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., which can solve the problems of inconsistent fracture network, high land acquisition cost, and small swept range, so as to facilitate centralized drilling and reduce land acquisition. cost, avoid the effect of mutual channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings.

[0019] The invention has been developed and verified in a thick glutenite block:

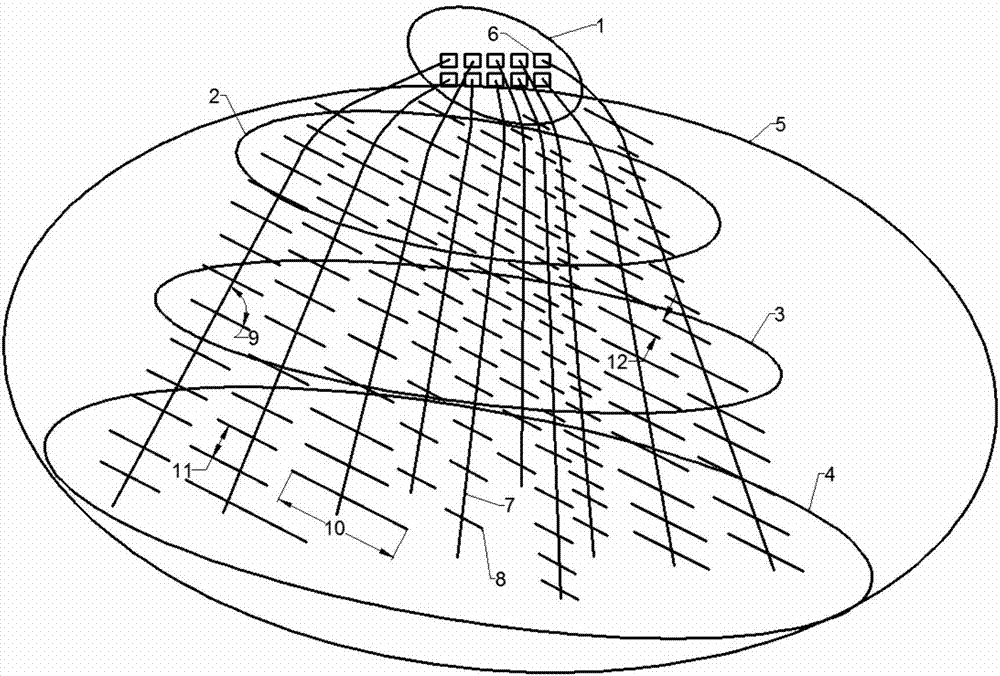

[0020] For a thick glutenite reservoir, when the angle between the horizontal wellbore and the maximum principal stress is 90°, three well platforms need to be arranged. Through the optimization design of the horizontal well borehole, the angle between the horizontal section of the horizontal well group and the maximum principal stress can be greater than 75°. Form a surface well factory 1, radial well pattern, centralized drilling, centralized fracturing, compared with 30% to 40% less land area, control reserves increased by about 25% to 35%.

