Coal tar deslagging and fraction separation process and device

A separation device and a technology for coal tar, applied in the field of coal chemical industry, can solve the problems of complicated operation, time-consuming, and various waste water generation, etc., and achieve the effects of easy industrialization, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

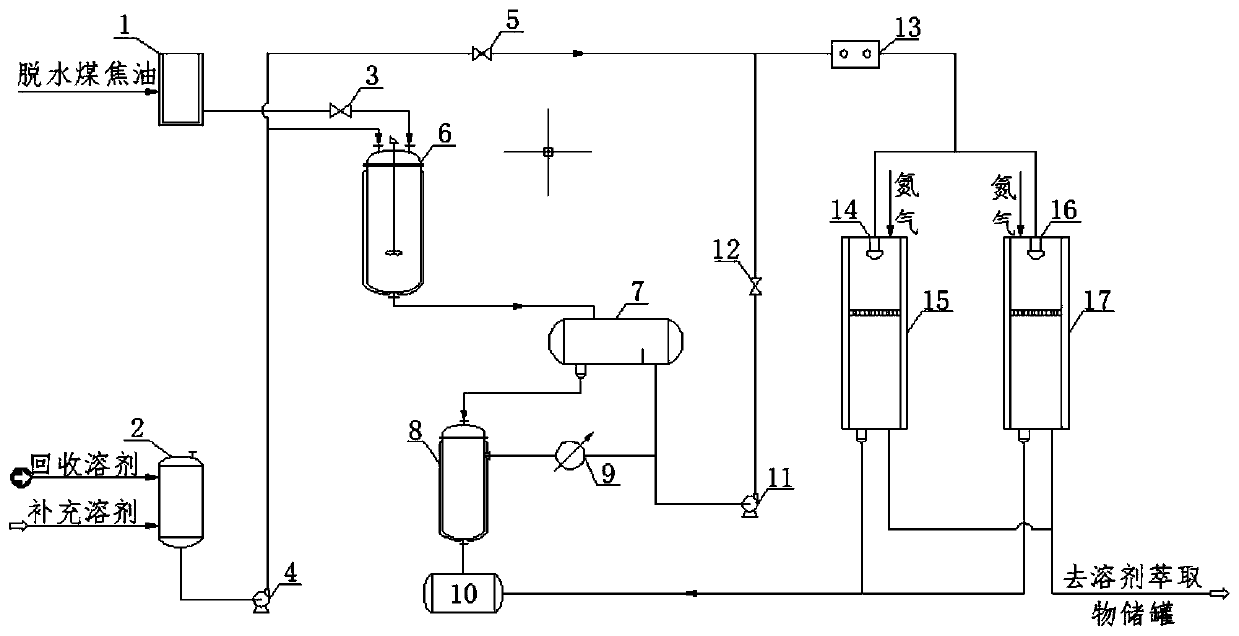

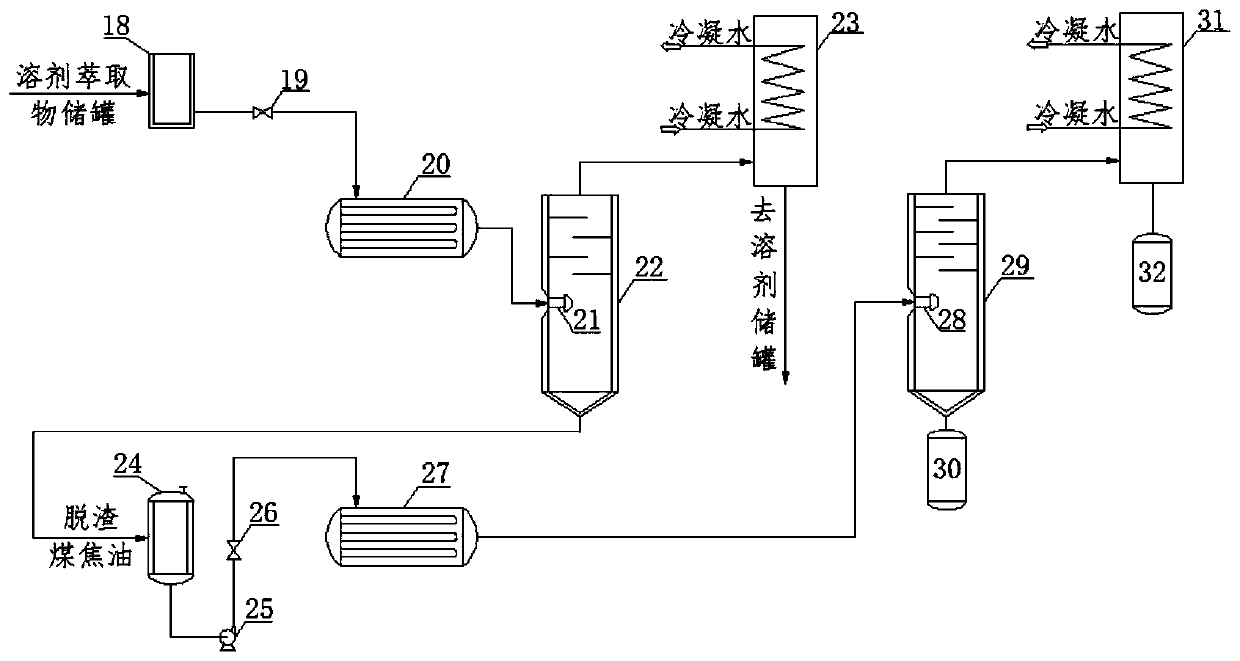

Method used

Image

Examples

Embodiment 1

[0085] Take 200g of dehydrated coal tar and add tetrahydrofuran solvent in a volume ratio of 1:1, stir evenly with a glass rod, remove the tar residue by suction filtration and centrifugation, volatilize a small amount of solvent in the filter paper and the tar residue in the centrifuge tube, and weigh it The calculated slag removal rate (relative to the amount of dehydrated coal tar) is 0.12%. Then take 200g of dehydrated coal tar and tetrahydrofuran solvent in a volume ratio of 1:1 and add it to the coal tar extraction reaction kettle of the device, carry out the test according to the above procedure, weigh the tar residue stored in the tar residue storage tank and calculate the deslagging The ratio (relative to the amount of dehydrated coal tar) was 0.3%.

