Production equipment of acidic activated nutritive chewing gum and production method of chewing gum

A production equipment and chewing gum technology, which is applied in the field of acid activated nutritional chewing gum production equipment, can solve the problems of poor effect and insufficient mixing of chewing gum raw materials, and achieve the effect of avoiding direct contact and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

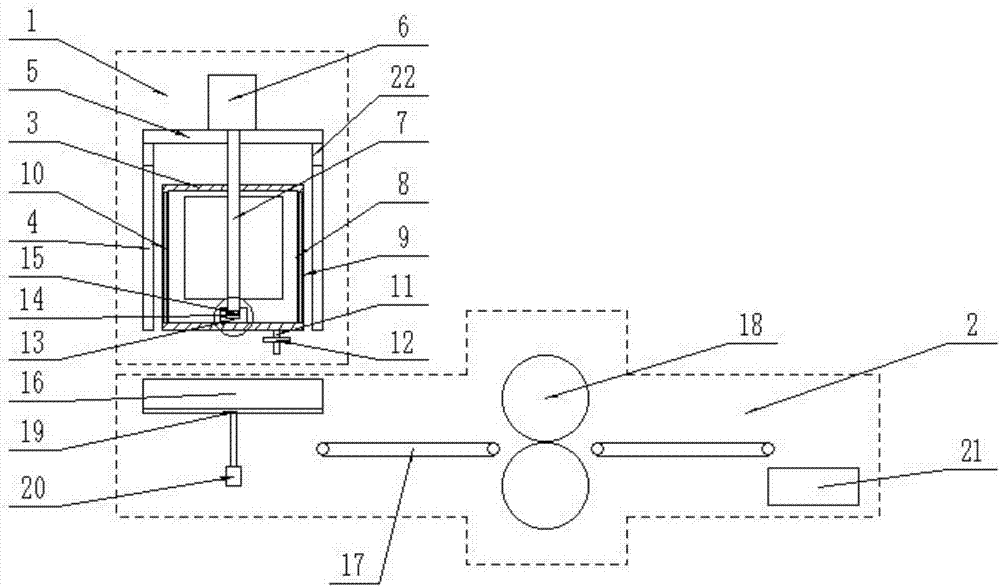

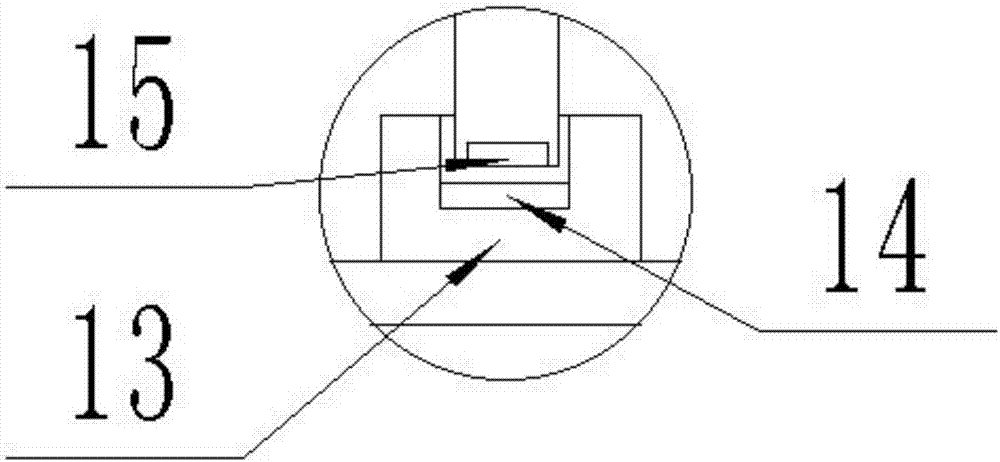

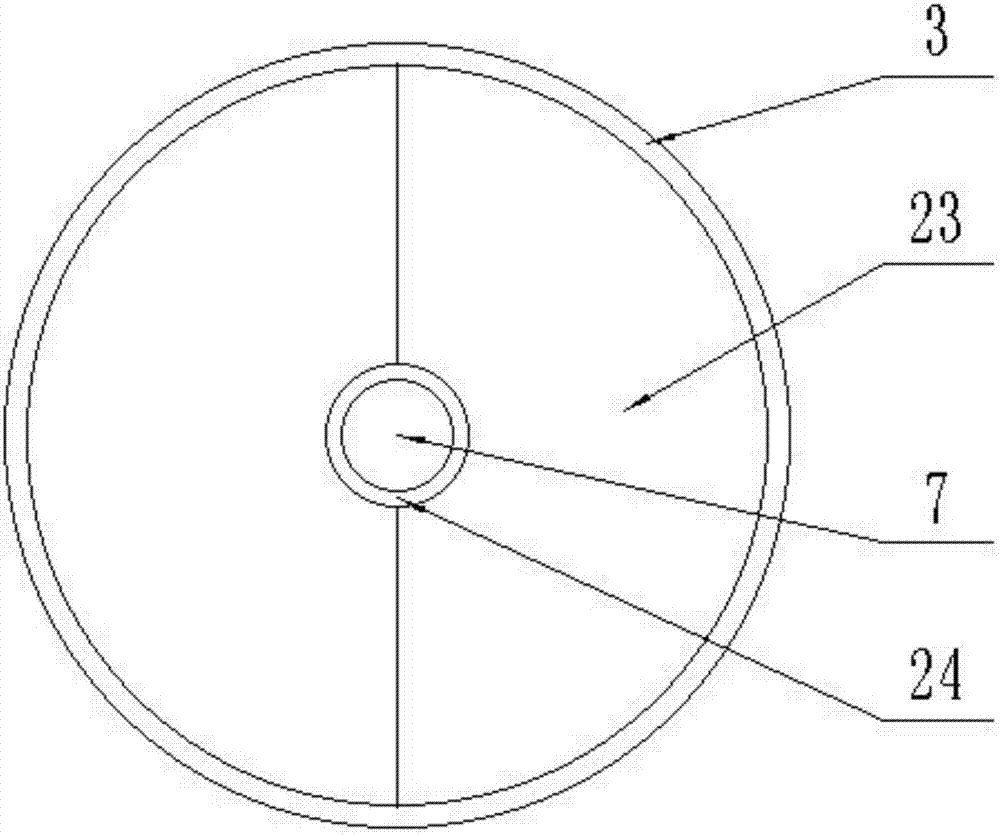

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 Shown, a kind of acid activated nutrition chewing gum production equipment and chewing gum production method, comprise raw material mixing and heating device 1 and cooling and rolling device 2, described raw material mixing and heating device 1 is composed of heating tank 3, four that are arranged on the outside of heating tank 3 The support 4, the stage 5 arranged on the top of the support 4, the motor 6 arranged on the stage 5, and the agitator 7 connected to the rotating end of the motor 6 are composed of an inner wall 8 and an outer wall 9 arranged on the heating tank 3, A heating wire 10 is provided between the inner wall 8 and the outer wall 9, a discharge port 11 is provided at the bottom of the heating tank 3, a solenoid valve 12 is provided at the discharge port 11, and a support is provided on the inner bottom surface of the heating tank 3. Seat 13, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com