Solenoid coil assembly and solenoid valve

A technology of electromagnetic coils and coil windings, applied in the field of electromagnetic valves, injection valves or fuel injection valves of motor vehicles, can solve the problems of unfavorable automation and inability to realize productivity, and achieve the effect of high production efficiency and reduced structural length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next refer to Figures 1 to 3 and 5 to 13 to describe the embodiment of the present invention in detail. Identical and equivalent and identically or equivalently acting elements and components are identified with the same reference symbols. Detailed descriptions of identified elements and features will not be repeated in every instance in which such elements and features appear.

[0035] The features shown and other properties can be separated from one another and combined with one another in any desired manner without departing from the core of the invention.

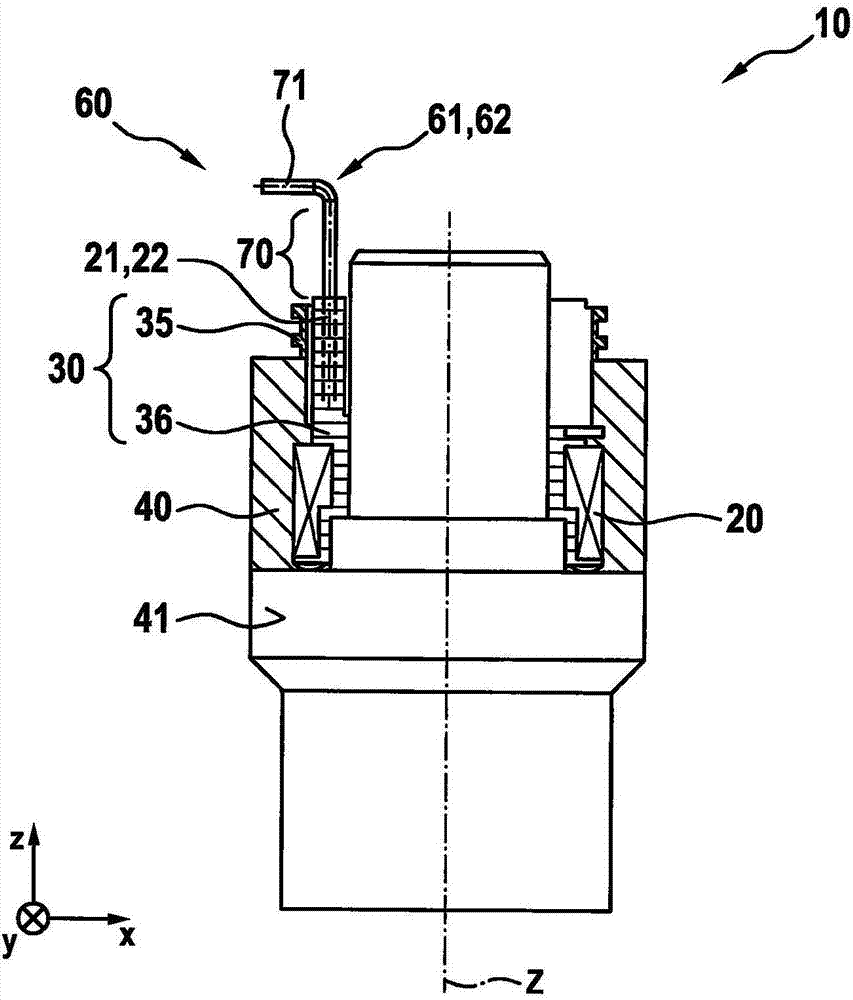

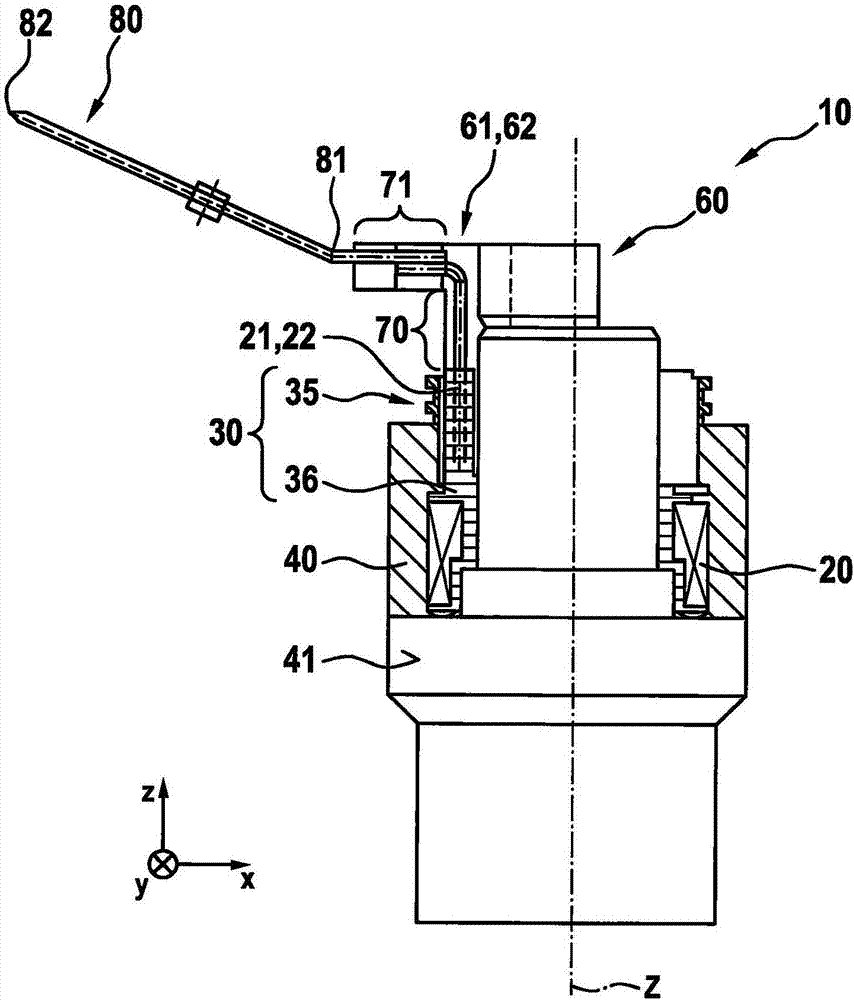

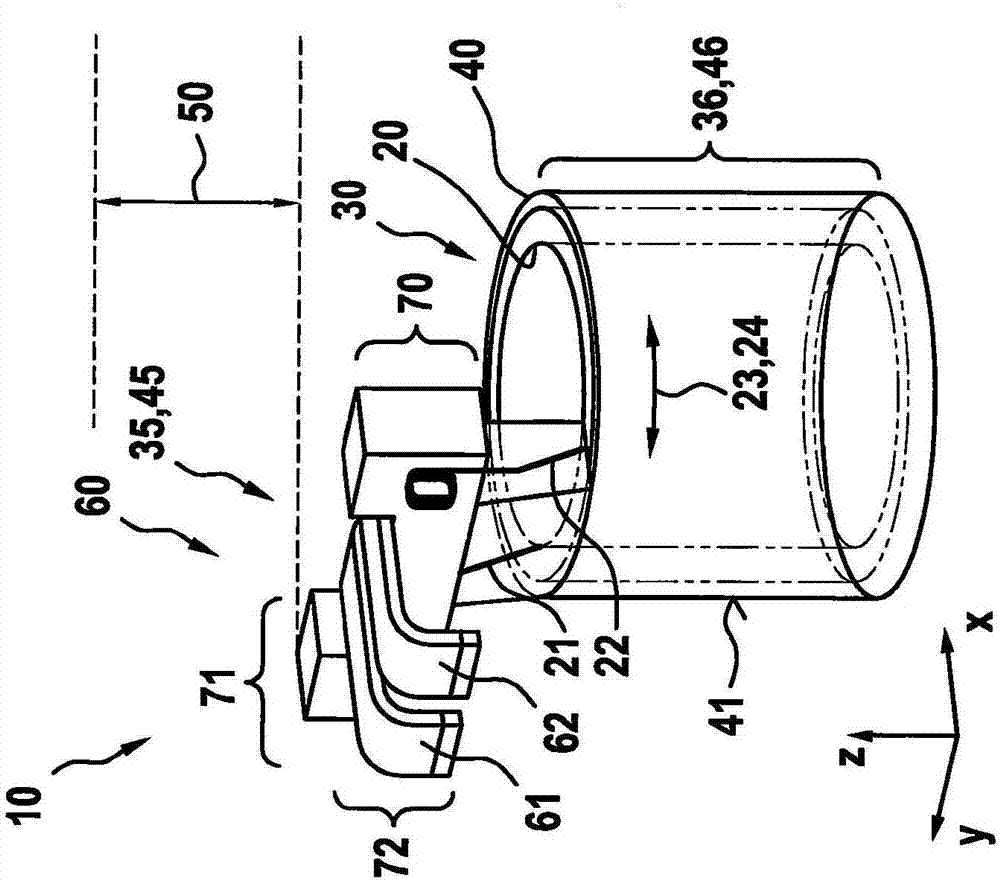

[0036] figure 1 A schematic side sectional view of a first embodiment of a solenoid coil assembly 10 according to the invention is shown.

[0037] figure 1 The solenoid coil assembly 10 has a winding body 30 which can also be referred to as a coil body. The winding body consists of the actual winding region 36 , which carries the coil winding 20 on its outer peripheral surface 31 in the form of sections of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com