Light sensation monitoring and control system of plate winding machine and wind power steel pipe pile cylinder winding process applying system

A control system and monitoring system technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easily damaged workpiece surface, single inspection items, measurement environment restrictions, etc., to achieve strong on-site anti-interference ability and image reproduction. The effect of good performance and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention are described below by specific embodiments, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0044] A light sensing monitoring and control system for a plate rolling machine, comprising:

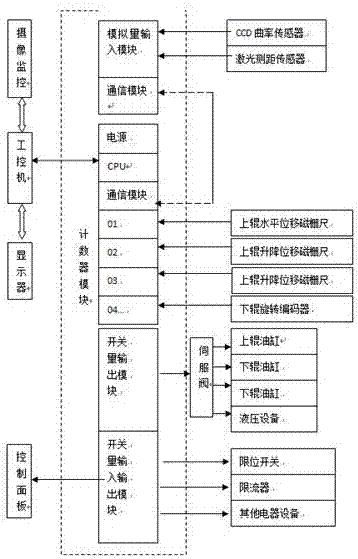

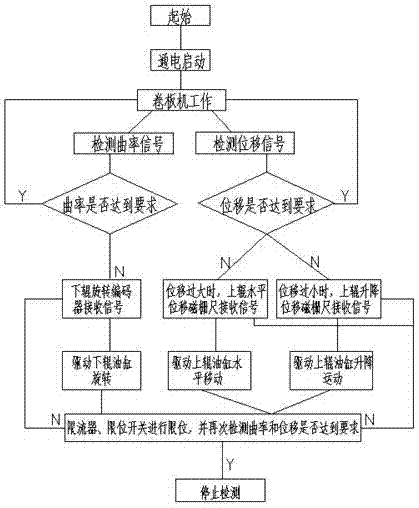

[0045] An online monitoring system, the online monitoring system includes CCD curvature sensor, laser displacement sensor, camera monitoring, upper roll horizontal displacement magnetic scale, upper roll lifting magnetic scale and lower roll rotary encoder;

[0046] A feedback control system, the feedback control system includes a PLC, an industrial computer, a display and a control panel, the PLC includes an analog input module, a communication module, a power module, a counter module, and a switch module, wherein the power module includes a power supply and a CPU, and the counter module includes The counter module 01, the counter modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com