Full-automatic packing machine for flat bottom paper bag

A fully automatic packaging machine and paper bag technology, applied in packaging, transportation packaging, packaging protection and other directions, can solve the problem of not being able to meet urgent needs, and achieve the effect of not occupying space, improving packaging speed, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

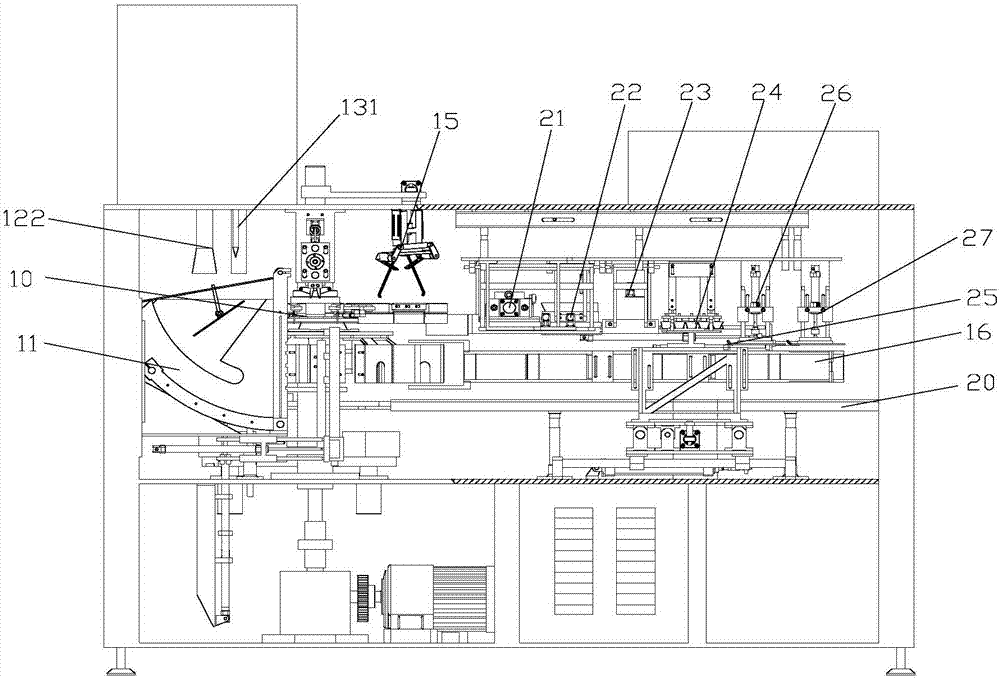

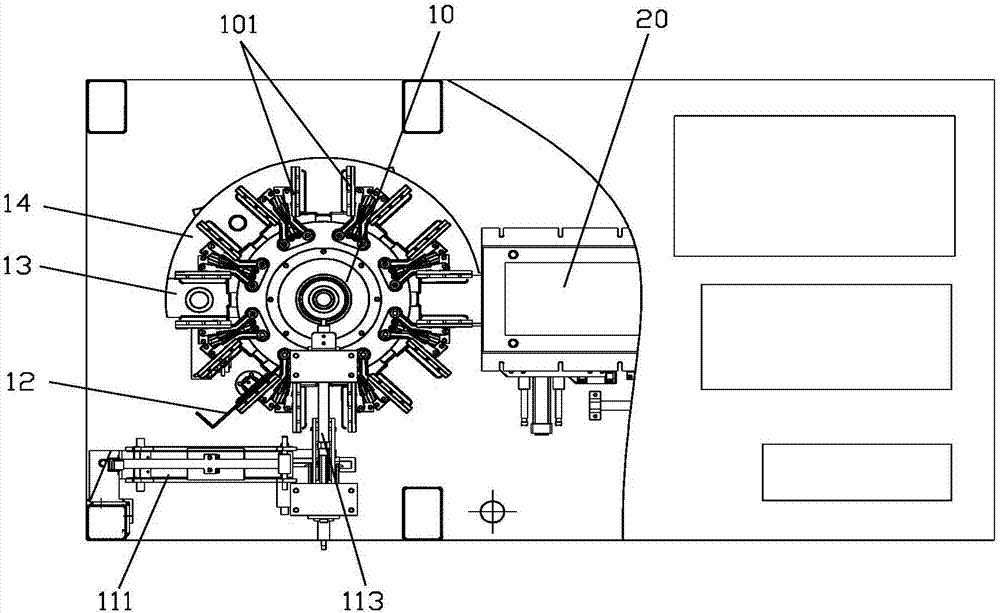

[0039] The present embodiment provides a kind of flat-bottomed paper bag full-automatic packing machine, has such as Figure 1-8 The structure shown includes a bagging device and a bag sealing device.

