Anti-cloth-cutting device used for sewing machine and control method of anti-cloth-cutting device

A sewing machine and anti-cutting technology, which is applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing equipment, etc., can solve the problems of fabric damage, fabric not sticking tightly, warping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in further detail below based on the drawings. It should be understood that the specific embodiments described here are merely examples and are not intended to limit the protection scope of the present invention.

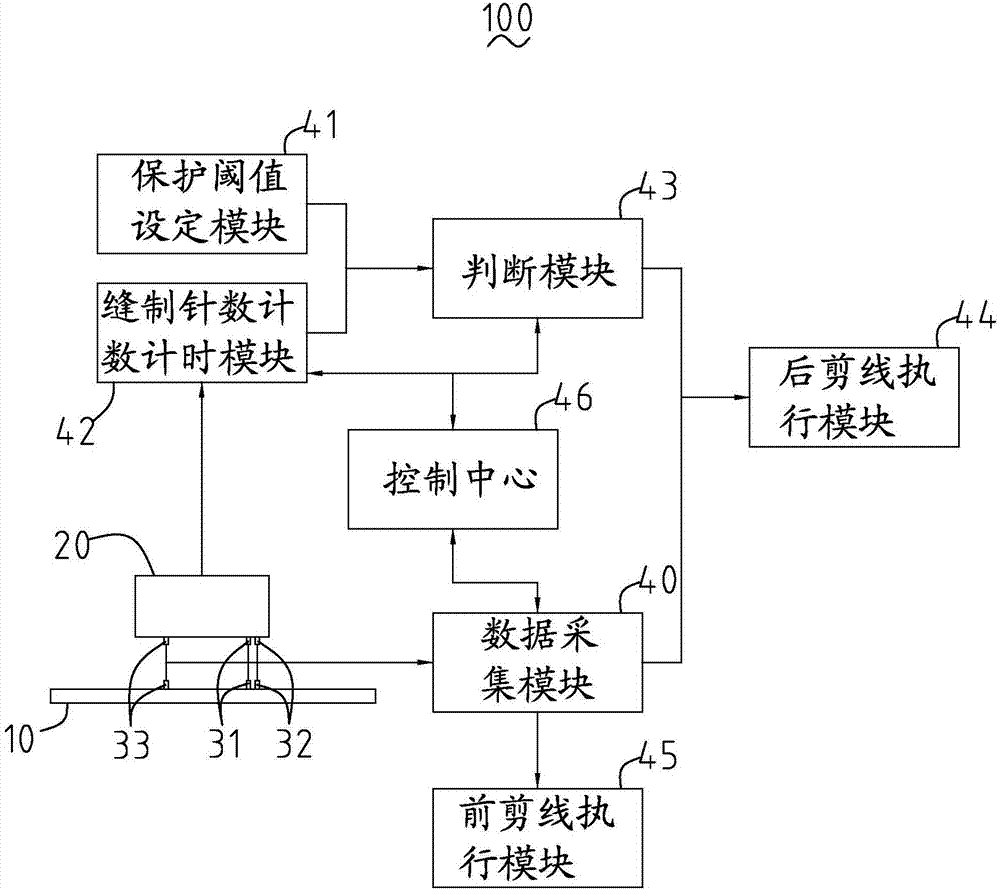

[0023] See figure 1 , Which is a functional block diagram of a cloth cut prevention device 100 for sewing machines provided by the present invention. First of all, it should be noted that, as a sewing machine, it must include a sewing table 10 for placing the fabric to be sewn, a sewing machine 20 for sewing using needles, and at least two first control signals for providing control signals. , The second fabric detection sensor. The structure and working principle of the sewing table 10 and the machine head 20 are well known to those skilled in the art and will not be described in detail. figure 1 Only its schematic diagram is shown in. In this embodiment, the sewing machine includes three fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com