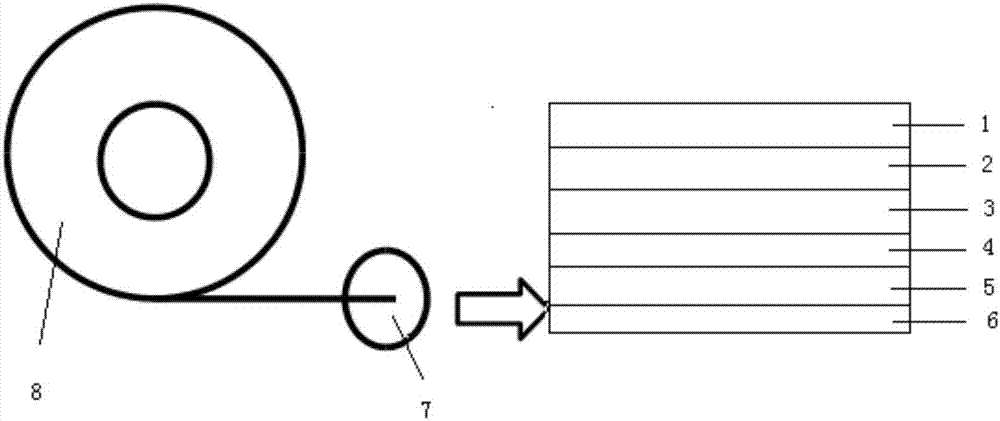

Super-resilient PU foam double-sided adhesive tape and manufacturing method thereof

A technology of double-sided tape and resilience, which is applied in the direction of adhesives, film/sheet adhesives, pressure-sensitive films/sheets, etc., and can solve the problem of foam double-sided tape's general stickiness and comprehensive performance, and poor surface adhesion , easy to residual glue and other problems, to achieve the effect of excellent holding force, good adhesion, and not easy to residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The foam base material is 1mm thick polyester PU foam base material 3

[0023] The first step is to corona treat one side of the PU foam with a voltage of 3000 volts, and the treatment gap is 1.5mm;

[0024] The second step is to corona treat the second side of the PU foam with the same voltage and treatment gap;

[0025] In the third step, primer 2 is applied to one side of the substrate with a coating amount of 50 g / square meter;

[0026] The fourth step is to evenly brush the treated pressure-sensitive adhesive on the first surface with a coating amount of 80 g / m2;

[0027] The 5th step, with the coating amount of 50 grams / square meter, primer is applied on the second surface of the substrate;

[0028] The sixth step is to evenly brush the treated pressure-sensitive adhesive on the second surface with a coating amount of 80 g / m2, and dry the pressure-sensitive adhesive layer at a temperature of 80°C-110°C for 2-3 minutes ;

[0029] The seventh step is to attach t...

Embodiment 2

[0032] The foam base material is 3mm thick polyester PU foam base material

[0033] The first step is to corona treat one side of the PU foam with a voltage of 5000 volts, and the treatment gap is 1.5mm;

[0034] The second step is to corona treat the second side of the PU foam with the same voltage and treatment gap;

[0035] In the third step, primer is applied to one side of the substrate with a coating amount of 40 grams per square meter;

[0036] The fourth step is to evenly brush the treated pressure-sensitive adhesive on the first surface with a coating amount of 80 g / m2;

[0037] The 5th step, with the coating amount of 40 grams / square meter, primer is applied on the second surface of the substrate;

[0038] The sixth step is to evenly brush the treated pressure-sensitive adhesive on the second surface with a coating amount of 80 g / m2, and dry the pressure-sensitive adhesive layer at a temperature of 80°C-110°C for 3-5 minutes ;

[0039] The seventh step is to atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com