Combined angle regulator for suspension membrane hollow glass membrane stretching frame

A corner device and combined technology, which is applied in windows/doors, building components, buildings, etc., can solve the problems of affecting the dew point of the inner cavity, cumbersome process, and increased construction difficulty, so as to achieve positioning and installation, convenient construction, and system structure The effect of stability and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

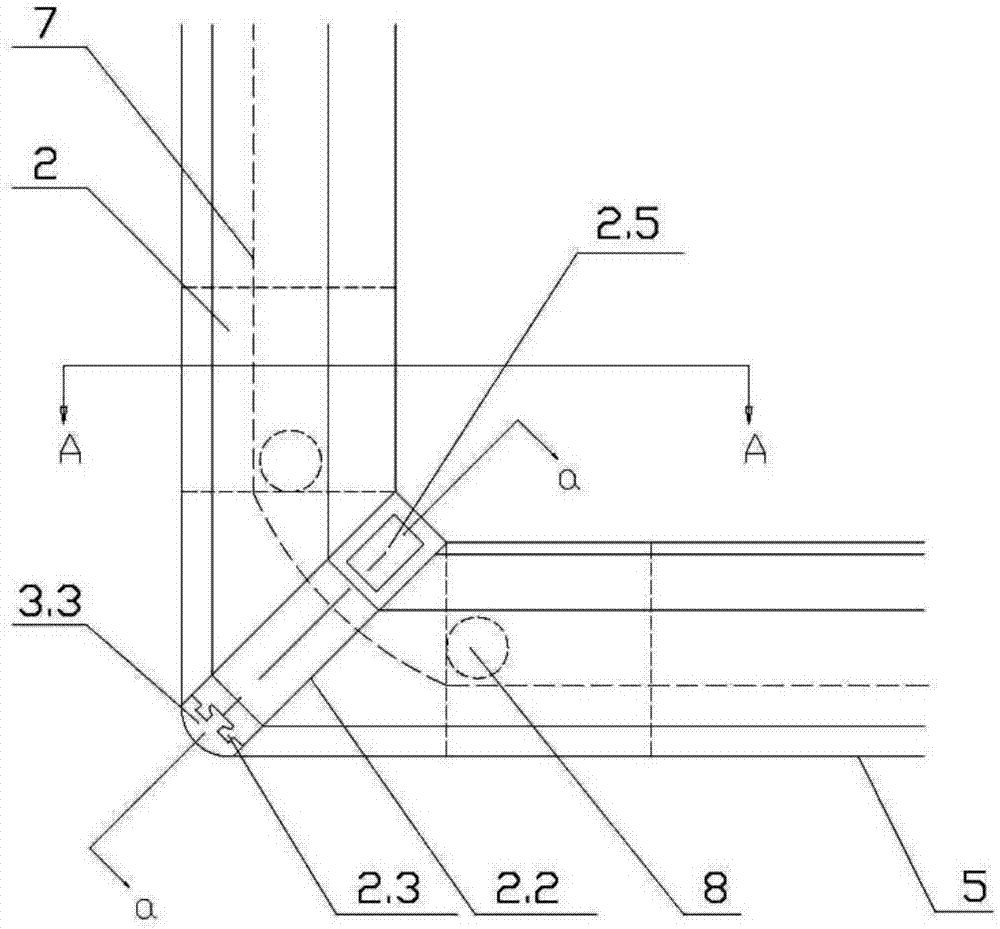

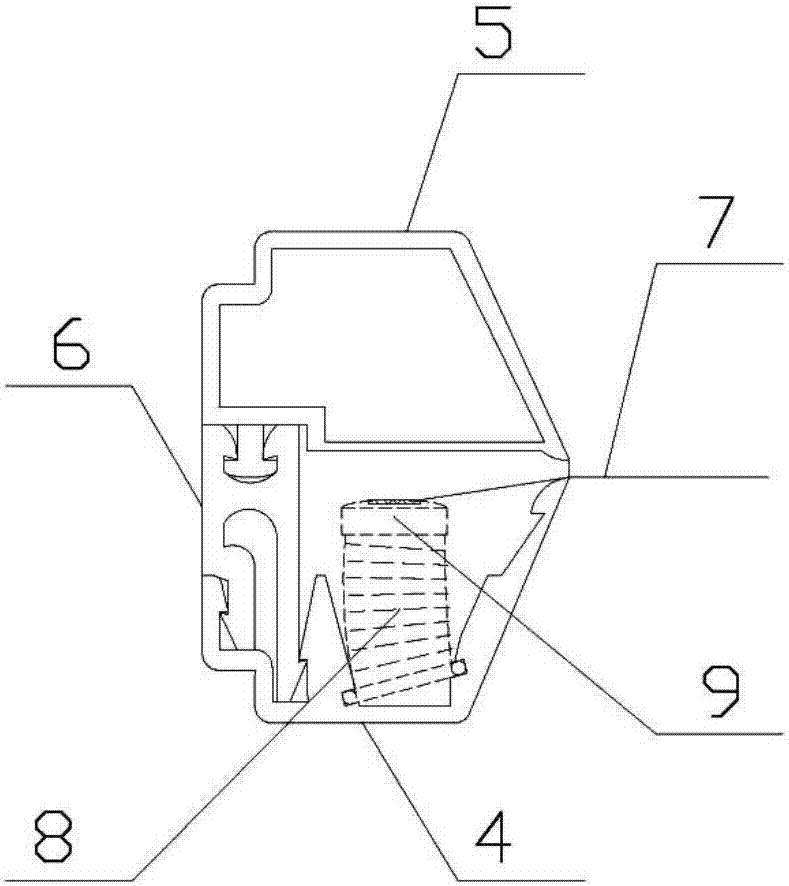

[0044] Such as figure 1 As shown, the suspension film hollow glass structure frame is assembled by the spring frame 4, the drying frame 5 and the spacer 6.

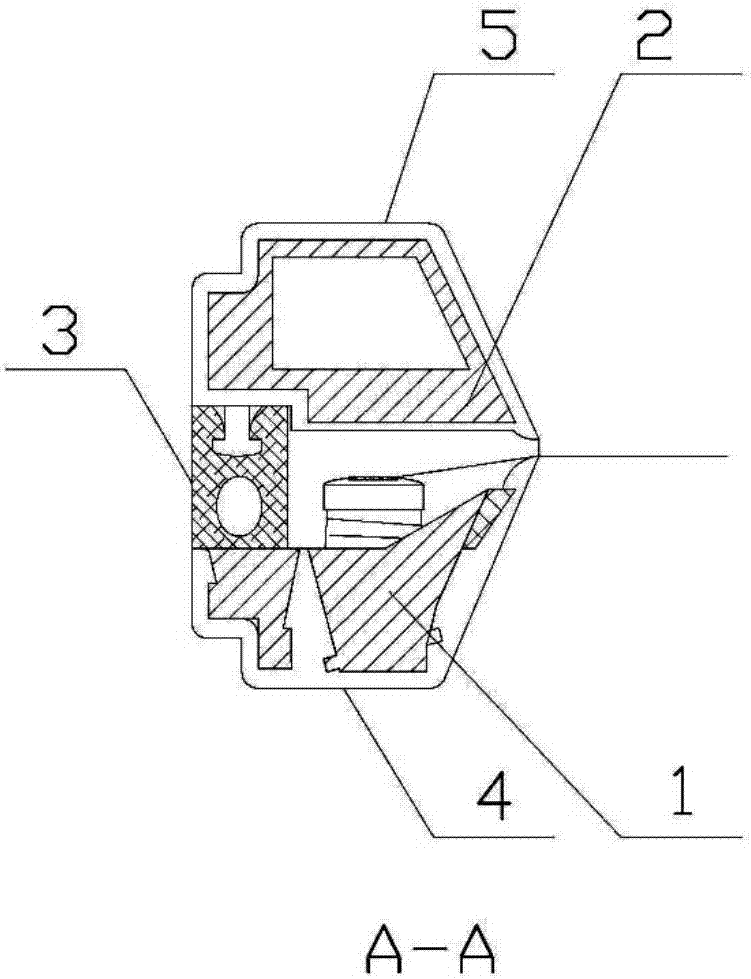

[0045] Such as figure 2 As shown, after the structural frame is connected at the end corner by a combined corner connector, the spring frame 4 is connected to the spring frame pin 1, the drying frame 5 is connected to the drying frame pin 2, and the spacer 6 is connected to the corner connector 3's plug arm 3.1 Docking, the inserting arms 3.1 on both sides are respectively connected to the flange 5.2 of the drying frame 5, and are connected to the pin 1.7 of the spacer slot of the spring frame 4 on a plane.

[0046] Such as image 3 and Figure 4 As shown, after the structural frame is connected at the end corners, the root connected at its outer corner is the bottom plate of the boat-shaped tube 1.2 of the spring frame pin 1 and the boat-shaped tube 2.2 of the drying frame pin 2. The vertical rib plate 3.2 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com