Micro-rolling method for extra-thin variable-thickness strip

A technology of variable thickness and strip, which is applied in the field of strip rolling, can solve the problems that there are still relatively few researches on ultra-thin variable-thickness strip rolling, cannot meet the needs of variable-thickness ultra-thin strips, and cannot achieve thickness, etc. Achieve the effects of improving work efficiency and rolling accuracy, facilitating later data processing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

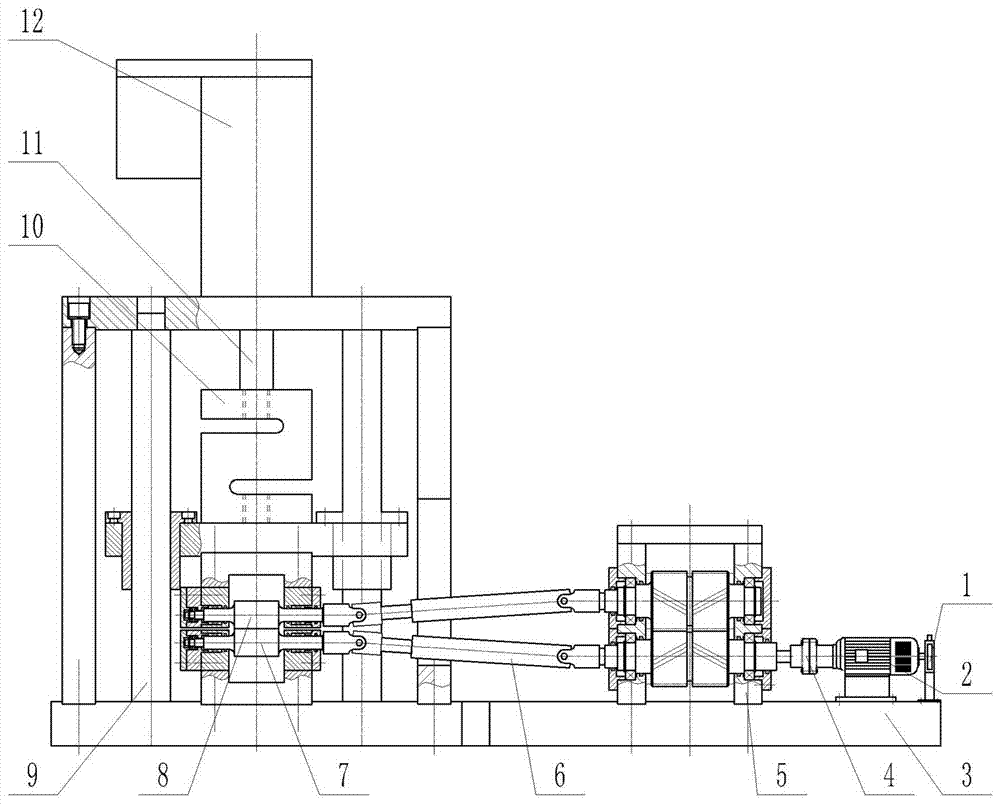

[0038] Embodiment 1: A pure copper strip with a length of 150 mm and a thickness of 0.118 mm was rolled into a thickness of 0.102 mm in the thick zone, a thickness of 0.062 mm in the thin zone, and a length of the transition zone of 4.91 mm.

[0039] The specific operation steps are: (1) Connect all the cables on the rolling mill firmly in turn, and then connect to the power supply.

[0040] (2) Open the back door of the control cabinet, turn on all the motor circuit breaker switches (QF) (“OFF” to “ON” state), then turn the PLC power switch to the “I” state, and turn the CPU switch to the “RUN” state .

[0041] (3) Confirm that the touch screen on the console has been activated successfully and has entered the program interface.

