Hydraulic forming device with multipoint female groove, and method for manufacturing panel parts through using hydraulic forming device

A technology of hydraulic bulging and sheet metal, which is applied in the field of sheet processing equipment, hydroforming equipment, and sheet metal parts manufacturing. It can solve the problems of long manufacturing cycle, reduce flange parts, sheet metal blanks, and sheet damage, and save high costs. , Shorten the production cycle and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

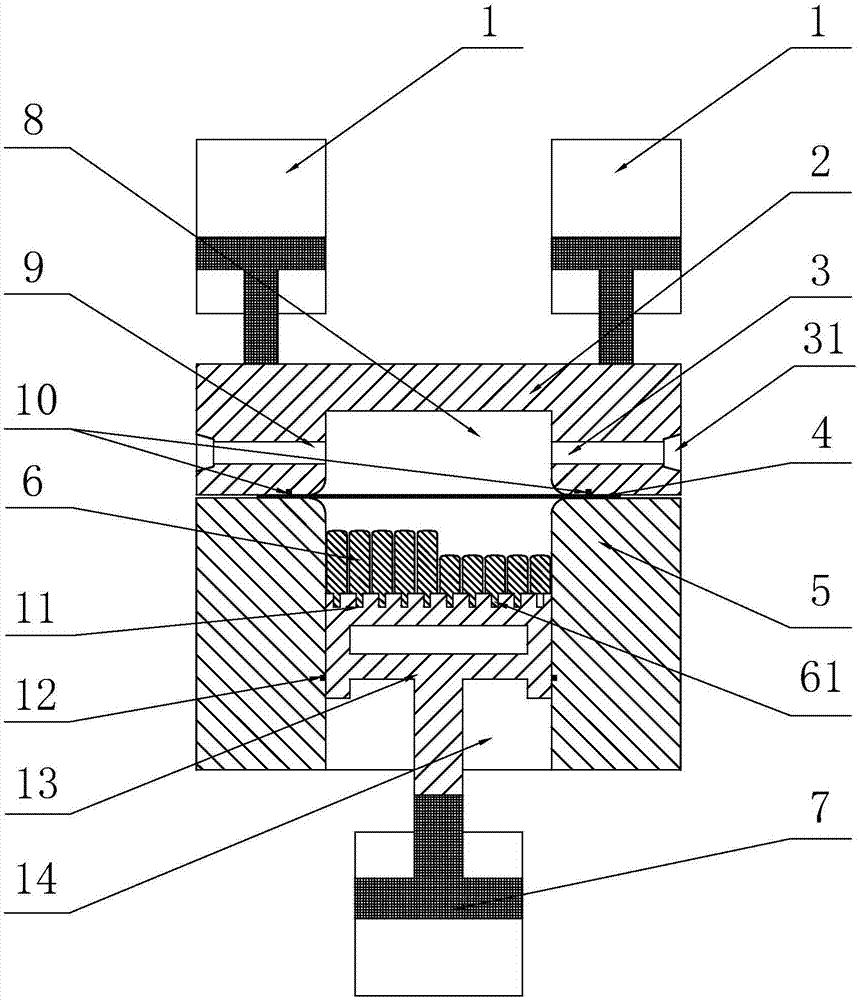

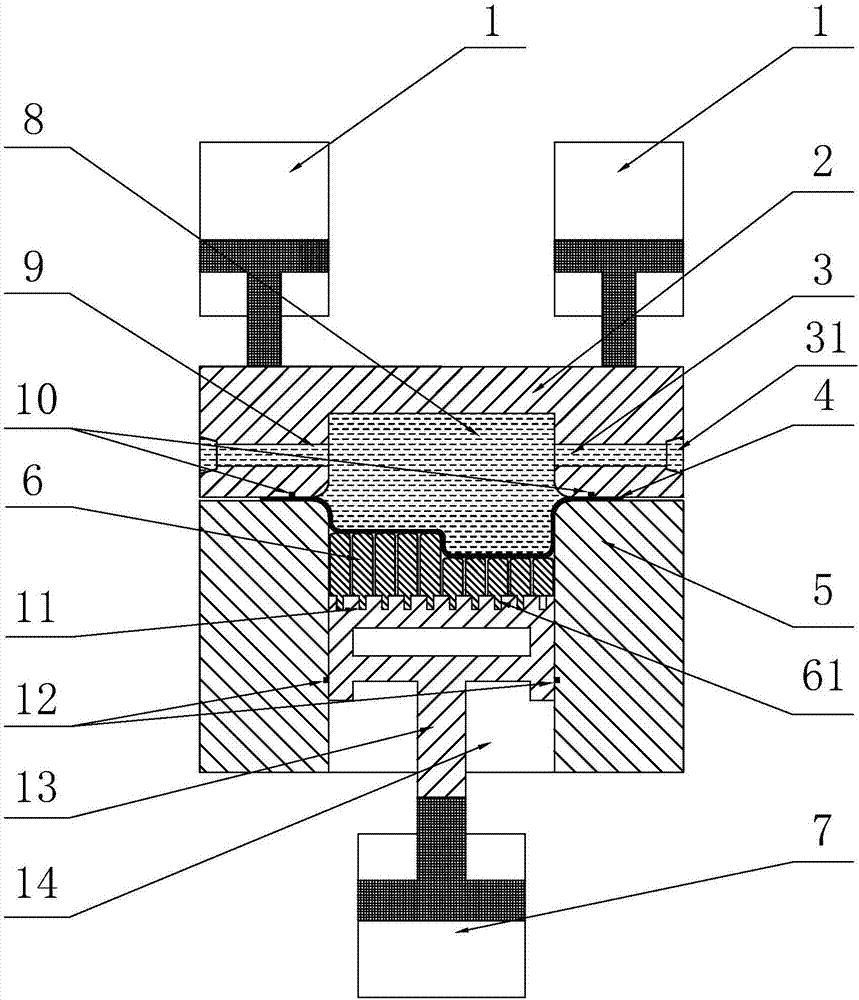

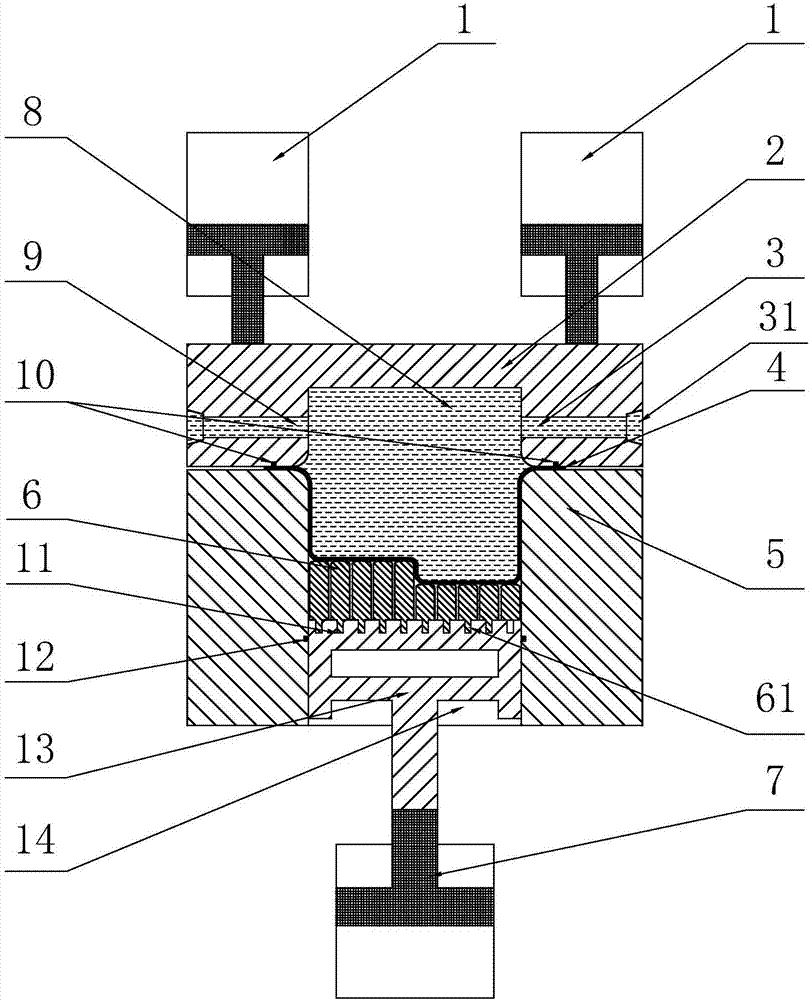

[0032] A sheet metal hydraulic bulging device with a multi-point die, comprising an upper mold 2 and a lower mold 5, the upper mold is connected to a blank holder cylinder 1, the lower mold is installed on a machine base, and the inner cavity of the lower mold is connected to the The cavity corresponding to the shape of the thin-walled deep-cavity plate part to be formed (that is, the cross-sectional shape of the cavity corresponds to the shape of the thin-walled deep-cavity plate part to be formed), and the upper mold is provided with a liquid chamber 8 corresponding to the cavity. The oil inlet channel 9 and the oil outlet channel 3 respectively located on both sides of the upper mold are connected, and the cross-sectional size of the bottom opening of the liquid chamber is consistent with the cross-sectional size of the cavity. When the upper and lower molds are closed, the opening of the liquid chamber is opposite to the cavity;

[0033] The bottom of the lower mold cavity ...

Embodiment 2

[0037] A method for making a deep-cavity plate part, the method is a method for making a thin-walled deep-cavity plate part using the plate hydraulic bulging device with a multi-point die described in Embodiment 1, comprising the following steps:

[0038] S1. Install the sheet blank: place the sheet blank 4 between the upper mold 2 and the lower mold 5, start the blank holder cylinder 1 to apply a blankholder force to the upper mold to clamp the sheet blank;

[0039]S2. Install the multi-point die: according to the shape of the bottom surface of the deep cavity plate parts, select small punches of different or the same height, and install them in the positioning holes of the back pressure die through arrangement and combination to form a thin-walled die with the required depth. Multi-point concave mold with consistent bottom surface shape of cavity plate parts;

[0040] S3. Connect the high-pressure oil circuit: the oil inlet channel is connected to the flange through the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com