Welding equipment for cell modules

A battery cell module and welding equipment technology, applied in welding equipment, resistance welding equipment, welding power supply, etc., can solve problems such as poor welding, welding wear of welding head, and false welding, so as to reduce damage or damage and improve production efficiency , Improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

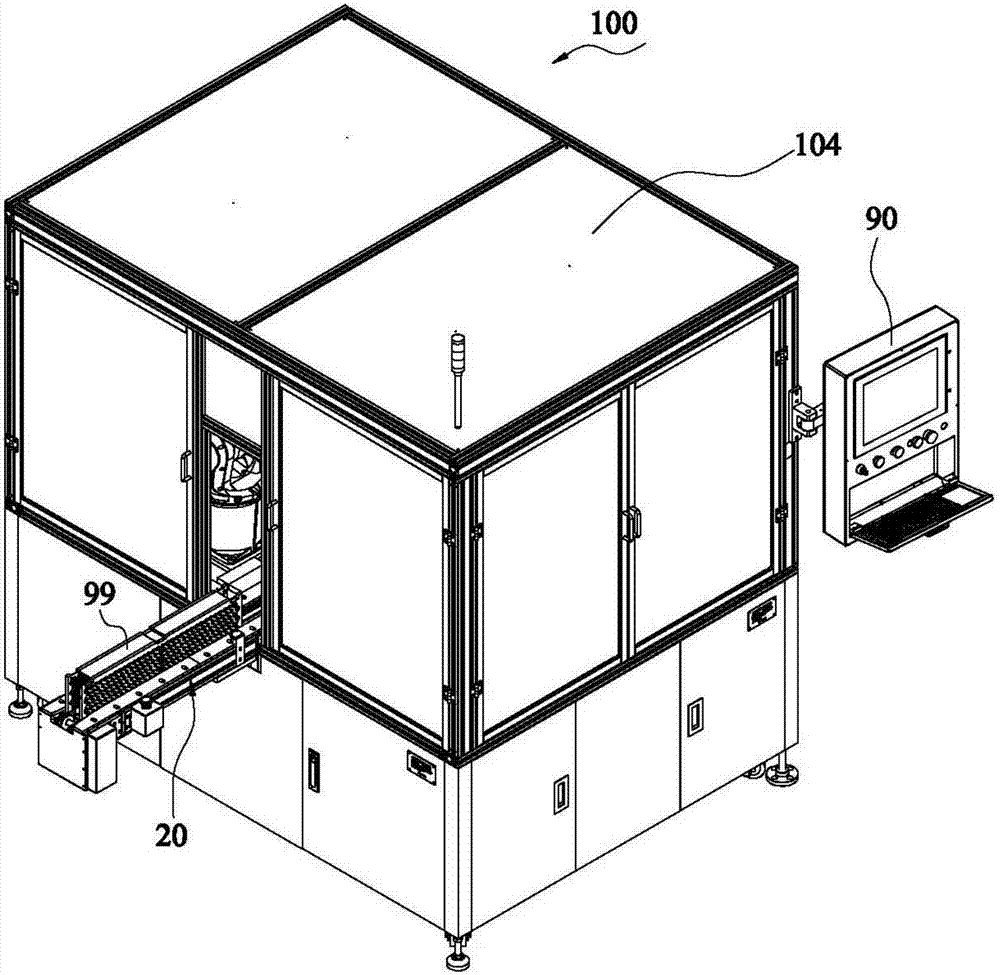

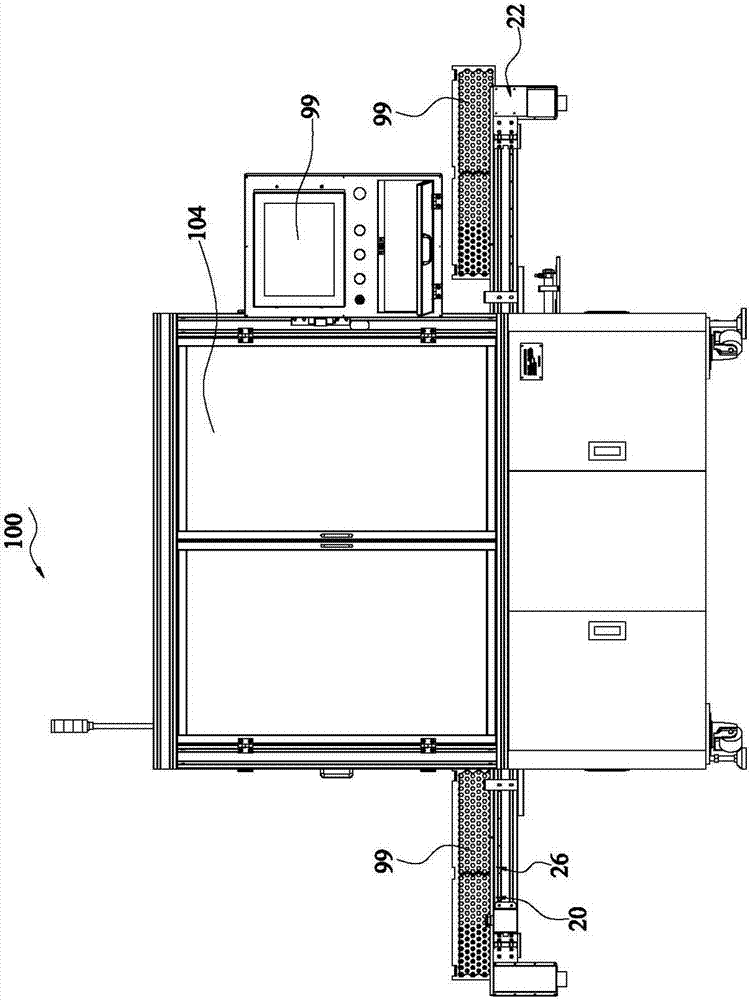

[0033] Such as Figure 1 to Figure 4 As shown, the battery module welding equipment 100 of an embodiment of the present invention includes: a frame 102, a conveying mechanism 20 arranged on the frame 102 to transport the workpiece to be processed, a welding mechanism 40 for welding the workpiece to be processed, a visual Position detection mechanism 60 and control system 90 . The conveying mechanism 20 includes: a feeding mechanism 22 for conveying the parts to be processed for feeding, and a cell module positioning mechanism 24 for receiving the parts to be processed conveyed by the feeding mechanism 22 and positioning the parts to be processed for positioning welding by the welding mechanism 40 .

[0034]The visual positioning detection mechanism 60 locates and finds the first welding spot on the workpiece to be processed, and uses the first welding spot as a reference point to find the relative coordinates of other welding spots. The control system 90 controls the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com