Laser fused deposition modeling device and running method thereof

A technology of deposition modeling and laser melting, which is applied in the field of additive manufacturing 3D printing, can solve problems such as nozzle clogging, achieve the effect of small heat-affected zone, speed up molding speed, and speed up molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

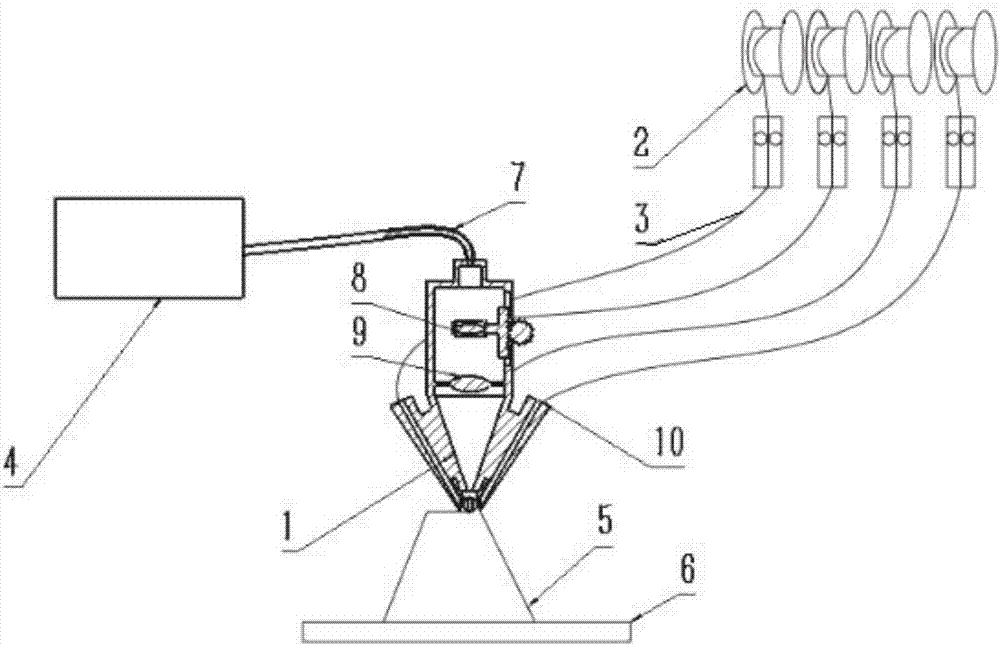

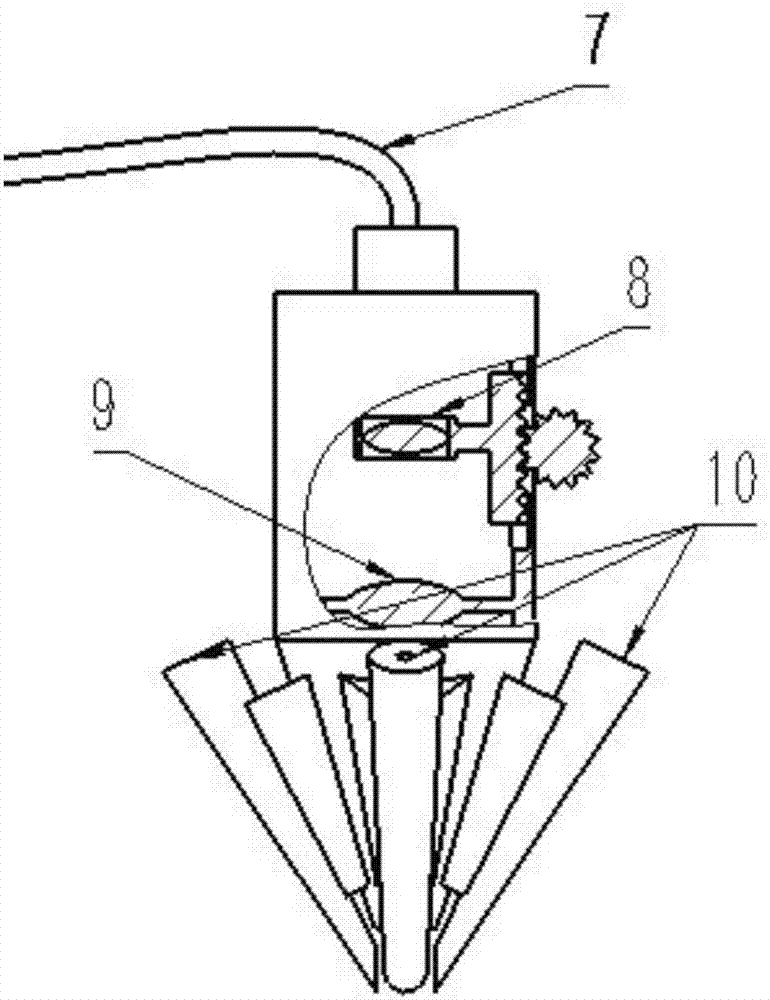

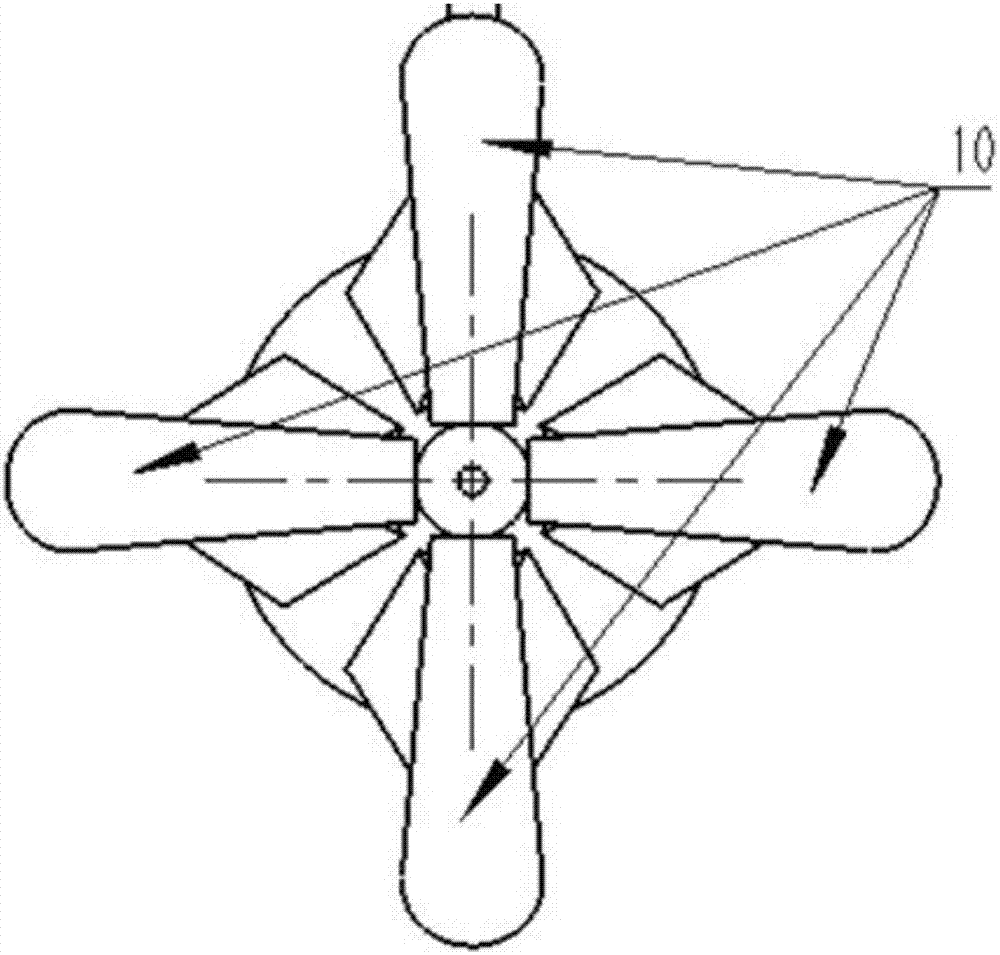

[0026] Such as Figures 1 to 4 shown. The invention discloses a laser fusion deposition molding device, which comprises a carbon dioxide laser generator 4, a composite printing head 1, a multi-channel wire feeding mechanism 2, and a heating bed 6; the interior of the composite printing head 1 is a cavity, from top to bottom A moving lens group 8 and a focusing lens 9 are provided; the carbon dioxide laser generator 4 is connected to the composite printing head 1 through an optical fiber 7, and forms an optical path connection with the moving lens group 8 and the focusing lens 9 in it; the composite printing head 1 The lower end is a conical structure, and a plurality of wire guide channels 10 are distributed along the outer peripheral wall of the conical structure; the wire 3 (consumable material) from the multi-channel wire feeding mechanism 2 penetrates into the wire guide channel 10; the conical structure ensures The wires output by each wire guide channel 10 are gathered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com