[0086] To sum up, it can be seen that the deslagging of coal tar by this device is more thorough than that of laboratory deslagging, and there will be no loss due to solvent volatilization.

Embodiment 2

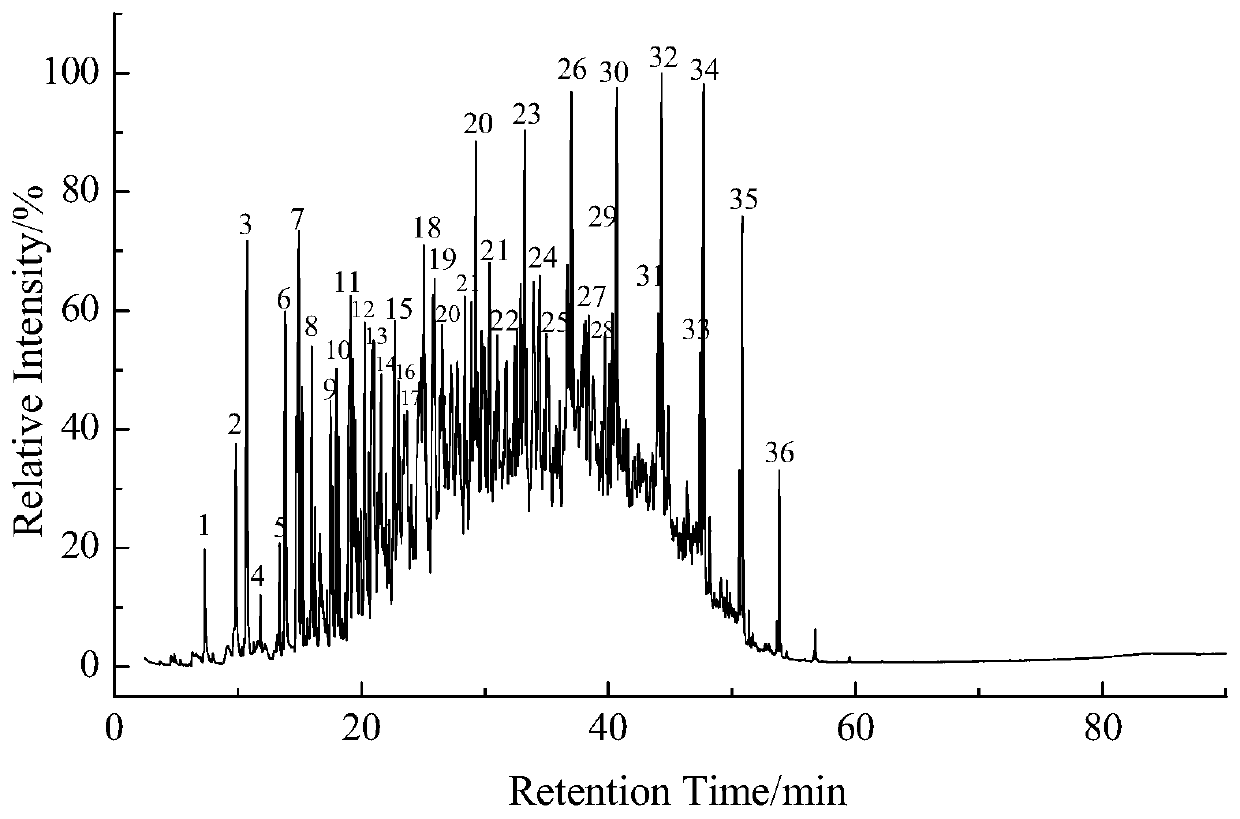

[0088] A certain amount of dehydrated coal tar was tested according to the aforementioned process, and the temperature of the second tubular preheater was set to 200°C and 300°C respectively. ≥200°C fraction), heavy 1 (≤200°C fraction), light 2 (≥300°C fraction), heavy 2 (≤300°C fraction) each 1mL, then dissolved in 2mL of dichloromethane, and then GC-MS and TG analysis, analysis results see image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8, Figure 9 , Figure 10 And Table 2, Table 3, Table 4 and Table 5.

[0089] Take a certain amount of dehydrated coal tar into the device, after deslagging and desolventization, the deslagging coal tar is preheated to 200°C in the second tubular preheater, and cut in the decompressed state of the second decompression vaporization chamber. Fractions, light 1 (fraction ≤ 200°C) and heavy 1 (fraction ≥ 200°C) of medium and low temperature coal tar were obtained, detected by GC-MS and TG, and the analysis results were as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com