A remote monitoring system for biomass pellet machine

A remote monitoring system and biomass particle technology, applied in the general control system, control/regulation system, program control, etc. Temperature rise and other issues, to achieve user-friendly experience, perfect functions, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] The invention relates to a remote monitoring system for a biomass pellet machine, which is suitable for real-time monitoring and real-time alarm maintenance of the existing biomass pellet machine.

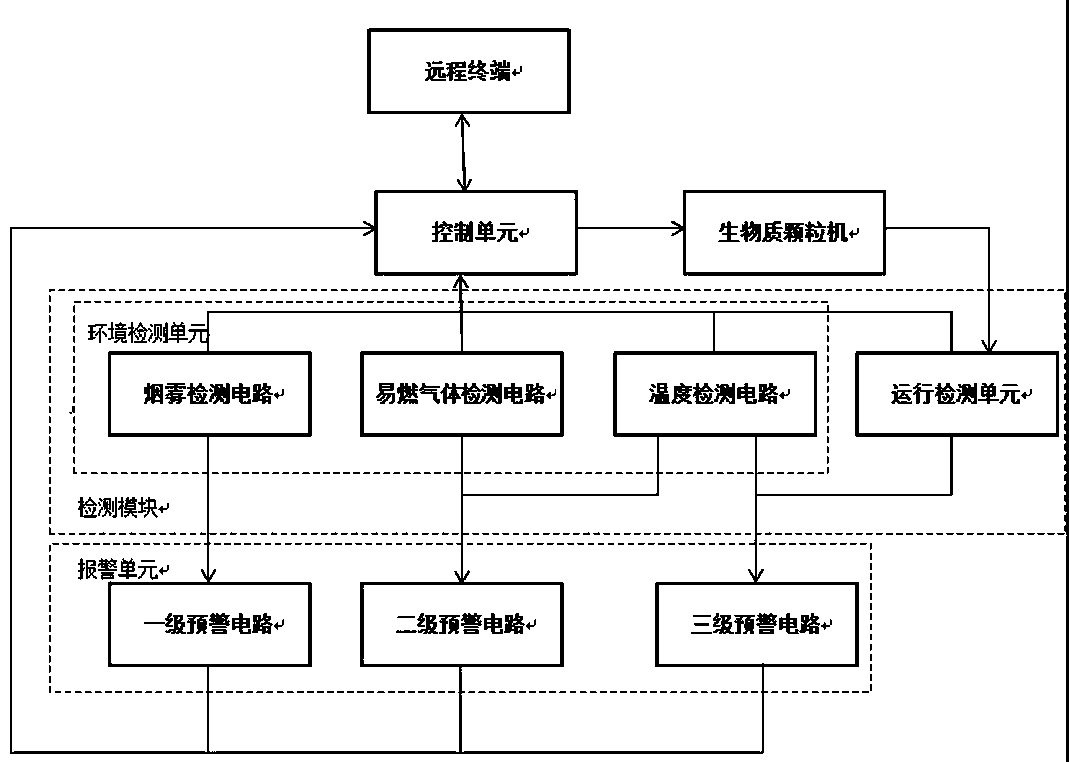

[0036] Such as figure 1 , the system includes a remote terminal, a detection module, and a central processing module. The central processing module collects the real-time signal of the biomass pellet machine through the detection module, and transmits it to the remote terminal through network GPRS communication, wherein the remote terminal can be a PC monitoring terminal , any configuration software is installed on it, and a GRM OPC server is set up, or it can be a cloud server, and the PC monitoring terminal shares information through the cloud server.

[0037] The detection module includes an environmental monitoring unit for detecting the surrounding en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com