A paper machine wet end exhaust system

A paper machine and wet end technology, applied in the field of paper machine wet end exhaust system, can solve the problems of frequent fan failures, poor exhaust effect, and inability to effectively discharge moisture, so as to improve the on-site environment, eliminate water mist, improve Effects of Convenience and Operational Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

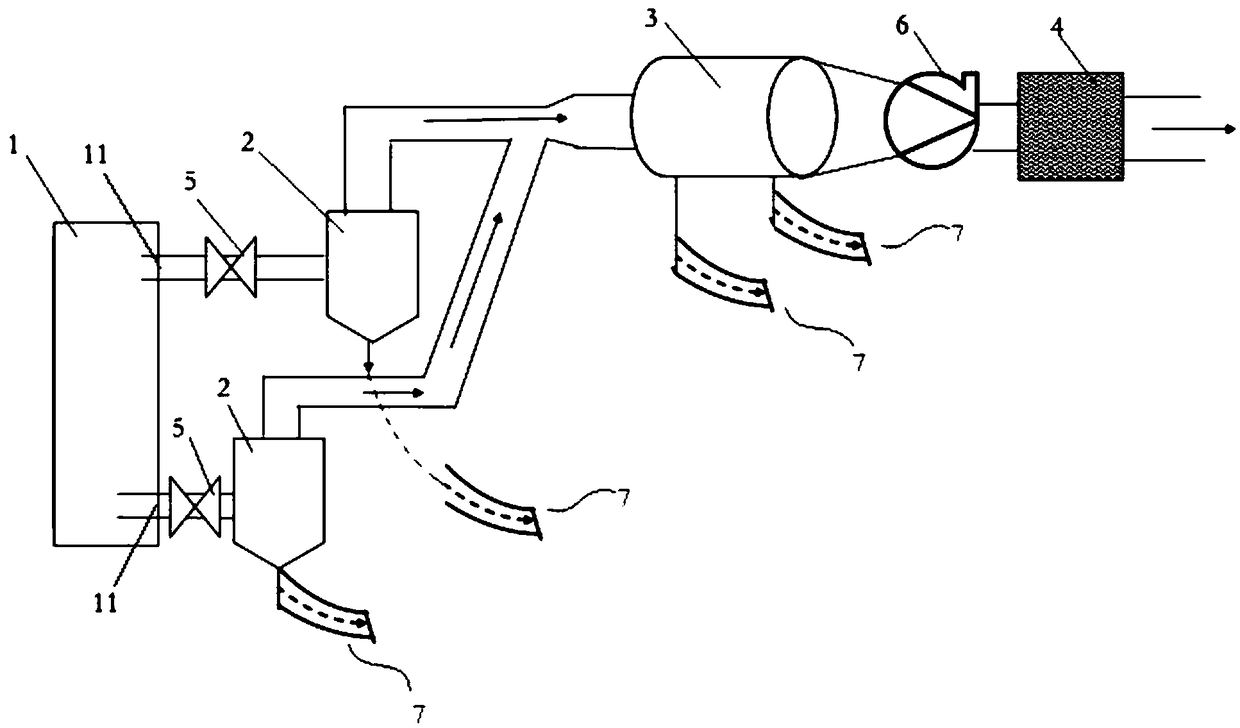

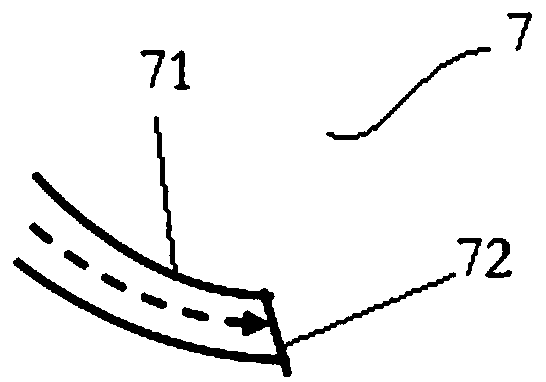

[0028] In one embodiment of the present invention, a paper machine wet end exhaust system is provided, see figure 1 , the system includes a paper machine wire section 1, an air extraction branch pipe, an air extraction main pipe and a blower fan 6, and the paper machine wire section 1 has one or more air outlets 11, and the air extraction branch pipe and the air outlet 11 one-to-one correspondence, figure 1 Only two air outlets 11 are shown in the figure, which are respectively located under the breast roll of the wire section of the paper machine and at the composite roll, but in actual application scenarios, the air outlet 11 may also be arranged under the headbox and tensioned At the roller place, etc., the outlet end of each air extraction branch pipe is connected with the inlet