A self-disturbing capsule solid foaming agent

A bubble-discharging agent and capsule-like technology, which is applied in the field of self-disturbing capsule-shaped solid bubble-discharging agent, can solve the problems of inability to achieve self-disturbance, low foaming ability of bubble-discharging rods, and small scope of foam-discharging agent, etc. Increased, increased reaction rate, economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

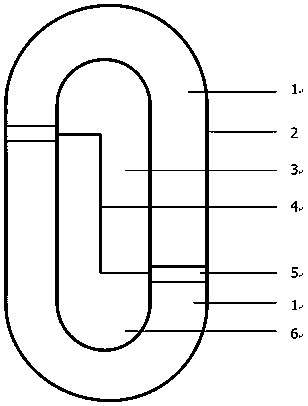

[0011] The structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The composition and mass percentage of the capsule shell of the self-disturbing capsule-shaped solid foaming agent are as follows: 35% sodium dodecylsulfonate, 25% fatty alcohol polyoxyethylene ether, 10% acrylic resin, 8% sodium bicarbonate, 5% urea %, citric acid 15%, hydroxyethyl cellulose 2%. The solid foaming agent is compacted to increase the density to achieve the sealing effect. The capsule shell has an appearance length of 50mm, a hemisphere with an outer diameter of 25mm at both ends, a cylinder with a diameter of 25mm in the middle, and a thickness of the interlayer of 4mm. The diameter of the two symmetrical small holes is 2mm, and the distance between the center of the small hole and the edge of the hemisphere and the cylinder is 2mm.

[0013] The components and ingredients of the liquid foaming agent in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com