Multifunctional chemical pipeline safe cover

A chemical pipeline and multi-functional technology, applied in the direction of pipeline system, pipe components, lighting device parts, etc., can solve the problems of inconvenient disposal, leakage, single function, etc., to achieve easy placement, improved tightness, and better use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

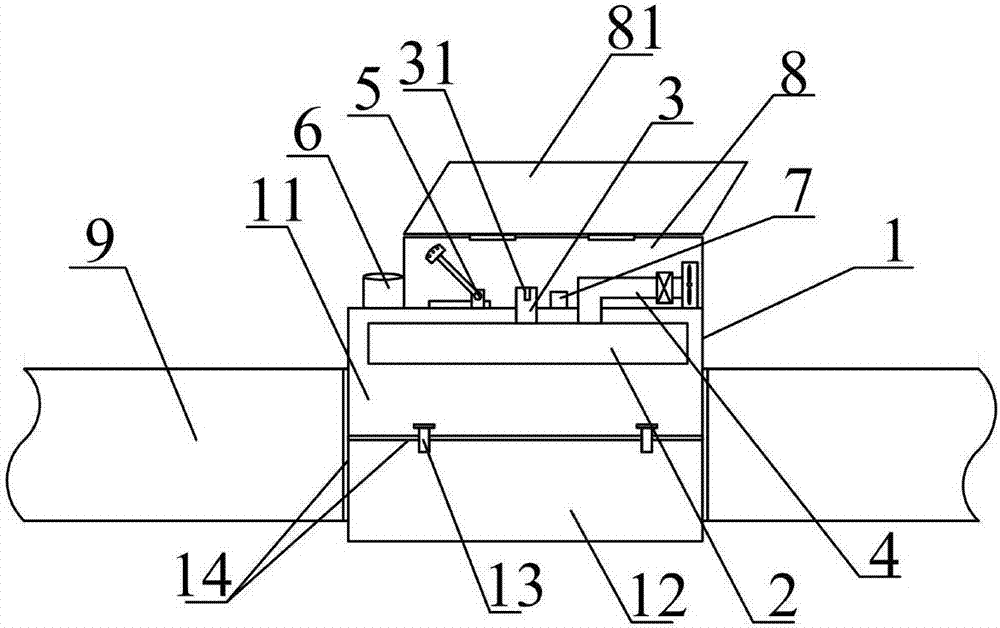

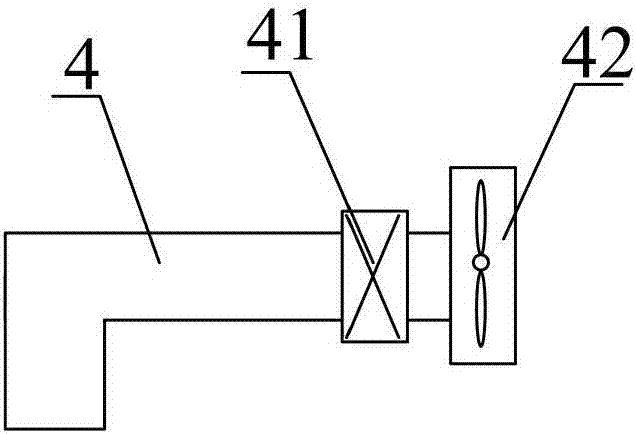

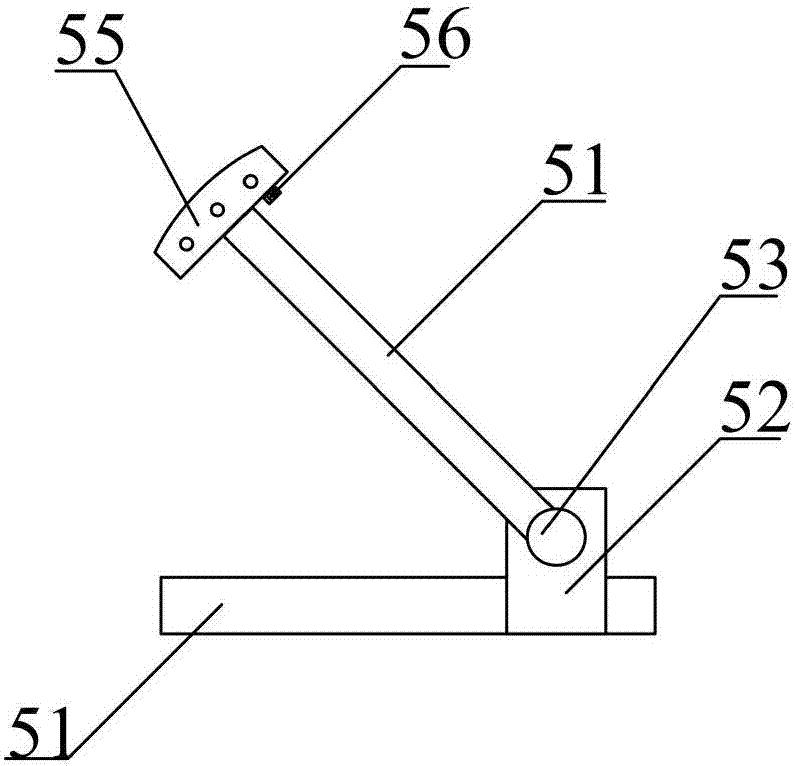

[0032] as attached figure 1 To attach image 3 shown

[0033] The present invention provides a multifunctional chemical pipeline safety cover, comprising a sleeve 1, a cavity 2, a detection tube 3, an exhaust pipe 4, an emergency lighting device 5, an alarm lamp 6 and a control chip 7. The sleeve 1 Sleeved at the joint of the chemical pipeline 9; the cavity 2 is arranged above the inside of the sleeve 1; the detection tube 3 and the exhaust pipe 4 are arranged on the upper part of the sleeve 1 and communicated with the cavity 2; The emergency lighting device 5 is arranged on the left side of the detection tube 3 ; the warning light 6 is arranged on the left side of the emergency lighting device 5 and connected with the control chip 7 .

[0034] In the above embodiment, specifically, the sleeve 1 is divided into an upper sleeve 11 and a lower sleeve 12, the upper sleeve 11 and the lower sleeve 12 are semi-arc tubes, and the upper sleeve 11 and the lower pipe sleeve 12 are fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com