Automatic bottled product encasing device

An automatic packing and product technology, applied in the direction of automatic packaging control, type of packaging items, packaging, etc., can solve the problems of low production efficiency, low degree of automation of packaging machinery, inability to achieve large-scale production, etc., to reduce volume and occupation. The space and packing process are convenient and flexible, stable and effective, and the effect of average diversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, three partition plates are provided on the conveying line as an example to describe the following.

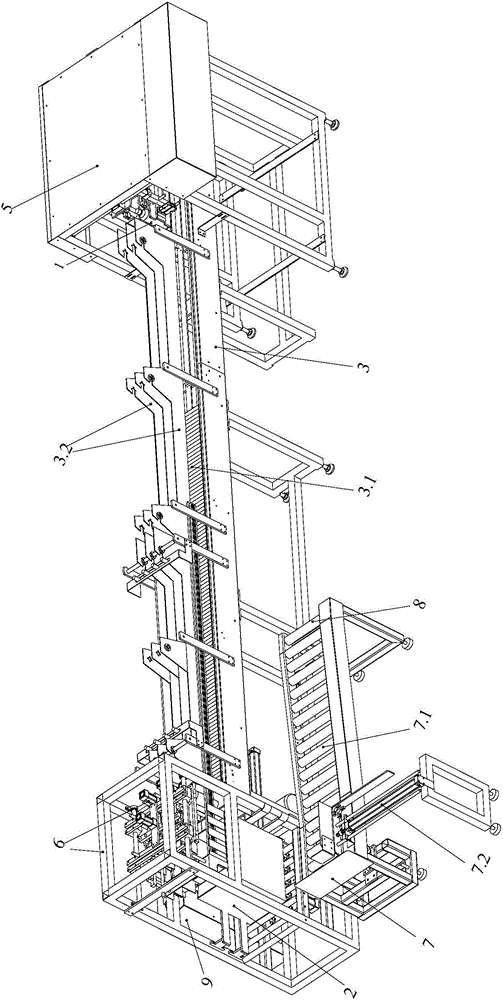

[0048] Such as Figures 1 to 10 As shown, the bottled product automatic packing equipment of the present invention is used to arrange and drop the bottled product 1 into the box body 2; comprising:

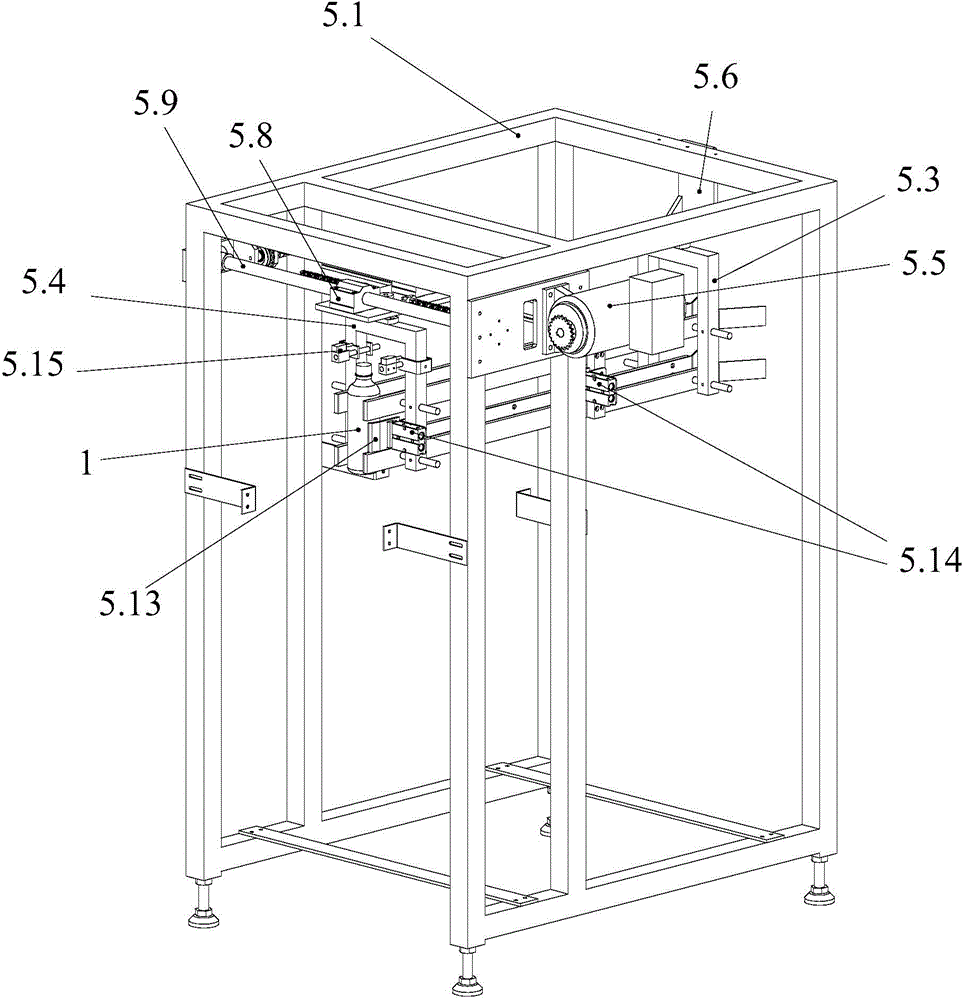

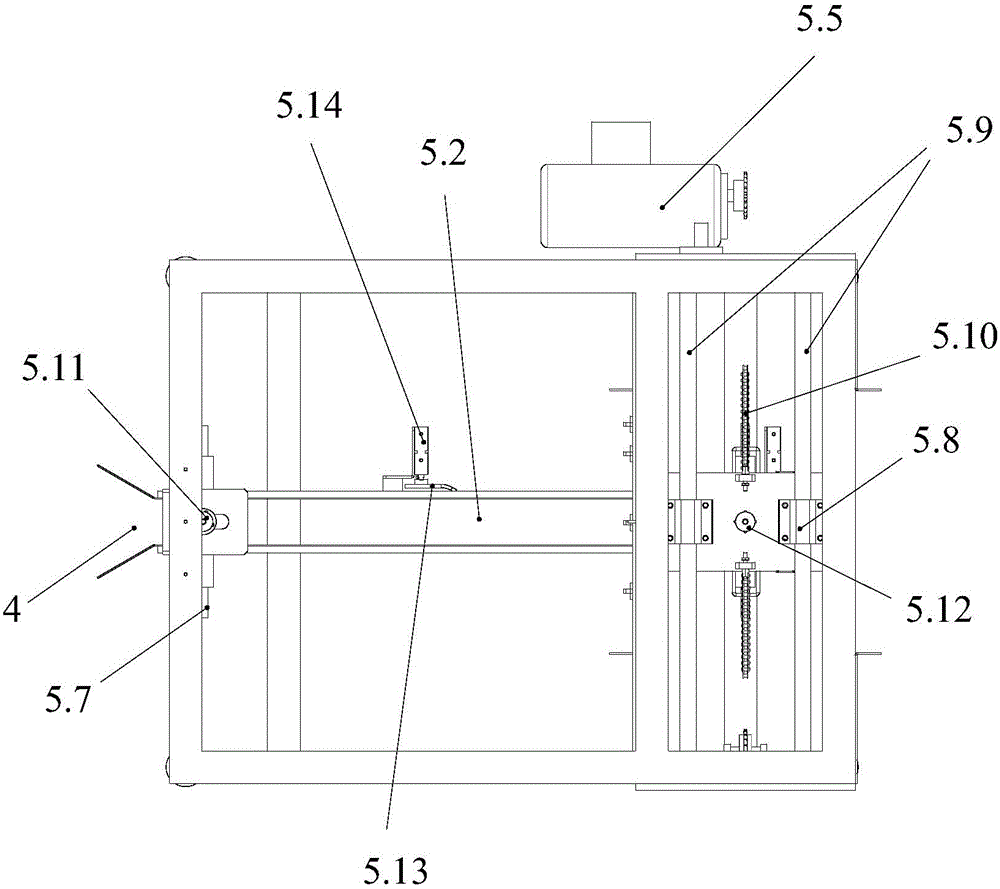

[0049] The bottled product conveying mechanism 3 with 4 conveying channels is used to arrange and guide the conveying according to the number of rows / columns of the bottled products 1 to be preset in the box 2; one end is connected with the equipment inlet 4, and the other end is connected with M conveying Channel movably connected flow diversion mechanism 5, used for mobile diversion of bottled product 1 conveyed from single equipment inlet 4 to 4 conveying passages of bottled product conveying mechanism 3;

[0050] The boxing mechanism 6 connected to the outlet of the bottled product conveying mechanism 3 is used to arrange the bottled products 1 accor...

Embodiment 2

[0067] The only difference between this embodiment and Embodiment 1 is that the conveying mechanism for bottled products in this embodiment can be provided with one, two, three or more partition plates according to production or packing requirements, and the number of partition plates It can be set according to the number of rows / columns of the bottled products to be preset according to the box body. Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com