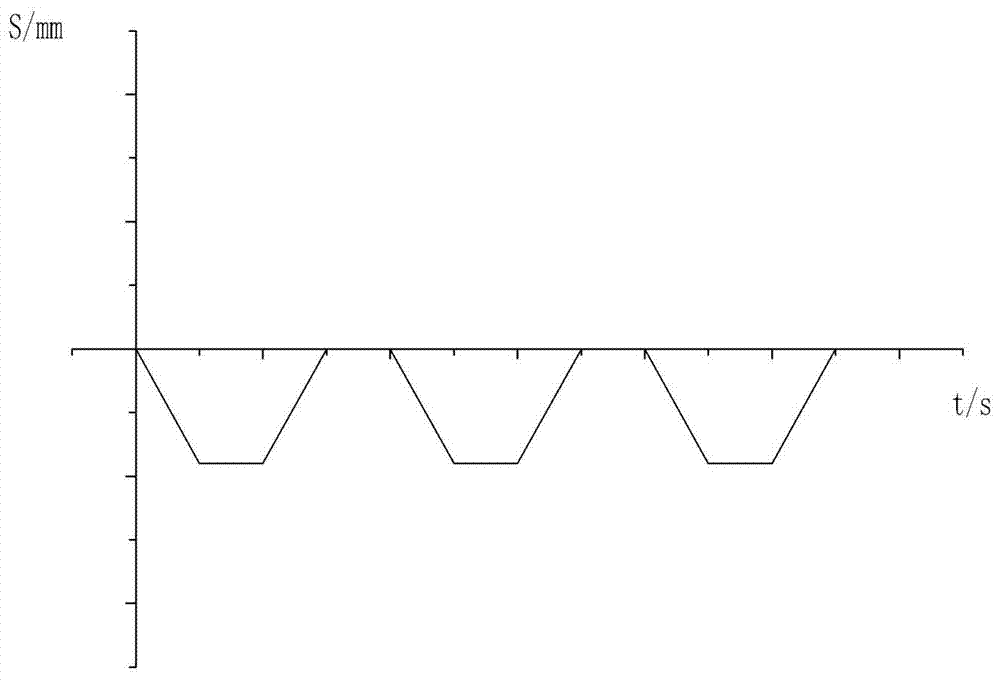

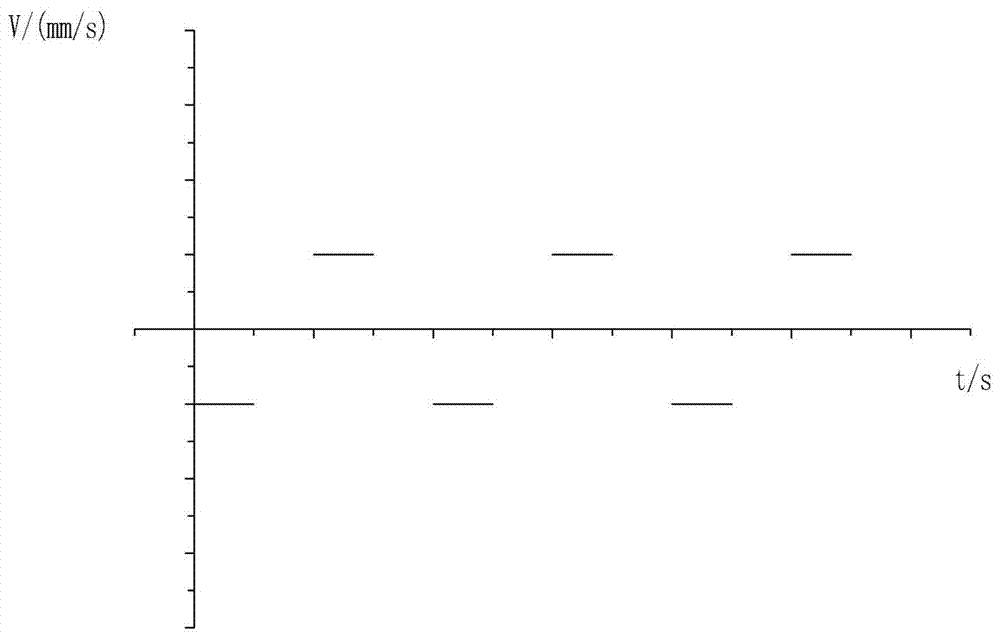

[0042] (4) Enter the variable thickness rolling module and input the rolled thick area H 2 =0.100mm, thick zone length L1=10mm, rolled thin zone H 3 =0.060mm, thin area length L 2 =10mm, transition zone length L 3 =4.90mm, rolling speed paramet...

Embodiment 2

[0048] Embodiment 2: A pure copper strip with a length of 150 mm and a thickness of 0.211 mm is rolled to a thickness of 0.19 mm in a thick zone, a thickness of 0.09 mm in a thin zone, and a length of a transition zone of 6.70 mm.

[0049] The specific operation steps are: (1) Connect all the cables on the rolling mill firmly in turn, and then connect to the power supply.

[0050] (2) Open the back door of the control cabinet, turn on all the motor circuit breaker switches (QF) (“OFF” to “ON” state), then turn the PLC power switch to the “I” state, and turn the CPU switch to the “RUN” state .

[0051] (3) Confirm that the touch screen on the console has been activated successfully and has entered the program interface.

[0052] (4) Enter the variable thickness rolling module and input the rolled thick area H 2 =0.210mm, thick zone length L1=10mm, rolled thin zone H 3 =0.090mm, thin area length L 2 =10mm, transition zone length L 3 =6.50mm, rolling speed parameter 160cm / mi...

Embodiment 3

[0058] Embodiment 3: A pure copper thin strip with a length of 150 mm and a thickness of 0.3 mm was rolled into a thickness of 0.278 mm in the thick area, a thickness of 0.091 mm in the thin area, and a length of 6.72 mm in the transition area.

[0059] The specific operation steps are as follows: (1) Connect all the cables on the rolling mill firmly in turn, and then connect to the power supply.

[0060] (2) Open the back door of the control cabinet, turn on all the motor circuit breaker switches (QF) (“OFF” to “ON” state), then turn the PLC power switch to the “I” state, and turn the CPU switch to the “RUN” state .

[0061] (3) Confirm that the touch screen on the console has been activated successfully and has entered the program interface.

[0062] (4) Enter the variable thickness rolling module and input the rolled thick area H 2 =0.280mm, thick zone length L1=10mm, rolled thin zone H 3 =0.060mm, thin area length L 2 =0.090mm, transition zone length L 3 =6.50mm, roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com