of the air extraction main pipe, and the outlet of the air extraction main pipe is connected with the exhaust fan 6, and the steam and water separation operation is performed by performing air extr...

Embodiment 2

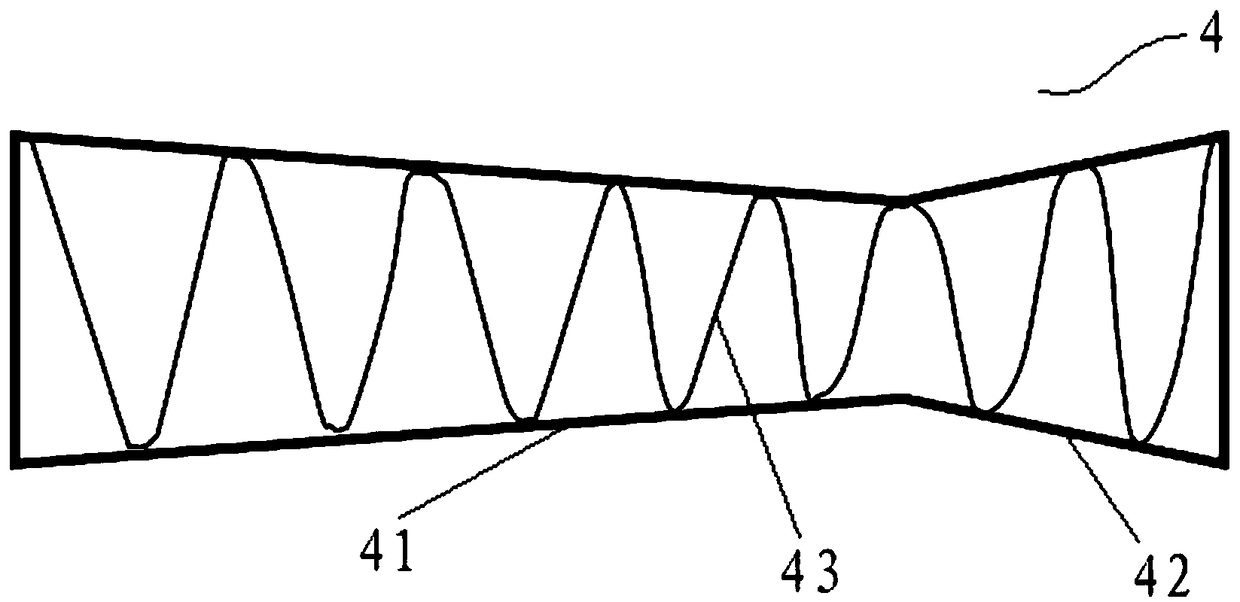

[0036] In another embodiment of the present invention, the fiber separation device 4 includes multiple layers of fiber separation plates arranged sequentially, see Figure 4 , as a preferred embodiment, the fiber separation device 4 includes a first fiber separation plate 44, a second fiber separation plate 45 and a third fiber separation plate 46, as can be seen from the figure, the first fiber separation plate 44 has a right Inclined air guide plate, the second fiber separation plate 45 has a horizontal air guide plate, and the third fiber separation plate 46 has a left-inclined air guide plate. Since adjacent fiber separation plates have wind guide structures in different directions, Therefore, the airflow passing through the fiber separation plate of the previous layer is guided again in the next layer. During the airflow guidance conversion process, the fiber impurities are kept in the fiber separation device 4 to the greatest extent to achieve the purpose of filtering. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com