Carbon-fibre composite as well as preparation method thereof and radar antenna using carbon-fibre composite

A composite material and radar antenna technology, which is applied in the field of radar communication, can solve the problems that the radar antenna cannot meet the application requirements of modern airport monitoring, the adverse impact of airport surface control security, and the slow scanning speed of the radar antenna, so as to ensure the high reliability of the whole machine. performance, improve work reliability, and ensure the effect of fixed connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

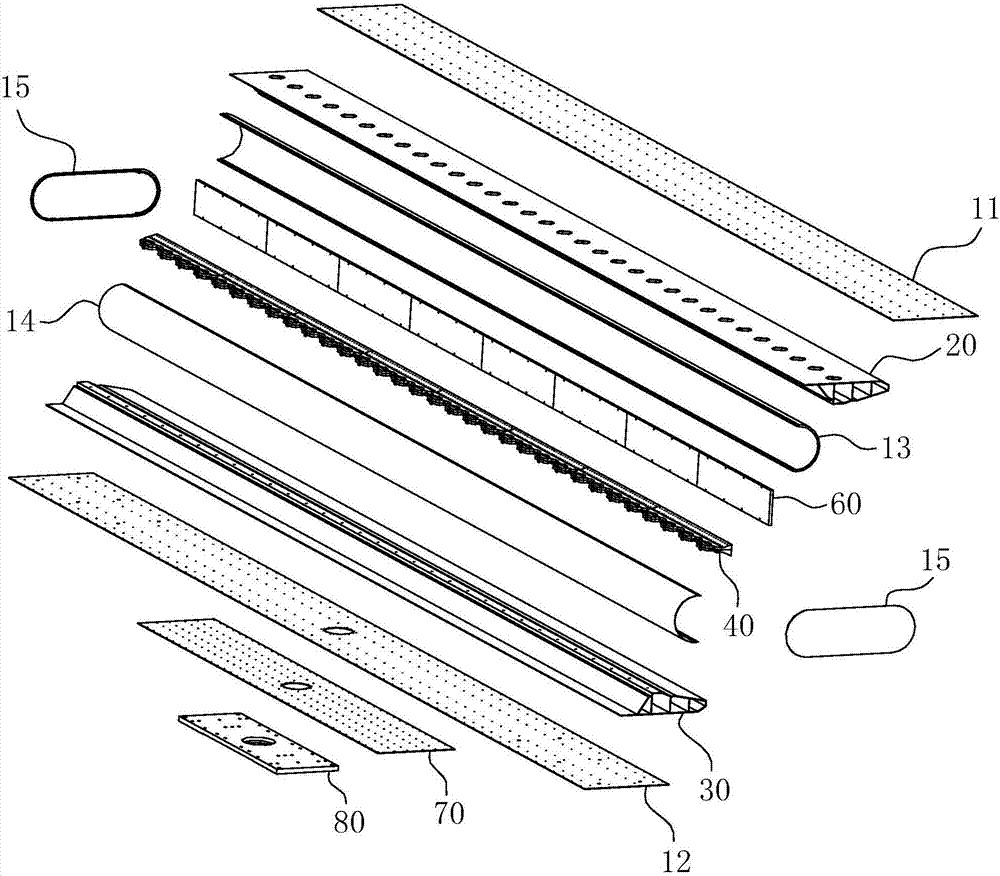

[0034]The carbon fiber composite material of the present invention is made up of epoxy resin and high-strength carbon fiber; The weight percentage of each component is calculated by 100%, and the weight percentage of high-strength carbon fiber is 60%~70%, and the weight percentage of epoxy resin is 30%-40%; wherein, the high-strength carbon fiber is a continuous filament carbon fiber treated with polyacrylonitrile. In the epoxy resin, the latent amine curing agent accounts for 5-10% of the total amount of the epoxy resin; that is, if the total amount of the epoxy resin is 100 parts, the latent amine curing agent accounts for 5-10 parts. During specific preparation, its preparation method comprises the following steps:

[0035] 1), take raw material according to above-mentioned each percentage by weight;

[0036] 2) Adopt dry molding process to obtain uniform glue-containing prepreg made of epoxy resin;

[0037] 2) Lay the prepreg and high-strength carbon fiber layer by layer...

Embodiment 1

[0041] 1), based on the weight of each component and calculated by 100%, the weight percentage of the high-strength carbon fiber is 60%, and the weight percentage of the epoxy resin is 40%; wherein, the high-strength carbon fiber is polypropylene Continuous filament carbon fiber treated with nitrile; in the epoxy resin, the latent amine curing agent accounts for 5% of the total amount of the epoxy resin. During specific preparation, its preparation method comprises the following steps:

[0042] 2) Adopt dry molding process to obtain uniform glue-containing prepreg made of epoxy resin;

[0043] 2) Lay the prepreg and high-strength carbon fiber layer by layer on the surface of the mold cavity in the form of a layer of prepreg and a layer of high-strength carbon fiber; when laying, pay attention to the different orientations of the parts. Pre-design the laying direction of the high-strength carbon fiber layer;

[0044] 3) Put the mold treated in step 2) into an oven, heat-prese...

Embodiment 2

[0046] 1), based on the weight of each component and calculated by 100%, the weight percentage of the high-strength carbon fiber is 70%, and the weight percentage of the epoxy resin is 30%; wherein, the high-strength carbon fiber is polypropylene Continuous filament carbon fiber treated with nitrile; in the epoxy resin, the latent amine curing agent accounts for 10% of the total amount of the epoxy resin. During specific preparation, its preparation method comprises the following steps:

[0047] 2) Adopt dry molding process to obtain uniform glue-containing prepreg made of epoxy resin;

[0048] 2) Lay the prepreg and high-strength carbon fiber layer by layer on the surface of the mold cavity in the form of a layer of prepreg and a layer of high-strength carbon fiber; when laying, pay attention to the different orientations of the parts. Pre-design the laying direction of the high-strength carbon fiber layer;

[0049] 3) Put the mold treated in step 2) into an oven, heat-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com