Method for evaluating shale gas adsorption through coal/shale ultrahigh pressure gas absorption and seepage experiment

A gas adsorption and ultra-high pressure technology, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, measuring devices, etc. It can solve problems such as deviation, inability to change core water content, and inability to imitate the physical conditions of high-temperature and high-pressure formations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0125] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

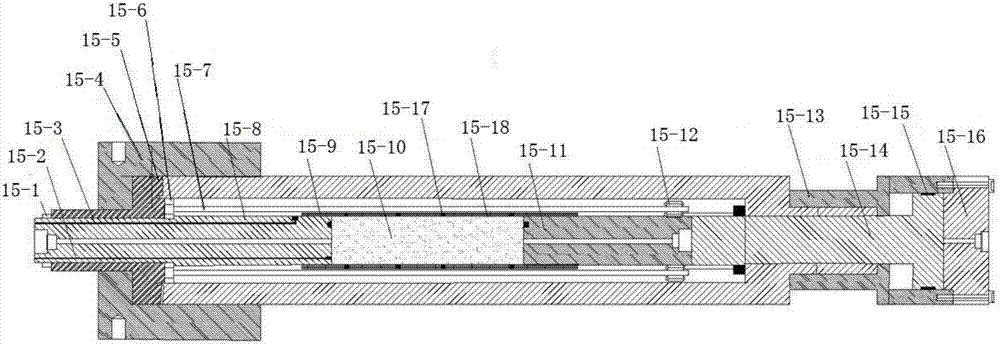

[0126] The present invention realizes multifunctionality, under certain conditions, the permeability of the rock core can be measured, the connection of the device can be changed, and the change of the adsorption amount of the rock core in different states can be measured; it lies in changing different experimental conditions, measuring the adsorption amount of the rock core, thereby establishing different Physical factors, including the water content of the core, temperature, pressure, etc., affect the adsorption capacity.

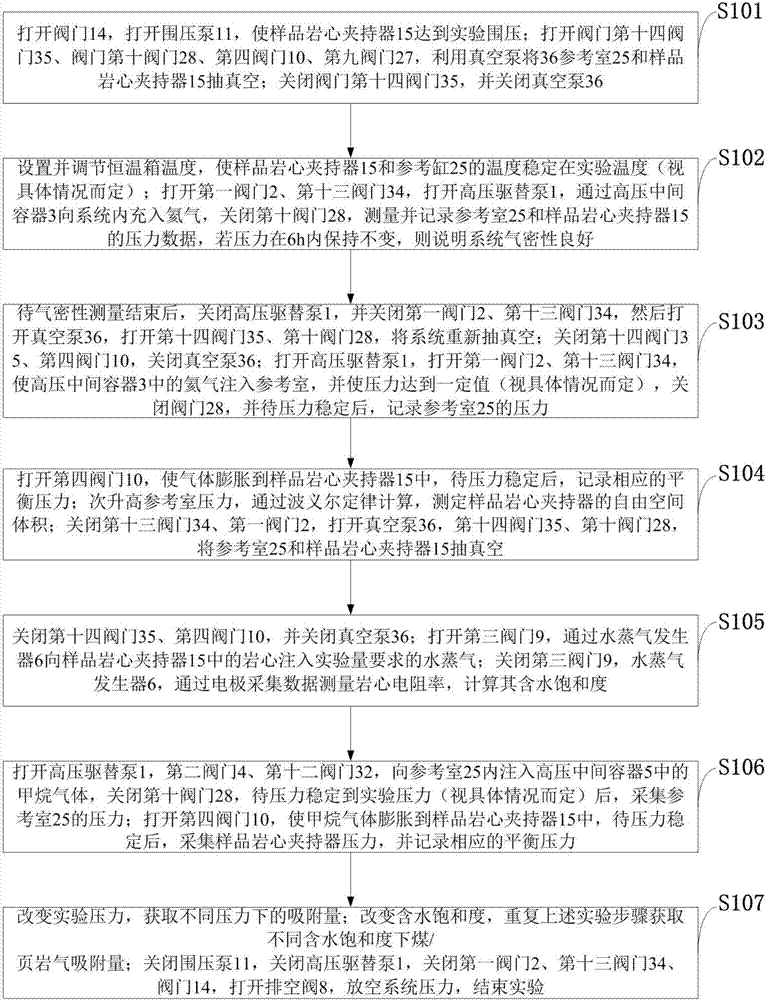

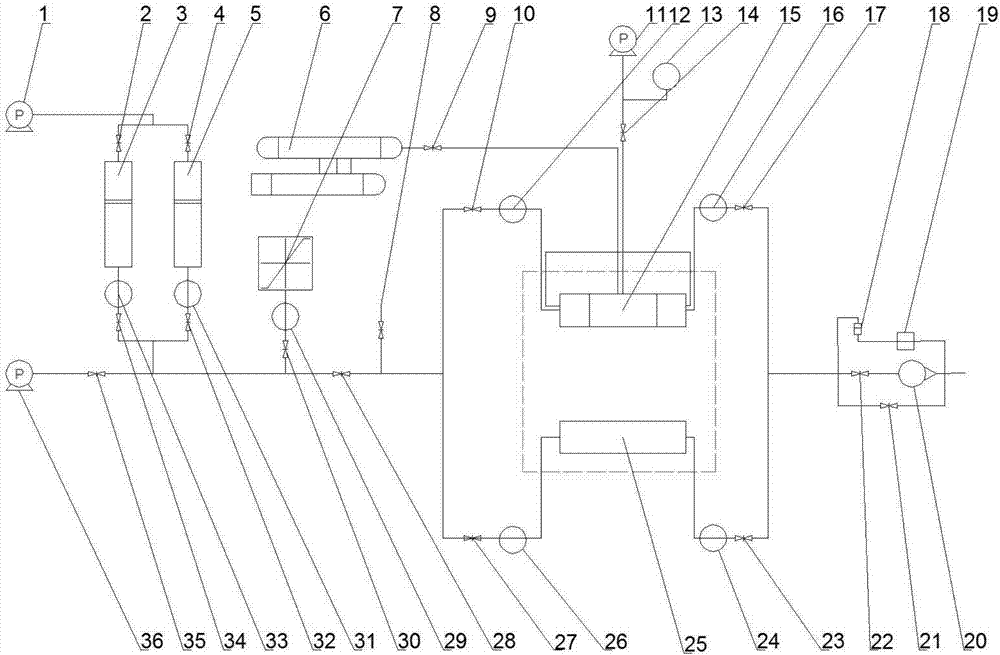

[0127] The application principle of the present invention will be described in detail below in conj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com