[0040] The bagging device includes a rotating large plate 10, and the rotating large plate 10 is provided with 8 stations, and its stop position and stop time are controlled by a precision cam divider. Mechanism 11, whole bag mechanism 12, filler mechanism 13, whole material mechanism 14, corner folding mechanism 15 and bag moving mechanism 16, for the convenience of description, the station where bag taking mechanism 11 is located is set as the first rotating station in this embodiment, And by analogy, the structure of the bagging device is described in detail below in conjunction with the accompanying drawings:

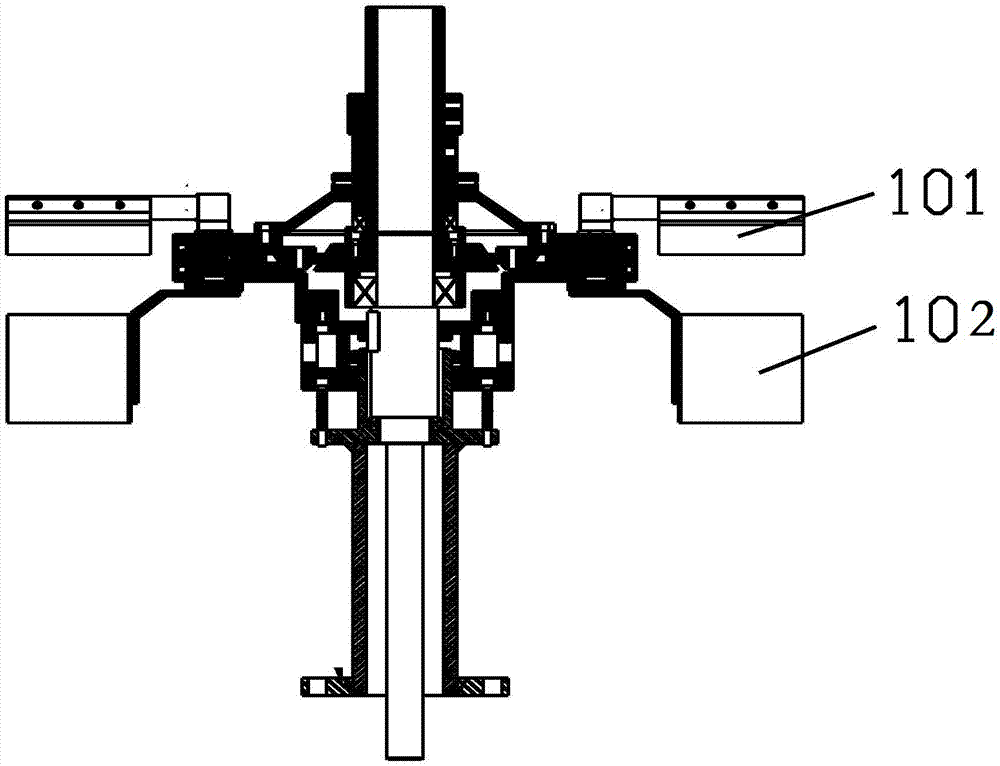

[0041] The station of the rotating large plate 10 includes a bag opening mechanism 101 and a rotating clamping position 102 arranged up and down. The bag opening me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com