Two-column N-row external-driven spherical wheel type garage

A spherical and wheel technology, which is applied in the field of plane mechanical parking equipment, can solve the problems of poor stability and reliability, poor mechanism reliability, and only 40% land utilization rate, and achieve improved steering reliability, convenient wheel steering mechanism, and increased reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

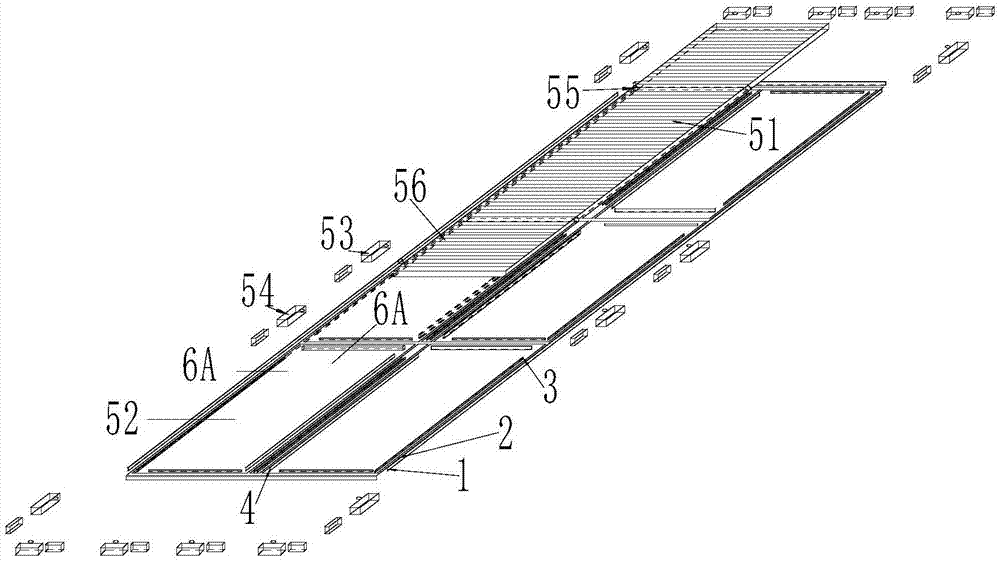

[0045] figure 1 It is a three-dimensional schematic diagram of two rows and N rows of outer drive spherical wheel garages in this embodiment.

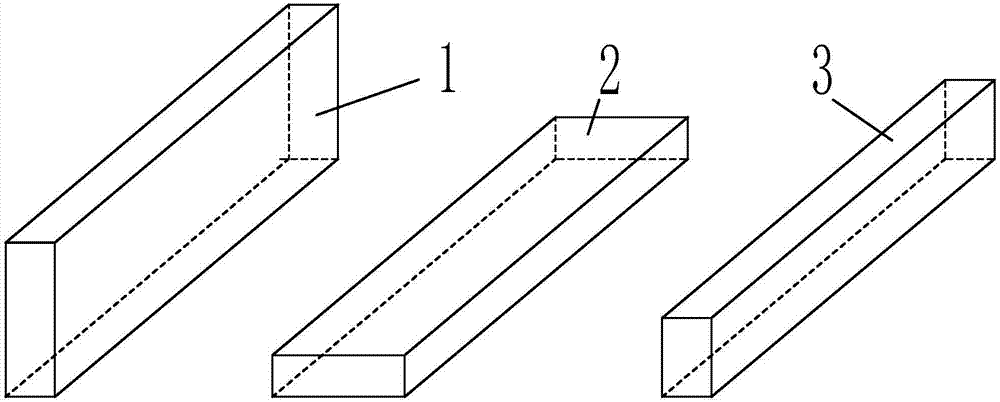

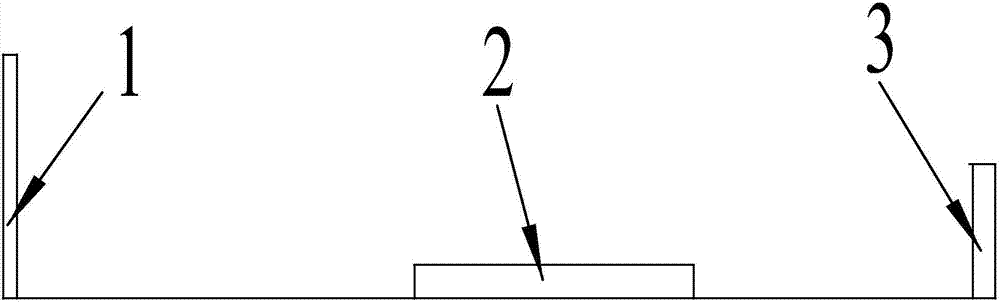

[0046] Such as figure 2 , 3 , Shown in 4, U-shaped groove (6A) has long high block 1, track 2, short block 3 and short high block 4, track 2, short block 3 two kinds of composition modes.

[0047] Such as Figure 5 As shown, the overall shape of the closed horizontal rectangular track system 52 is a rectangle, and four vertical and four horizontal U-shaped grooves 6A divide the rectangle into six small rectangles. The horizontal rectangular track system 52 of row N rows of internal driving spherical wheel garages is made up of four vertical and four horizontal U-shaped grooves 6A, which intersect each other vertically. The high block 4, the track 2 and the low block 3 are formed. U-shaped groove 6A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com