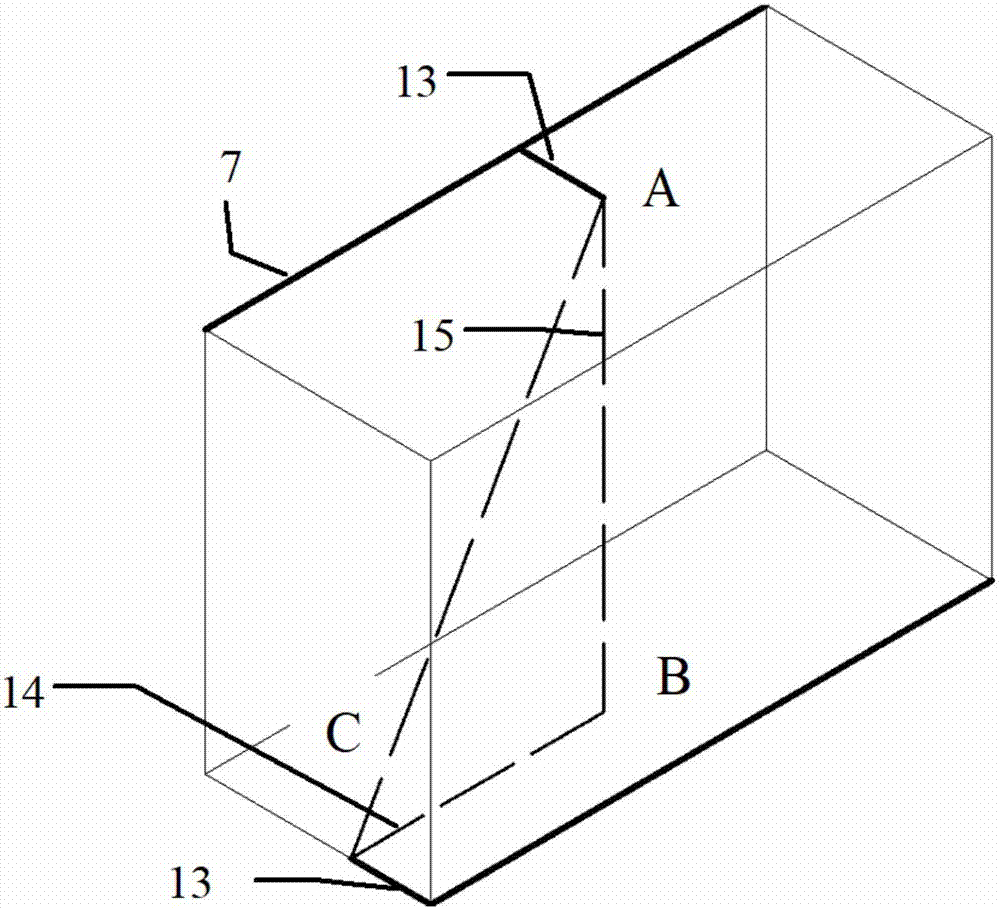

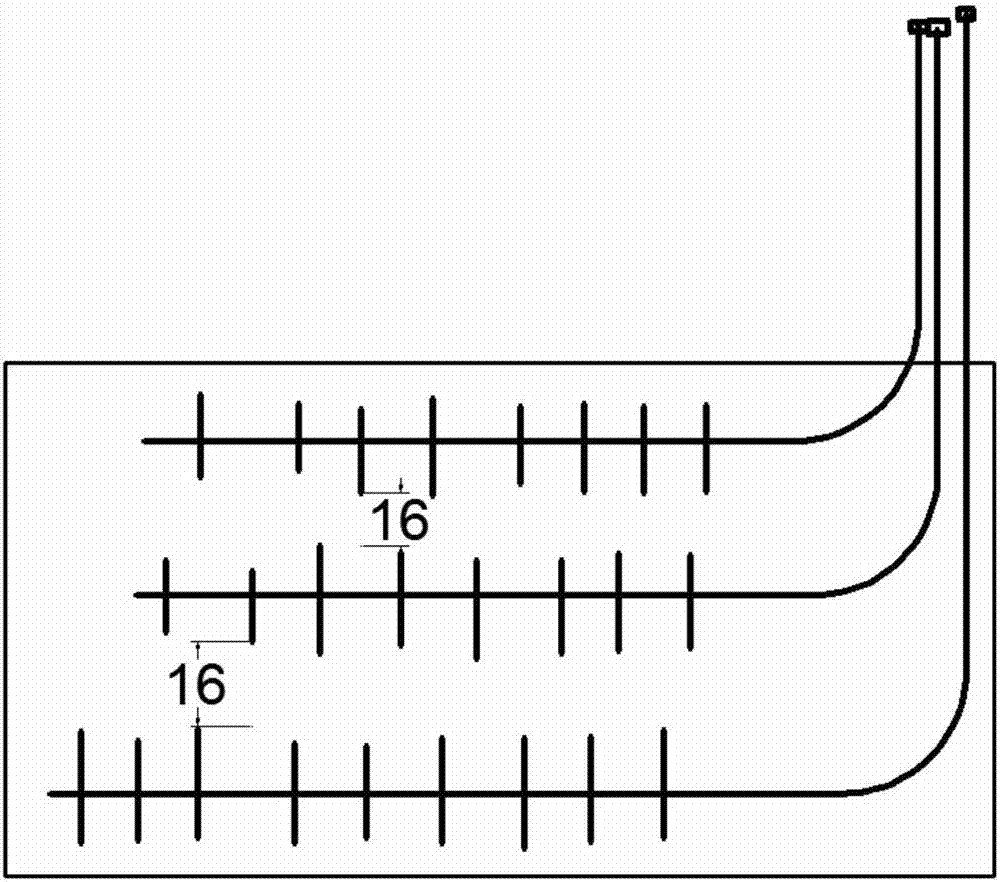

[0021] Using non-Darcy flow theory, the effective flow radius of the reservoir block is calculated to be 34m, and the limit drainage radius is 61m. The reasonable spacing between horizontal wells is determined to be 68-121m. Combined with reservoir characteristics, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com