Rotary cutter

A technology of rotary cutting machine and cutting mechanism, which is applied in the direction of metal processing, coiling strips, and sending objects, etc. It can solve the problems of unstable quality of rotary film rotary cutting products, and achieve smooth and stable screw conveying with low friction , Cutting stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the drawings.

[0030] The orientations involved in this specification are based on the orientation of the rotary cutting machine of the present invention when it is working normally, and its storage and transportation orientations are not limited, and only represent relative positional relationships, not absolute positional relationships.

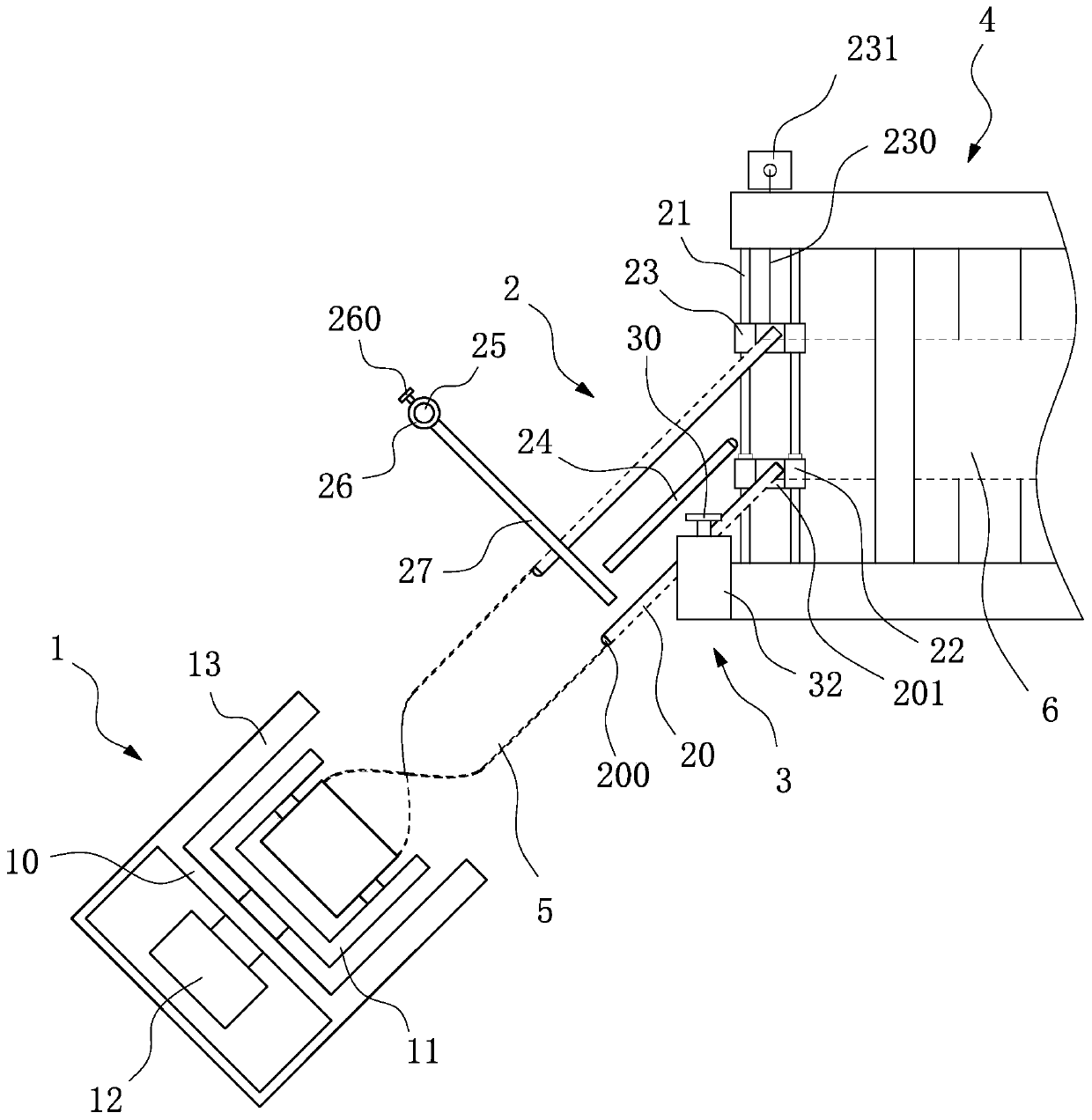

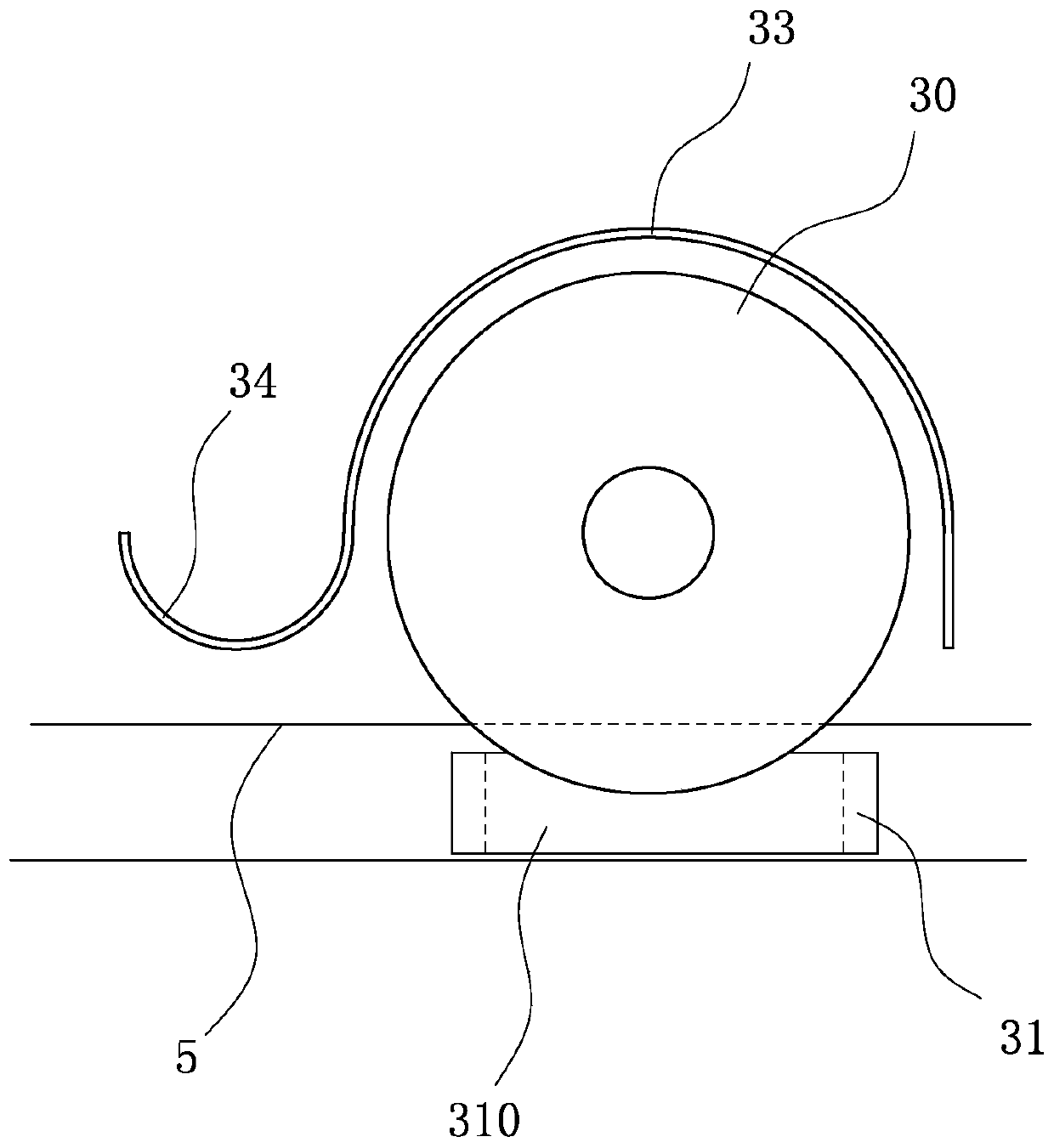

[0031] Such as figure 1 As shown, the rotary cutting machine includes four parts: an unwinding device 1, a guiding mechanism 2, a cutting mechanism 3, and a winding device 4. The roll film 5 is wound on a reel, and the reel is sleeved on the unwinding device 1. The outer end of the tube film 5 is sleeved on the guide mechanism 2, and the tube film 5 is supported by the guide mechanism 2 to form a double-layer flat surface. The cutting mechanism 3 is at a fixed angle with the cutting direction and the guiding direction of the guide mechanism 2. The included angle is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com